Construction method of long-service-life bridge deck pavement structure capable of preventing bridge deck cracks

A bridge deck paving and construction method technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as easy cracking and damage, and achieve the effects of preventing cracking, strong construction operability, and stress dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A long-life bridge deck pavement construction method for preventing bridge deck cracks, comprising the following steps:

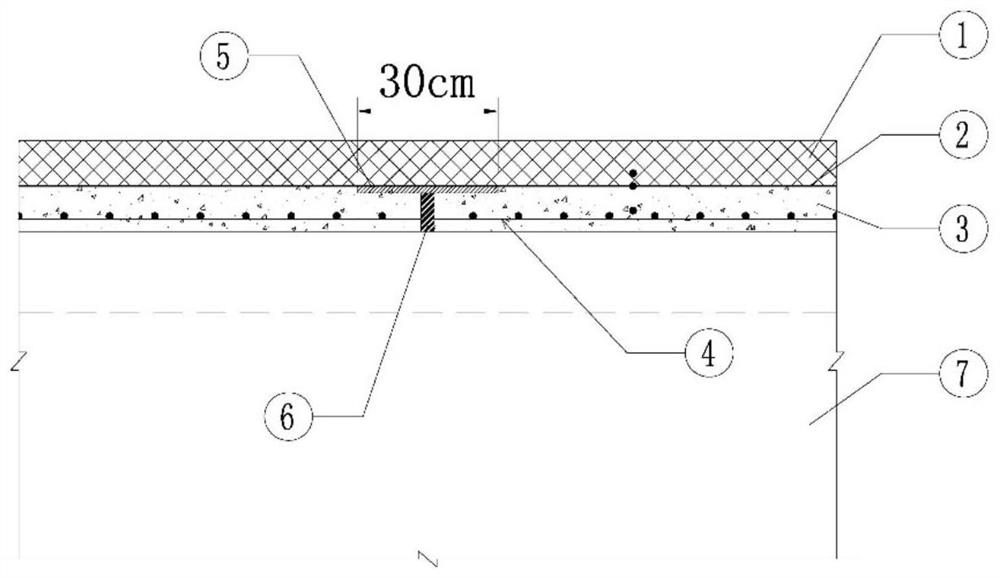

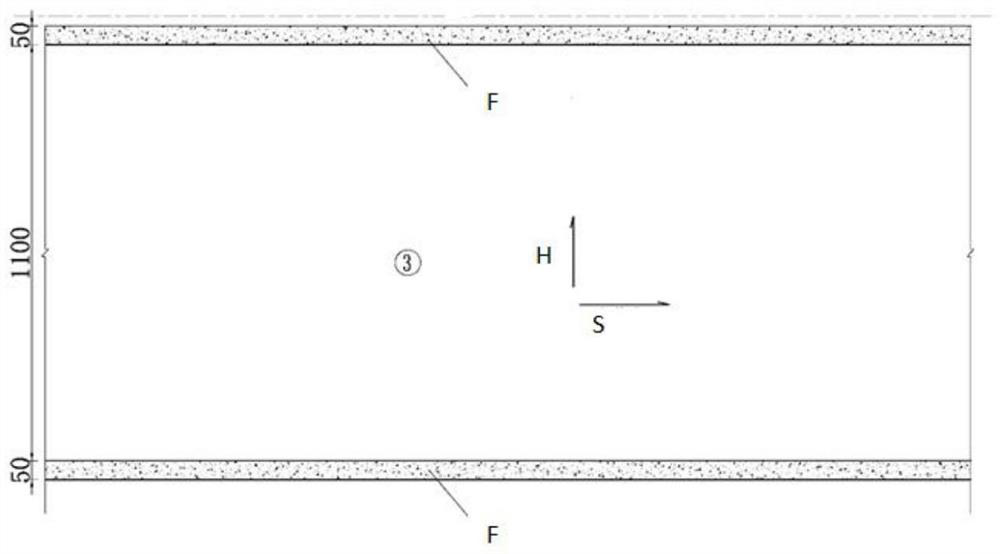

[0028] A. After the erection of the bridge girder is completed, a layer of 10cm thick C50 steel fiber non-shrinkage concrete leveling layer is paved on the bridge deck, and steel mesh pieces with a vertical and horizontal spacing of 10×10cm are set in the leveling layer.

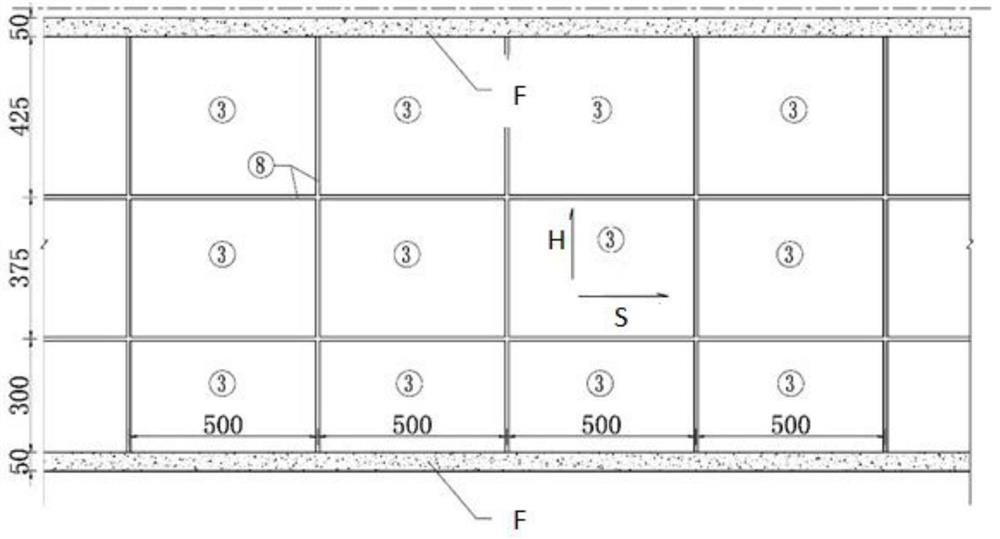

[0029] B. Cut expansion joints with a width of 10mm and an average depth of 100mm on the steel fiber non-shrinkage concrete leveling layer, fill the seam with TST elastic material, and divide the concrete leveling layer into several plates.

[0030] C. Paste a stress-absorbing tape with a width of 30cm on the expansion joint of the concrete leveling layer.

[0031] D. Evenly spread a layer of cement-based permeable crystalline waterproof material on the concrete leveling layer, covering the entire concrete leveling layer, including the pasted stress-absorbing tape.

[0032] E. Pav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com