Forming equipment and process of high frequency straight seam welded steel pipe with intelligent frequency modulation function

A technology for forming equipment and welded steel pipes, which is applied to high-frequency current welding equipment, welding equipment, welding equipment, etc., can solve the problems of general steel pipe forming effect, affect work efficiency, general adaptability, etc., to improve processing quality and intelligent adjustment. Frequency, adaptable effects

Active Publication Date: 2022-06-03

河北华洋钢管有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

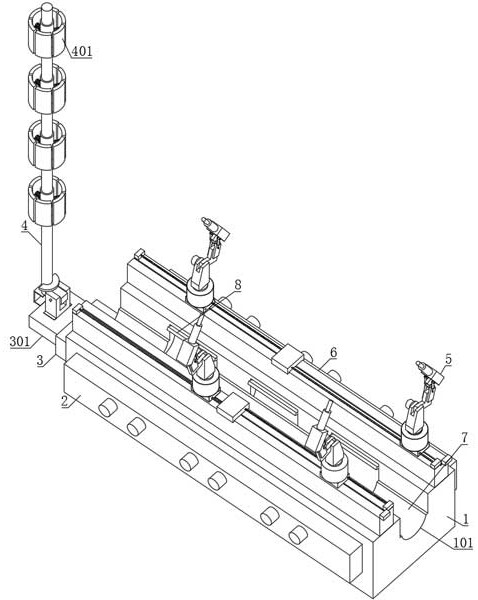

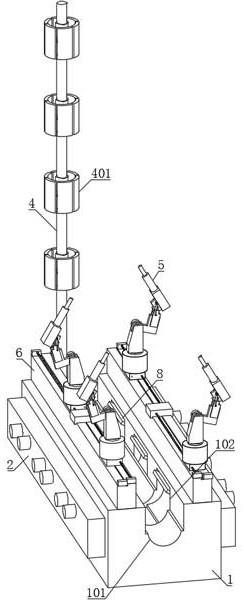

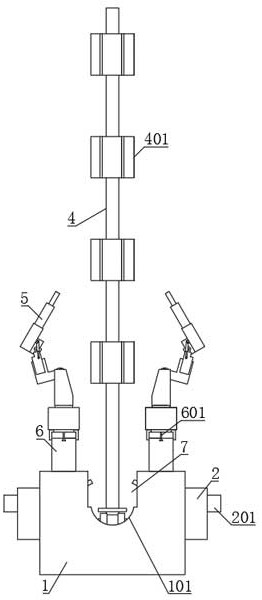

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0038] Below in conjunction with the accompanying drawings in the embodiments of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely

[0042] Further, the upper end of the telescopic plate 301 is installed with a connecting seat 303, and the lower end of the support arm 4 is installed with a movable arm 403,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses high-frequency straight seam welded steel pipe forming equipment and technology with intelligent frequency modulation function, and belongs to the field of straight seam welded steel pipe processing. The forming equipment and process of high-frequency straight seam welded steel pipe with intelligent frequency modulation function of the present invention, the support arm is located on the outside side of the main body of the device, and a connecting sleeve is installed on the outside of the support arm, and the four connecting sleeves The sleeves are surrounded by inner pressurized arc plates, and the high-frequency welding machine includes an electric control box. The invention solves the problems of general steel pipe forming effect, low work efficiency and general adaptability in the forming process of straight seam welded steel pipes in the prior art. The outer wall of the raw material plate of the steel pipe can be pressurized by multiple sets of side pressure ring plates, and the forming work can be carried out in conjunction with the inner pressurized arc plate and the inner limit groove. The inner pressure and the outer pressure are carried out at the same time. Adjust the frequency intelligently according to the welding effect and the collected data.

Description

Forming equipment and process of high frequency straight seam welded steel pipe with intelligent frequency modulation function technical field The present invention relates to the straight seam welded steel pipe processing technical field, be specifically the high frequency straight seam welded steel with intelligent frequency modulation function Tube forming equipment and process. Background technique [0002] A straight seam steel pipe is a steel pipe with the weld seam parallel to the longitudinal direction of the steel pipe. Usually divided into metric electric welded steel pipe, electric welded thin-walled pipe, variable compressor cooling oil pipes, etc. Straight seam welded pipe production process is simple, high production efficiency, low cost, rapid development, high frequency welded pipe unit Using steel coils as raw materials, through a series of longitudinal deformation processes, the strip steel is deformed into an open round tube, which is passed through ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B21C37/08B23K13/02B23K37/053

CPCB21C37/08B23K13/025B23K37/0535Y02P70/10

Inventor 吴秀成刘喜海李腾李勋

Owner 河北华洋钢管有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com