Resistance welding equipment

A technology of resistance welding and equipment, applied in resistance welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as low reliability, low production efficiency, welding quality problems, etc., to ensure welding quality, improve work efficiency, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

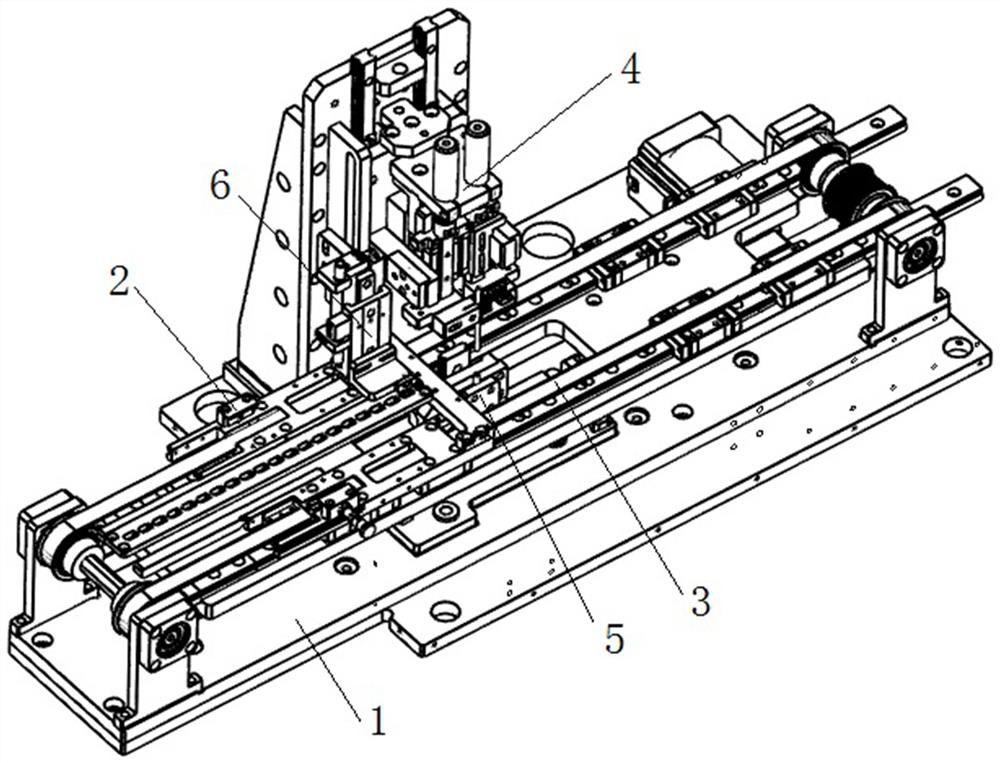

[0018] Such as Figure 1 to Figure 6 As shown, in this embodiment, the present invention includes a machine base 1, a tray positioning module 2, a conveying module 3, an upper welding module 4, a lower welding module 5 and a voltage detection module 6, and the conveying module 3. The upper welding module 4 and the lower welding module 5 are both arranged on the machine base 1, the tray positioning module 2 is arranged on the conveying module 3, and the voltage detection module 6 is arranged on the upper welding module 4, the tray positioning module 2 is located between the upper welding module 4 and the lower welding module 5, and the voltage detection module 6 is located in the tray positioning Module 2 above.

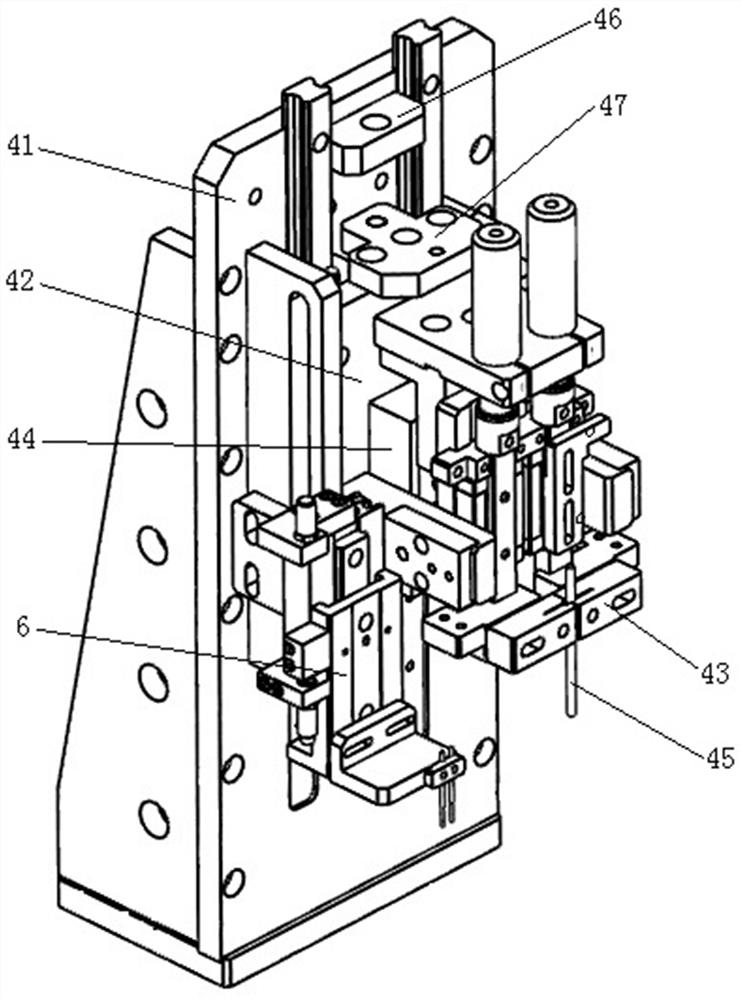

[0019] In this embodiment, the upper welding module 4 includes a support base 41, a mounting plate 42, a mounting base 43, a motor, an adjusting screw, a slide cylinder 44 and an upper welding pin 45, and the support base 41 is arranged on the On the machine base 1,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap