Conveying belt with vibration and falling prevention function for electronic component production

An electronic component, anti-vibration technology, applied in conveyors, transportation and packaging, conveyor control devices, etc., can solve the problems of component body damage, not considering the outer wall structure of electronic components, etc., to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

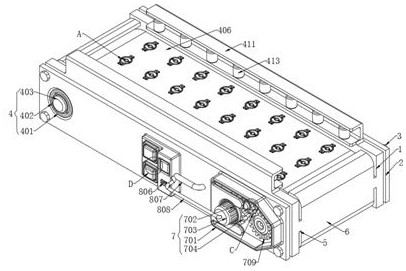

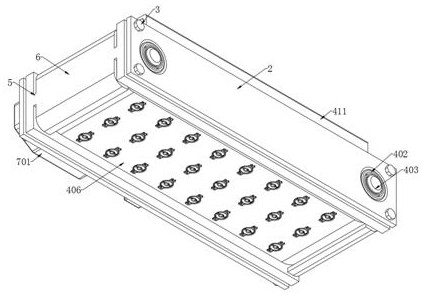

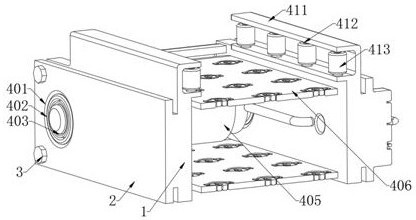

[0037] Example 1, such as Figure 1-9 As shown, the present invention provides a transport conveyor belt with anti-vibration and drop function for the production of electronic components, including: two support plates 1, and a shape protection mechanism 4 is fixedly installed between the two sides of the inner walls of the two support plates 1, A variable speed drive mechanism 7 and a control mechanism 8 are fixedly installed on one side of the outer wall of one of the two support plates 1 .

[0038]Let's talk about the specific settings and effects of its shape protection mechanism 4, variable speed drive mechanism 7 and control mechanism 8 in detail below.

[0039] Such as Figure 1-6 As shown, the outer wall sides of the two support plates 1 are fixed with a reinforced outer plate 2, and the screw 3 runs through the thread between the support plate 1 and the reinforced outer plate 2, and the opposite sides of the two reinforced outer plates 2 are fixedly installed. There ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com