Electromagnetic damping adjustable slip ring and slip shaft system

A technology of electromagnetic damping and slip shaft, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of occupying the programmable controller interface, waste of PLC resources, bloated brush structure, etc., and achieve universal Good performance, avoid waste, simple structure and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

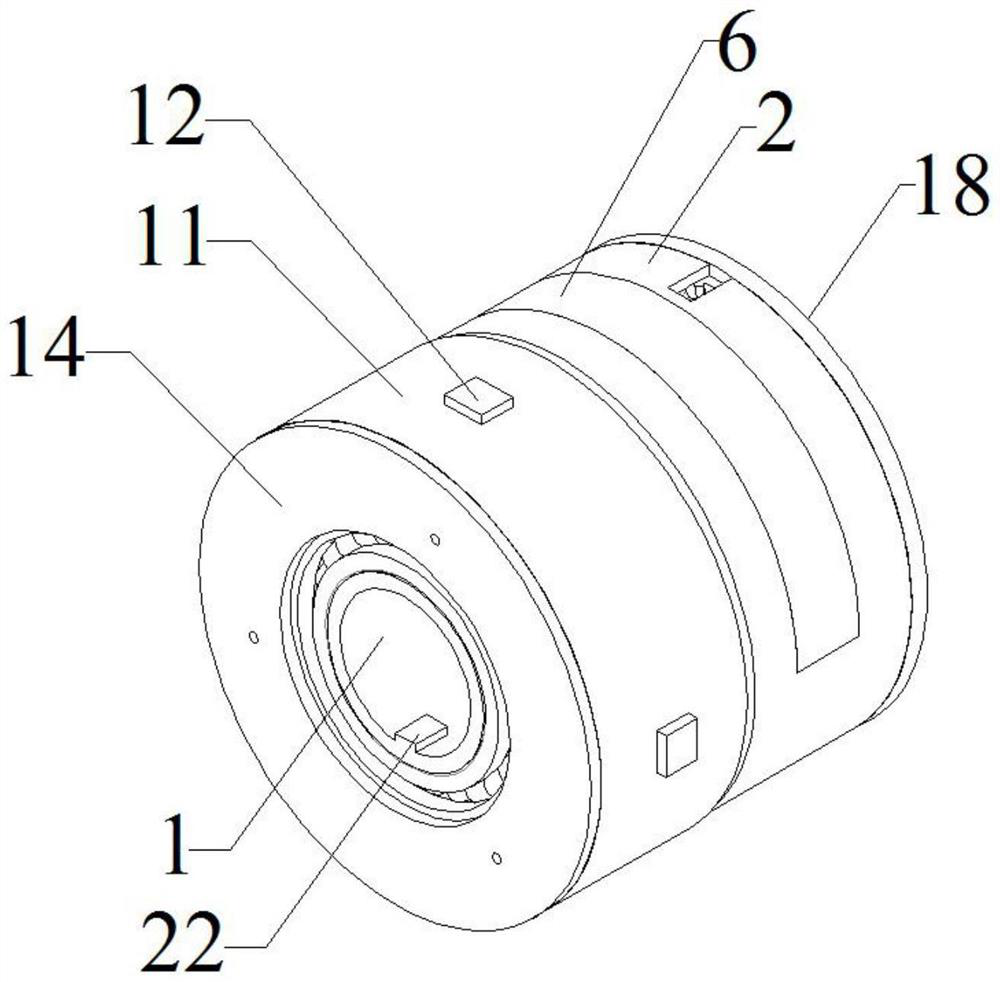

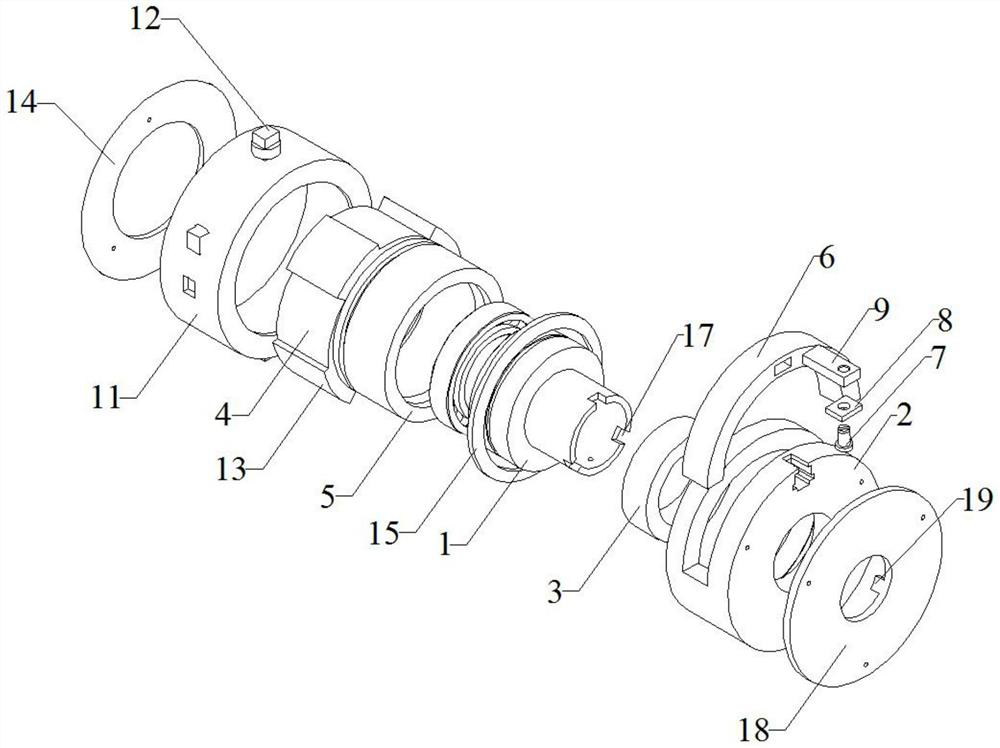

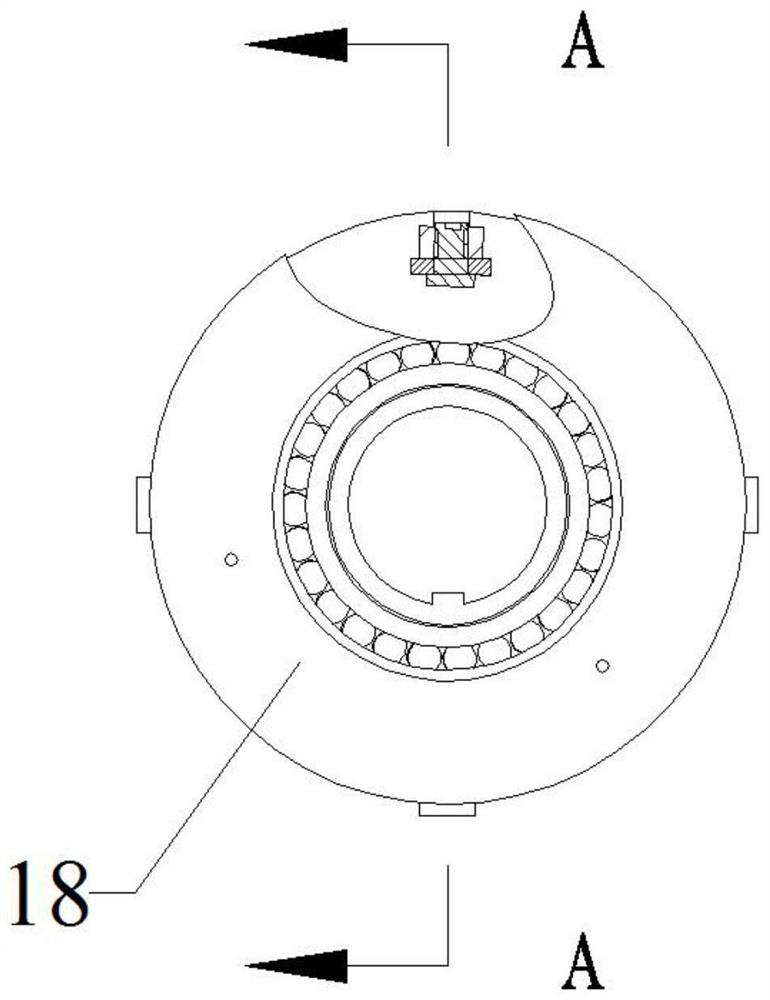

[0044] Such as Figure 1-Figure 12 As shown, the slip ring with adjustable electromagnetic damping in this embodiment includes an inner transmission shaft 1, and the outer surface of the inner transmission shaft 1 is provided with a paper tube fixing assembly and a magnetic transmission assembly that are independent of each other; the magnetic transmission assembly includes a transmission ring 2 and an electromagnetic system for generating electromagnetic force to drive the paper tube fixing assembly to rotate. The drive ring 2 is fixedly connected to the inner drive shaft 1. The electromagnetic system includes magnetic powder. The drive ring 2 is provided with a second space 200 for accommodating the magnetic powder. The drive ring 2 is provided with an electromagnetic damping adjustment assembly for adjusting the gap size of the second space 200.

[0045] In this embodiment, specifically, one end of the transmission ring 2 is fixedly sleeved on one end of the inner transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com