Organic silicon synthetic leather and preparation method thereof

A technology of silicone synthetic leather and mixture, which is applied in the direction of flat products, other household appliances, textiles and papermaking, etc. It can solve the problems of unrealizable materials, localized stress concentration, cracking, etc., and achieve excellent mold release and high-efficiency bonding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

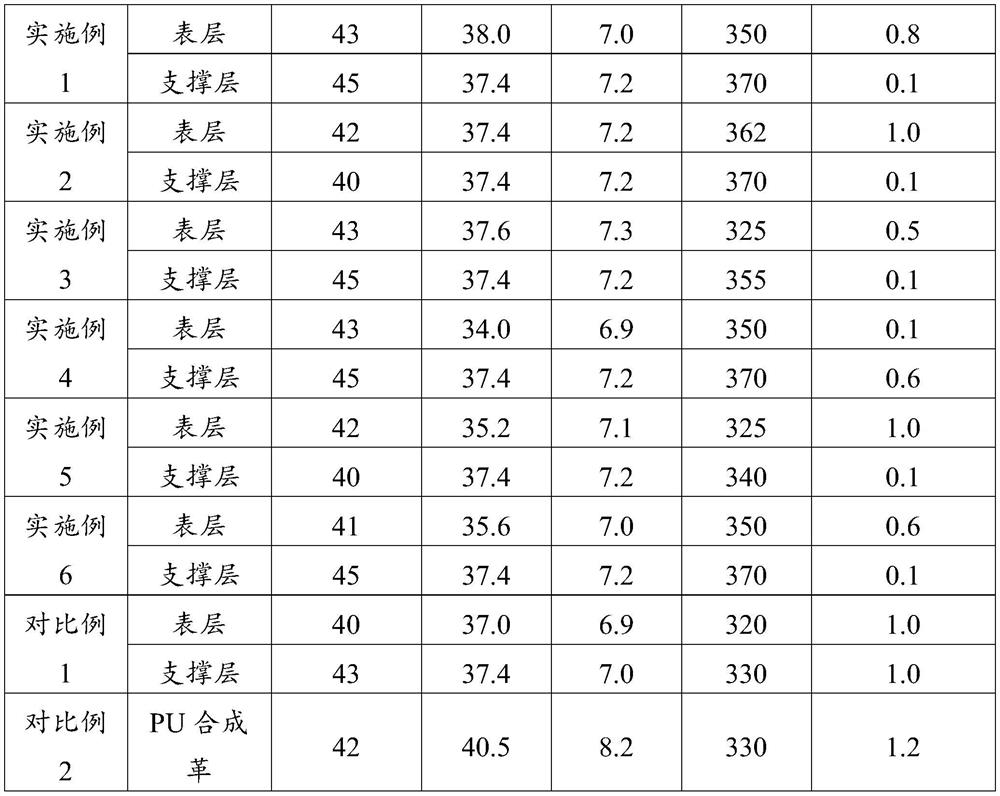

Embodiment 1

[0040] Embodiment 1 of the present invention provides a silicone synthetic leather and a preparation method thereof. Specifically include the following steps:

[0041] (1) Preparation of the basic mixture used in surface layer preparation: under nitrogen protection, add 70 parts of vinyl polydimethylsiloxane with a vinyl content of 0.03% and a viscosity of 50 Pa·s to the kneader, and then add 30 parts of vinyl polydimethylsiloxane with a vinyl content of 2% and a viscosity of 400 Pa·s. Continue to add 30 parts of filler, the specific surface area is 100m 2 / g of precipitated silica, add 30 parts of vinyl MQ silicone resin (vinyl content 1.5%, viscosity 50Pa·s, Me in silicone resin 3 SiO 1 / 2 with SiO 4 / 2 The ratio of the group is 0.6), add 30 parts of spherical MQ silicone resin (viscosity is 12.5Pa·s, Me in the silicone resin 3 SiO 1 / 2 with SiO 4 / 2 The ratio of the group is 1.25) Stir and mix in a kneader, keep the system temperature not higher than 60°C during the whol...

Embodiment 2

[0048] Embodiment 2 of the present invention provides a silicone synthetic leather and a preparation method thereof. Specifically include the following steps:

[0049] (1) Preparation of the basic mixture used in surface layer preparation: under nitrogen protection, add 50 parts of vinyl polydimethylsiloxane with a vinyl content of 0.08% and a viscosity of 200 Pa·s to the kneader, and then add 50 parts of vinyl polydimethylsiloxane with a vinyl content of 1% and a viscosity of 200 Pa·s. Continue to add 40 parts of alumina as filler, add 20 parts of vinyl MQ silicone resin (vinyl content 0.5%, viscosity 12.5Pa·s, Me in silicone resin 3 SiO 1 / 2 with SiO 4 / 2 The ratio of the group is 1), add 40 parts of spherical MQ silicone resin (viscosity is 20Pa·s, Me in the silicone resin 3 SiO 1 / 2 with SiO 4 / 2 The ratio of the group is 0.6) Stir and mix in a kneader, keep the system temperature not higher than 60°C during the whole process; after mixing evenly, stir for 0.5h in an env...

Embodiment 3

[0056] Embodiment 3 of the present invention provides a silicone synthetic leather and a preparation method thereof. Specifically include the following steps:

[0057] (1) Preparation of the basic mixture used in surface layer preparation: under nitrogen protection, add 30 parts of vinyl polydimethylsiloxane with a vinyl content of 0.06% and a viscosity of 400 Pa·s to the kneader, and then add 70 parts of vinyl polydimethylsiloxane with a vinyl content of 0.5% and a viscosity of 400 Pa·s. Continue to add 20 parts of alumina with a specific surface area of 0.00000000000000000000000000000000000000000000000000. 3 SiO 1 / 2 with SiO 4 / 2 The ratio of the group is 1.5), add 35 parts of spherical MQ silicone resin (viscosity is 1Pa s, Me in the silicone resin 3 SiO 1 / 2 with SiO 4 / 2 The ratio of the group is 1) Stir and mix in a kneader, and keep the system temperature not higher than 60°C during the whole process; after mixing evenly, stir for 1 hour in an environment not highe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com