Oil-water cooling bearing

A bearing, oil-water technology, applied in bearing components, shafts and bearings, bearing cooling, etc., can solve the problems of large space occupation, inability to operate electromechanical equipment, complex equipment composition, etc., achieve high cooling efficiency, optimize cooling and lubrication scheme , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

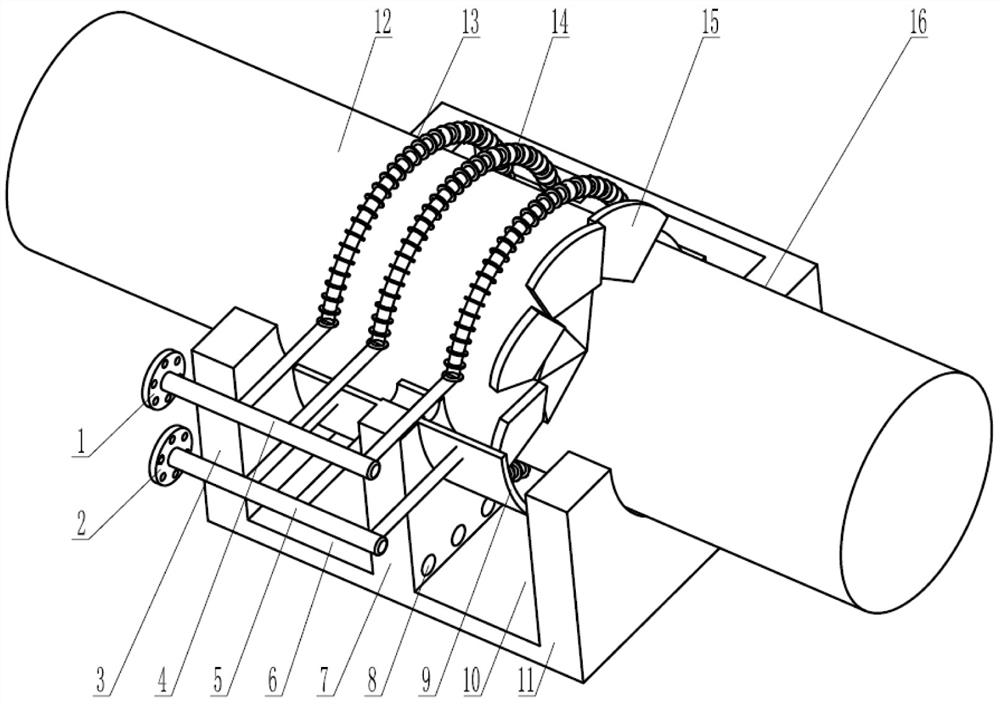

[0013] figure 1 Shown is the structural composition of the water-cooled bearing of the present invention. In order to show the internal structure, the front part and the upper half of the support plate are hidden in the figure. The water-cooled bearing mainly includes a water inlet 1, a water outlet 2, a left support plate 3, Inlet water collector 4, water outlet water collector 5, left oil chamber 6, middle partition 7, through hole 8, cylinder 9, right oil chamber 10, right support plate 11, bearing body 12, left Bearing bush 13, cooler 14, blade 15 and right side bearing bush 16 and other parts.

[0014] The left and right sides of the bearing seat are respectively the left support plate 3 and the right support plate 11, and the middle part is the middle partition plate 7. The middle partition plate 7 divides the oil chamber inside the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com