Experimental device and method for spacing between inner layer and outer layer of LNG tank body

An experimental device and a technology of inner and outer layers, applied in the field of experimental devices for the distance between the inner and outer layers of LNG tanks, can solve the problems of high production cost, large volume and weight of the tank, and achieve the effects of saving energy, improving sealing performance, and saving experimental time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

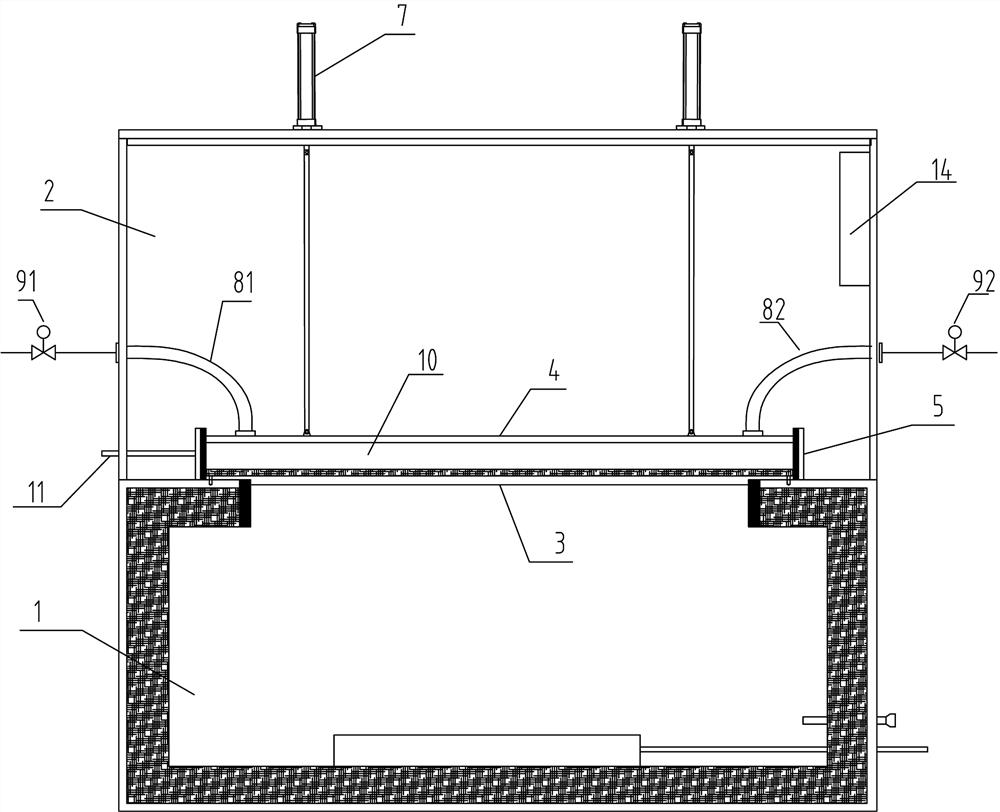

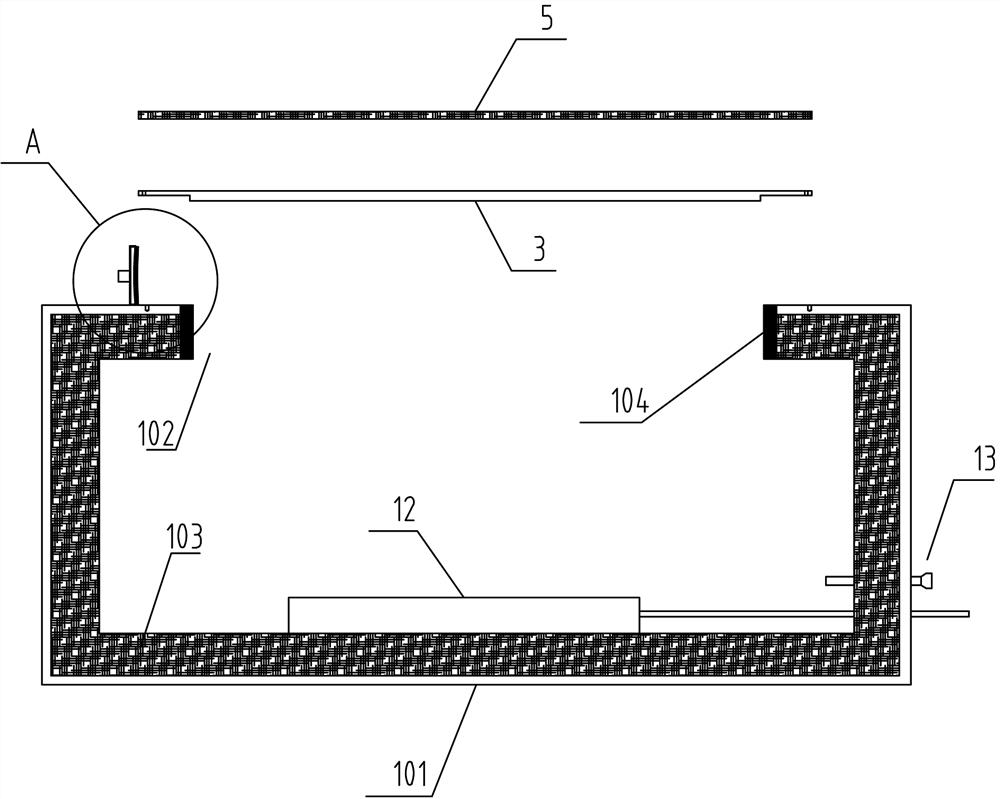

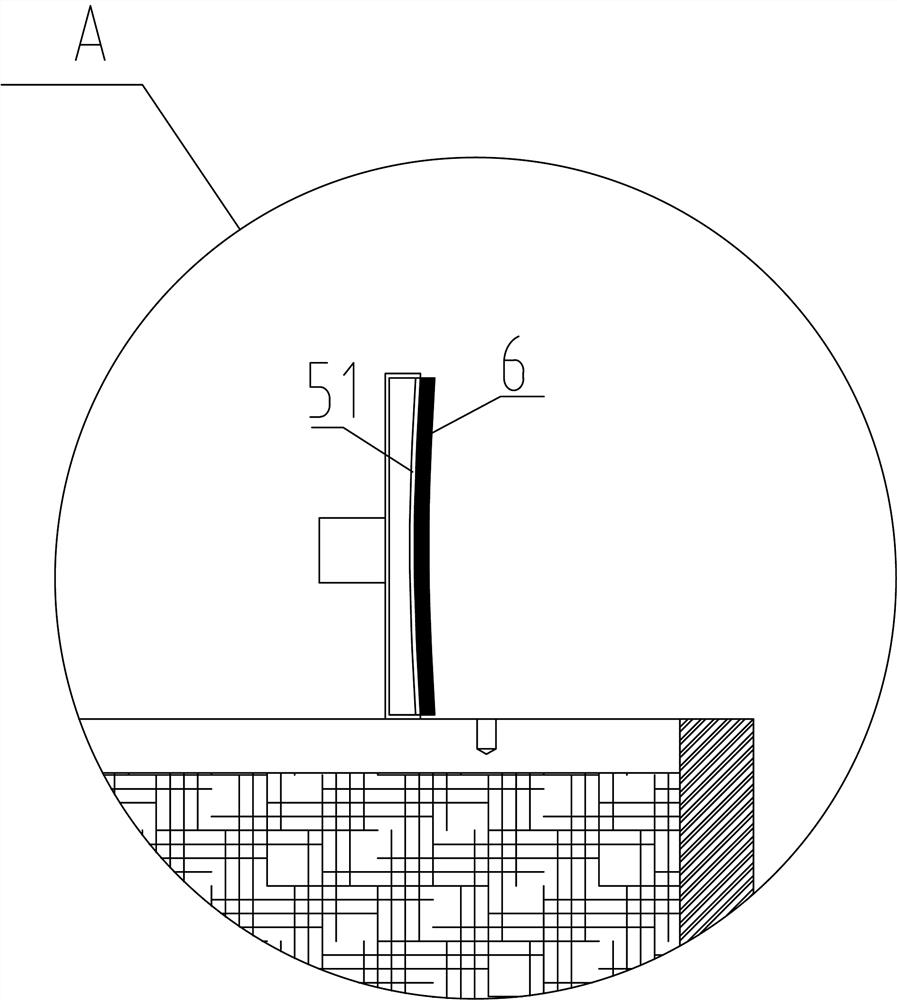

[0033] The preferred solution is as Figure 1 to Figure 5 As shown, an LNG tank inner and outer layer spacing experiment device includes a low-temperature chamber 1 and a normal chamber 2, the low-temperature chamber 1 includes a low-temperature chamber shell 101, the top of the low-temperature chamber shell 101 is provided with an experimental opening 102, and the inner wall of the low-temperature chamber shell 101 is provided with The main heat insulation layer 103 of the low-temperature chamber, the edge of the experiment opening 102 is provided with the heat insulation layer 104 of the experiment position; the experiment opening 102 is provided with the simulation board 3 of the inner cylinder of the LNG tank, and the outer edge of the simulation board 3 of the inner cylinder of the LNG tank is connected to the top of the shell 101 of the low-temperature chamber; The top of the low-temperature chamber shell 101 is provided with a limiting frame 5, the inner cylinder simulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com