Device and method for evaluating thixotropic property of fresh concrete

A technology for evaluating devices and concrete, applied in measurement devices, flow characteristics, instruments, etc., can solve problems such as the inability to characterize the cohesion of fresh concrete and the inability to consider the plasticity of concrete, and achieves good real-time detection, wide application range, and operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

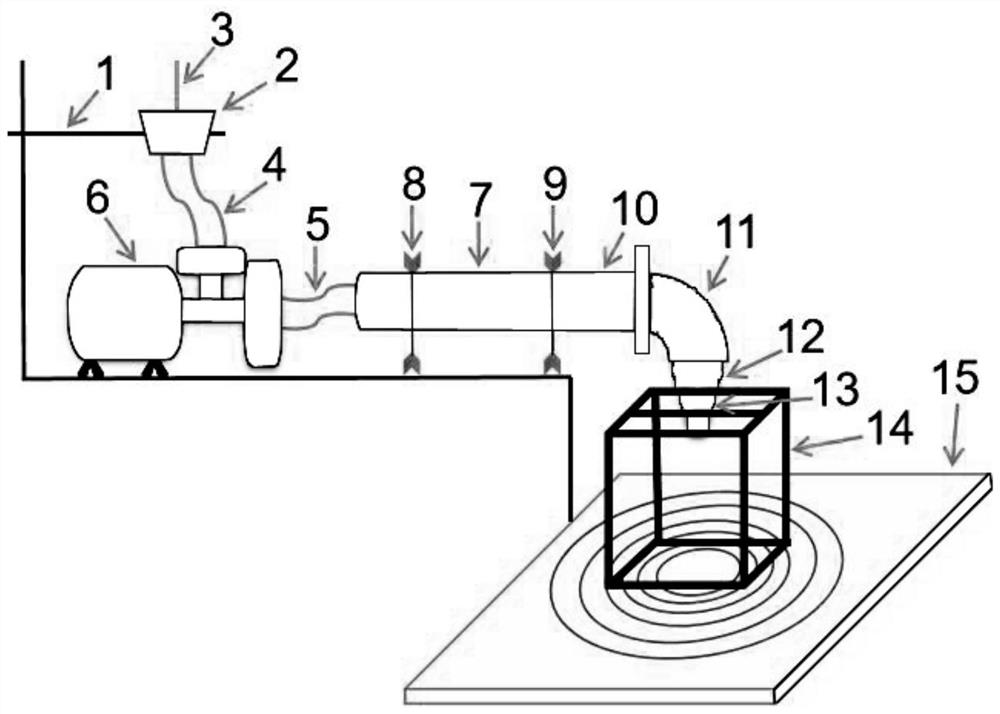

[0033] as attached figure 1 As shown, a thixotropic performance evaluation device for fresh concrete includes a collecting hopper 2 fixed on a fixed bracket 1, and the collecting hopper 2 is connected with a diaphragm pump 6 through a first stainless steel braided pipe 4, and the diaphragm pump 6 is also passed through a second The stainless steel braided pipe 5 is connected with the horizontal conveying steel pipe 7, and the horizontal conveying steel pipe 7 is provided with a pressure sensor 10, and the horizontal conveying steel pipe 7 is connected to the discharge nozzle 12 through the stainless steel bend 11, and the discharge nozzle 12 is provided with a flowmeter 13. A stainless steel frame 14 is arranged below the feed nozzle, and a small support for assisting in supporting the discharge nozzle is arranged on the stainless steel frame 14 , and the stainless steel frame 14 is placed on the glass plate 15 .

[0034] The horizontal conveying steel pipe is fixed by the fir...

Embodiment 2

[0037] This embodiment provides a method for evaluating the thixotropic performance of fresh concrete. In order to facilitate the description of the method for evaluating the thixotropic performance of fresh concrete in this embodiment, the device for evaluating the thixotropic performance of fresh concrete is divided into concrete feeding areas , Concrete conveying area, concrete discharging area and concrete thixotropic performance testing area, wherein the concrete feeding area includes a collecting hopper and a rotating shaft; the concrete conveying area includes a stainless steel metal braided hose at the lower end of the collecting hopper, a pneumatic diaphragm pump and a horizontally placed Stainless steel pipes; the concrete discharge area includes stainless steel bends and discharge nozzles; the concrete thixotropic performance test area includes stainless steel frames and glass plates.

[0038] In this embodiment, the collecting hopper is a small stainless steel inver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com