Battery box for detecting battery liquid leakage and processing technology thereof

A processing technology and battery box technology, which is applied in the field of battery boxes for detecting battery leakage and its processing technology, can solve the problems of inconvenient battery box and battery work, and achieve the effect of avoiding deformation and being easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

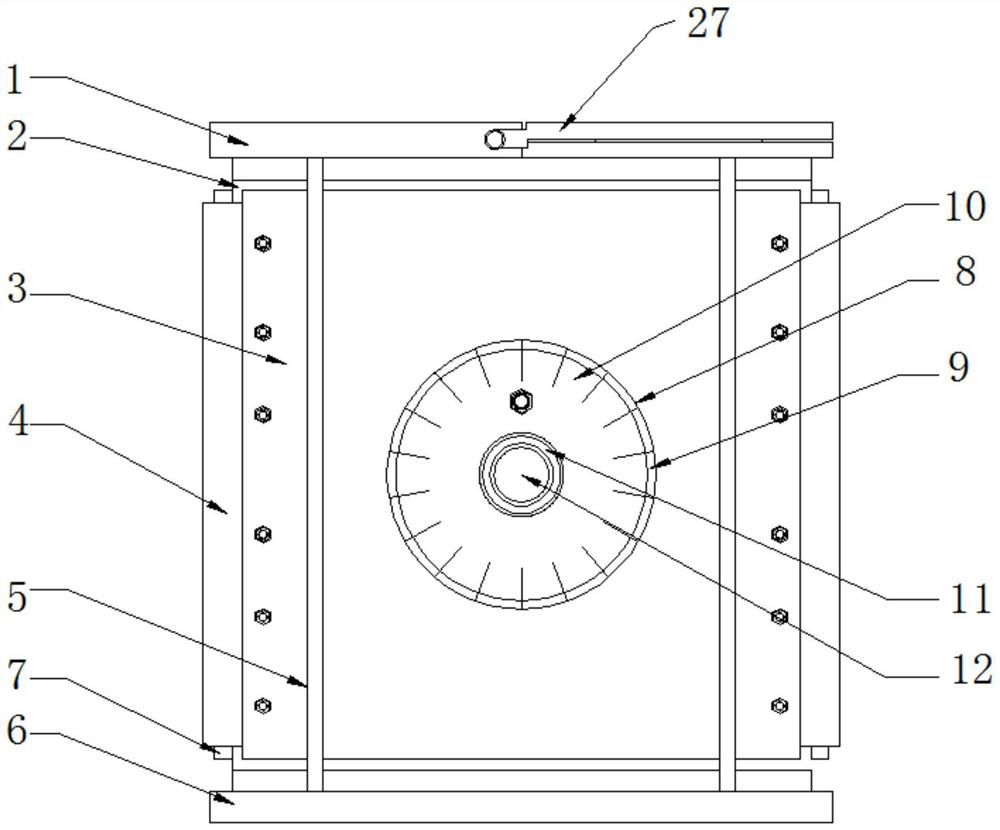

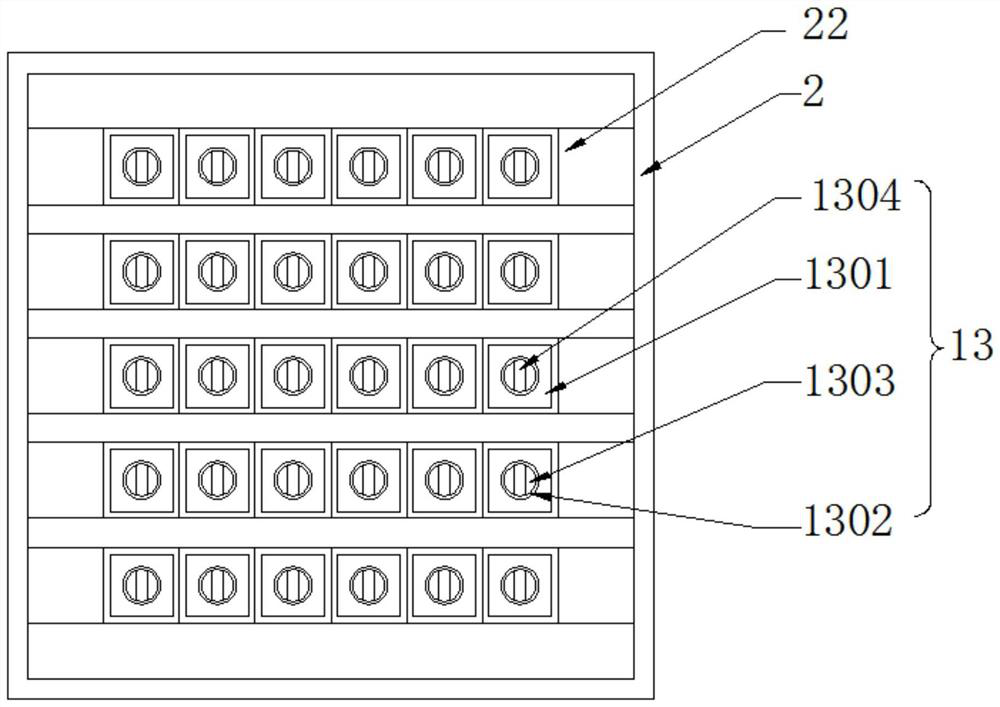

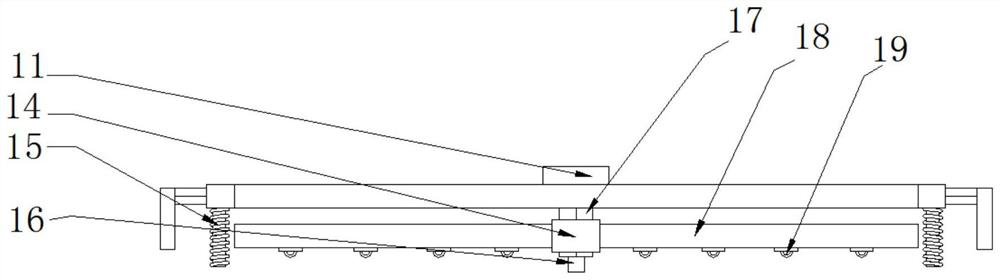

[0033] see Figure 1 to Figure 5 , the present invention provides a technical solution: a battery box for detecting battery leakage and its processing technology, including an upper cover 1, a battery box 2, an external cover 3, a built-in plate 4, an external reinforcement column 5, a lower bottom cover 6, Radiating bar 7, angle plate 8, connection cavity 9, center sleeve plate 10, rotating shaft 11, temperature display dial 12, detection component 13, partition frame 1301, built-in compartment 1302, cover plate 1303, test strip 1304, connection Cover plate 14, fixed spring 15, temperature test probe 16, extension rod 17, auxiliary inner plate 18, camera 19, auxiliary component 20, mounting plate 2001, auxiliary channel 2002, fixed top cover 21, battery upper support frame 22, battery 23 , built-in reinforcing column 24, battery lower support frame 25, fixed bottom cover 26 and battery handle 27, the left end of loam cake 1 is rotated and installed with battery handle 27, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com