Adjustable mine environment-friendly dust removal equipment

A dust removal equipment and adjustable technology, applied in the direction of external electrostatic separator, steam flow control, electrostatic separation, etc., can solve the problems of waste of resources, damage to the respiratory tract, inability to deal with slag dust, etc., to achieve energy saving and environmental protection, reduce workload, The effect of improving safety and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

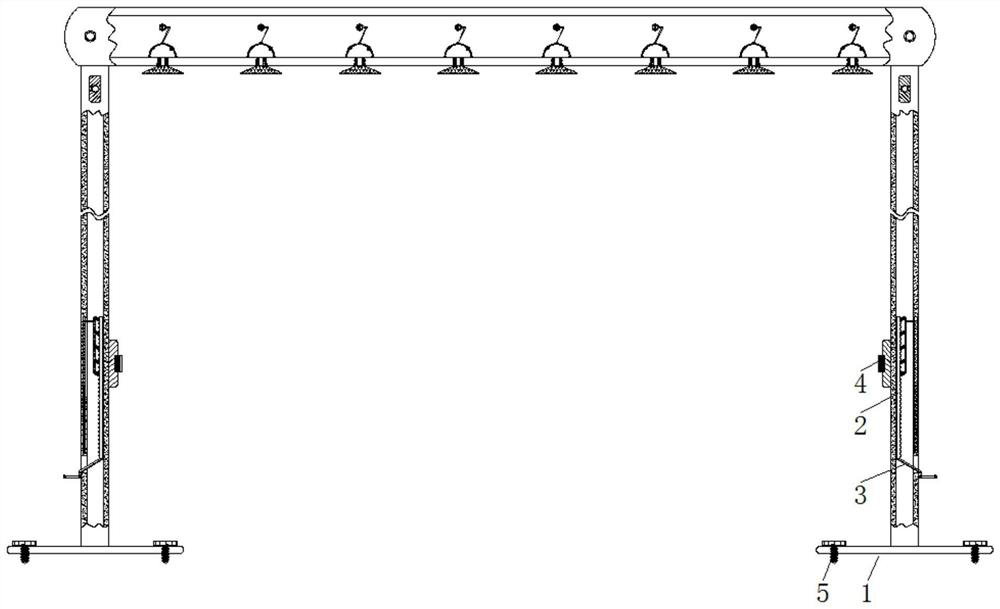

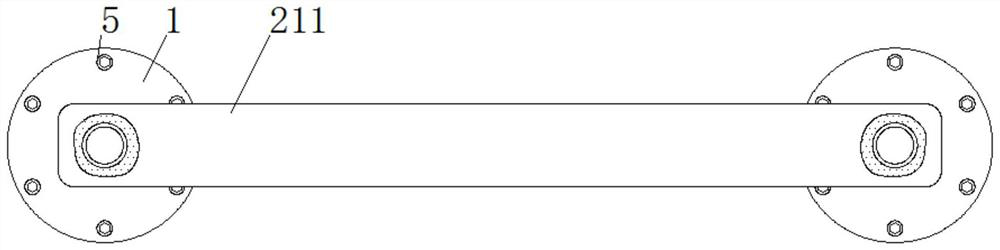

[0024] see figure 1 - Figure 5 , an adjustable environmental protection dust removal equipment for mines, including a base 1, the outside of the base 1 is movably connected with a dust removal mechanism 2, the dust removal mechanism 2 includes a recovery component 21 for slag dust collection, and a collection component 22 for dust absorption, The recovery component 21 is movably connected to the outside of the base 1 , and the collection component 22 is movably connected to the inside of the base 1 .

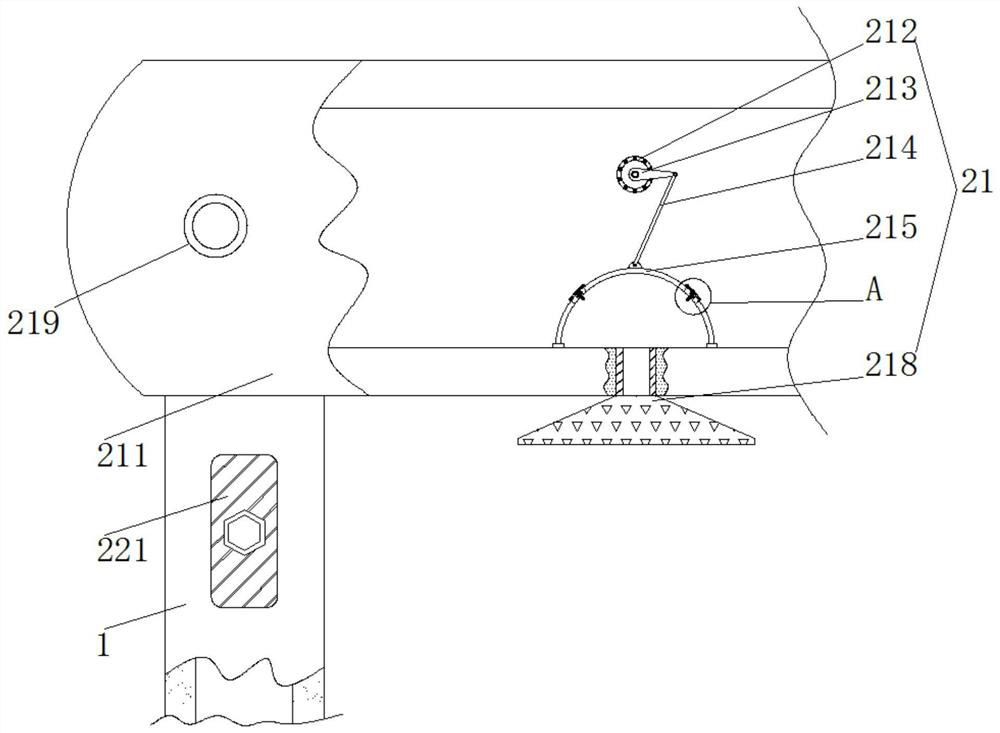

[0025] Recovery assembly 21 comprises processing chamber 211, motor 212, rotating rod 213, connecting rod 214, air pressure cover 215, exhaust port 216, elastic plate 217, one-way suction disk 218, connecting nozzle 219, and the external movable connection of base 1 has Processing chamber 211, the inside of processing chamber 211 is fixedly connected with motor 212, the outside of motor 212 is fixedly connected with rotating rod 213, the outside of rotating rod 213 is movably ...

Embodiment 2

[0029] see figure 1 , Figure 5 - Figure 6 , an adjustable environmental protection dust removal equipment for mines, including a base 1, the outside of the base 1 is movably connected with a dust removal mechanism 2, the dust removal mechanism 2 includes a recovery component 21 for slag dust collection, and a collection component 22 for dust absorption, The recovery component 21 is movably connected to the outside of the base 1 , and the collection component 22 is movably connected to the inside of the base 1 .

[0030] The inside of the base 1 is movably connected with a collection mechanism 3 for storing slag dust. The collection mechanism 3 includes an outlet 301, an accumulation plate 302, a fixed ring 303, a card slot 304, and a fastening rod 305. The surface of the base 1 is provided with an outlet 301. The inner side of the base 1 is fixedly connected with an accumulation plate 302 , and the outer side of the base 1 is fixedly connected with a fixed ring 303 . The s...

Embodiment 3

[0033] see figure 1 - Figure 6, an adjustable environmental protection dust removal equipment for mines, including a base 1, the outside of the base 1 is movably connected with a dust removal mechanism 2, the dust removal mechanism 2 includes a recovery component 21 for slag dust collection, and a collection component 22 for dust absorption, The recovery component 21 is movably connected to the outside of the base 1 , and the collection component 22 is movably connected to the inside of the base 1 .

[0034] Recovery assembly 21 comprises processing chamber 211, motor 212, rotating rod 213, connecting rod 214, air pressure cover 215, exhaust port 216, elastic plate 217, one-way suction disk 218, connecting nozzle 219, and the external movable connection of base 1 has Processing chamber 211, the inside of processing chamber 211 is fixedly connected with motor 212, the outside of motor 212 is fixedly connected with rotating rod 213, the outside of rotating rod 213 is movably c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com