Equipment and system for assembling air uniformizing cavity in tuyere and outer frame

A technology for assembling equipment and outer frames, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low production efficiency of the uniform air cavity in the tuyere and the outer frame, achieve precise assembly positioning, improve production efficiency, The effect of improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

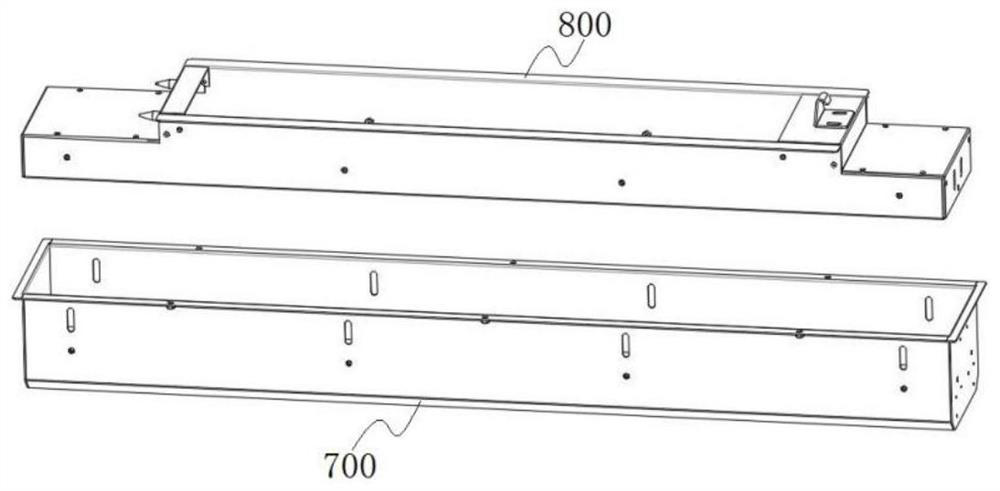

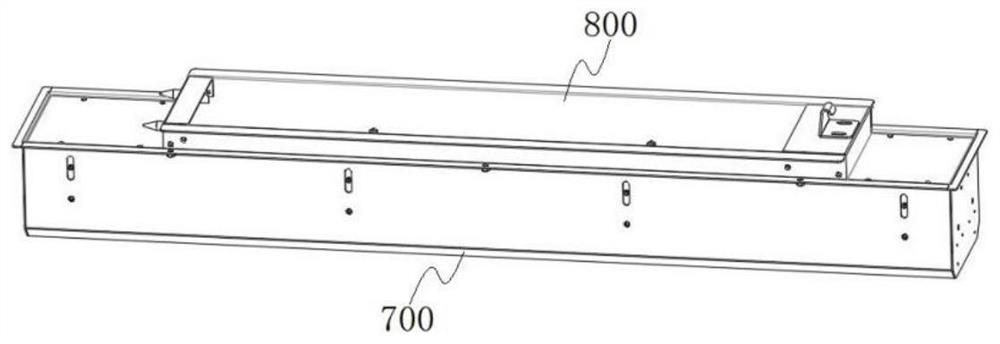

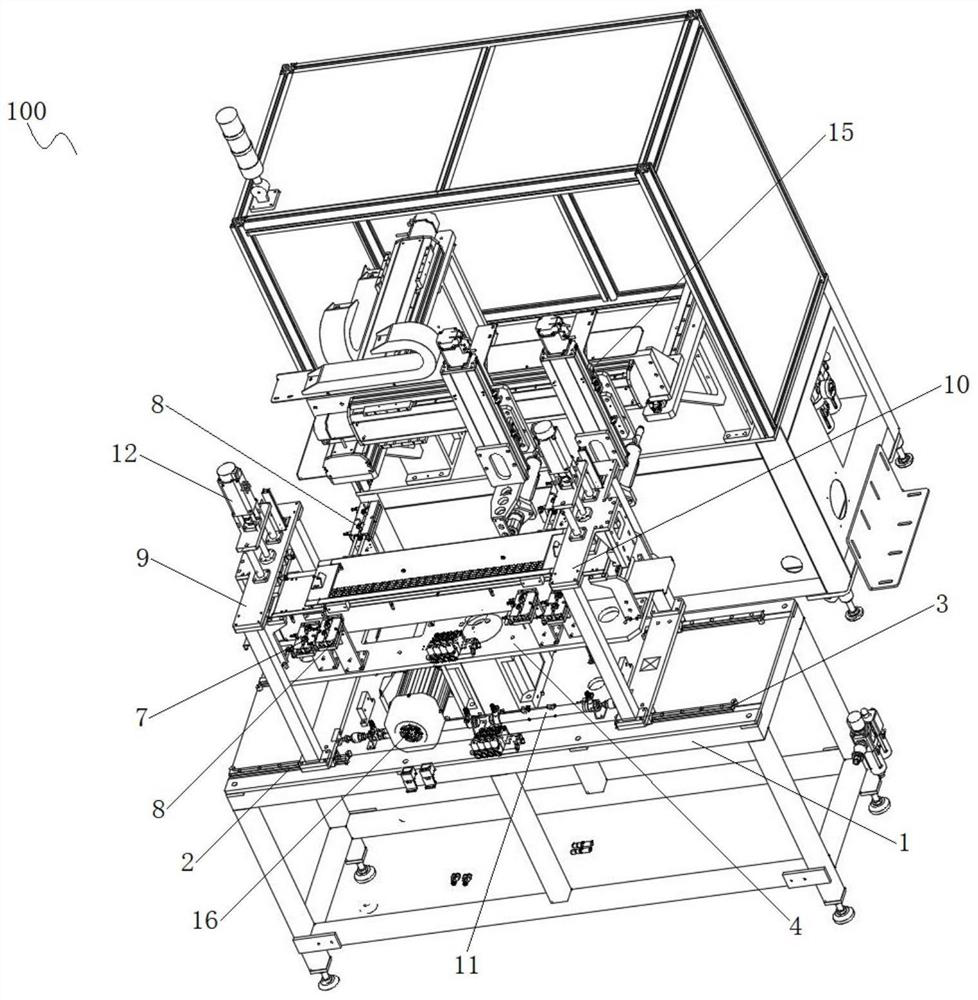

[0048] For the assembly equipment 100 of the inner air uniform chamber and the outer frame of the tuyere of the present invention, please refer to image 3 and Figure 4 As shown, the frame 1 of the device 100 has a base 19 of a working position, and an assembly platform 4 is arranged on the base 19 .

[0049] The assembly table 4 has front and rear ends in the length direction and left and right sides in the width direction. The outer frame 700 can be placed on the assembly table 4 correspondingly.

[0050] See Figure 5 and Figure 6 As shown, a first positioning component 5 and a second positioning component 6 are arranged on the assembly platform 4 . After the outer frame 700 is loaded onto the assembly platform 4, the first positioning component 5 can position the outer frame 700, specifically from the left and right sides of the outer frame 700, so as to facilitate the automatic and Accurate assembly; during assembly, the outer side of the outer frame 700 needs to fo...

Embodiment 2

[0056] This embodiment is the same as Embodiment 1. further, please see Figure 5 and Figure 6 As shown, in the device 100 for assembling the inner air uniform chamber and the outer frame of the tuyere in this embodiment, the first positioning component 5 includes a first bracket group and a second bracket group.

[0057] Wherein, the first bracket group and the second bracket group are arranged on the front end side and the rear end side of the assembly platform 4 along the length direction of the assembly platform 4; and, the first bracket group and the The second bracket group includes two brackets 51 arranged in parallel, and the two brackets 51 are specifically arranged in parallel left and right. Optionally, in the illustrated embodiment, the bracket 51 is fixedly arranged on the assembly platform 4 with a certain height. The distance between the two brackets 51 of each bracket group is adapted to the bottom of the outer frame 700 and is smaller than the distance bet...

Embodiment 3

[0060] This embodiment is the same as Embodiment 1 or Embodiment 2. further, please see Figure 5 and Figure 6 As shown, in the assembly equipment 100 of the inner air uniform chamber and the outer frame of the tuyere in this embodiment, the second positioning component 6 includes a side positioning part 61 and an end side positioning part 62 .

[0061] Wherein, the side positioning part 61 is arranged on the side of the assembly table 4, specifically, it can be arranged on the left side and / or the side of the assembly table 4; and the end side positioning part 62 is arranged on the end of the assembly table 4, specifically It may be provided on the front end and / or the rear end of the assembly table 4 . Optionally but not limited, both the side positioning member 61 and the end side positioning member 62 include an air cylinder and a positioning block driven by the air cylinder. When the side plate of the outer frame 700 is assembled on the outer frame 700, the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com