Continuous transmission side discharging device of machine tool

A discharge device and continuous technology, applied in the direction of metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of waste of human resources, high risk factor, etc., and achieve the effect of reducing excessive manual judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

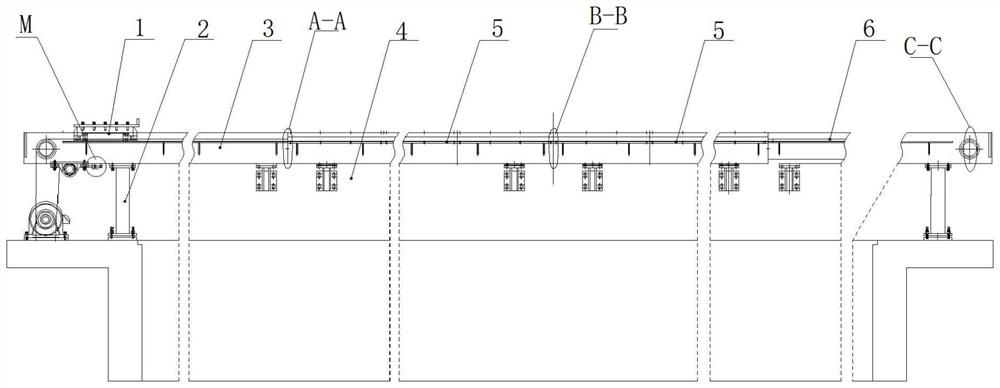

[0025] see figure 1 , the outrigger 2 is installed on the conduction plate of the side discharge device, and the underside of the outrigger 2 and the conduction plate are fixedly connected by a welding plate. When the outrigger 2 and the conduction plate are reinforced and installed, the main parts used include the inner Hexagon socket head screws, spring washers, set screws, hexagon nuts, flat washers, etc. A plurality of brackets 4 are continuously distributed on the lower side of the conduction plate. When the support 4 and the conduction plate are reinforced and installed, the main parts used include hexagon socket head cap screws, flat washers, spring washers and the like.

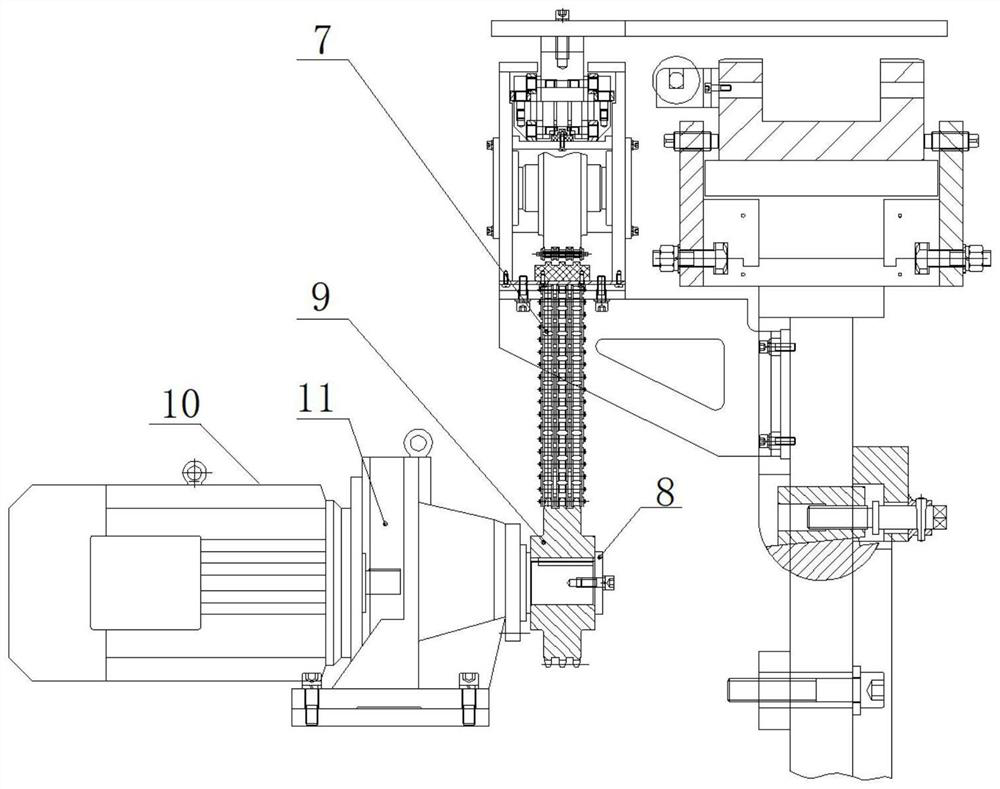

[0026] see figure 2 , the outside of the motor driving sprocket 9 is equipped with a gland 8, and the gland 8 is configured with parts such as spring washers, a plurality of hexagon socket cap screws and the like between the motor driving sprocket 9 when installing. When the cycloidal pinwheel gear...

Embodiment 2

[0033] In the present invention, the cycloidal pinwheel deceleration motor 10 drives the discharge trolley 1 to move in a directional manner. Left discharge frame 3, middle discharge frame 5, the outer position of right discharge frame 6 are all provided with discharge platform 22, when the discharge platform 22 of left discharge frame 3 positions has material [not taken off or When removing], the sensing mechanism 23 on the discharge platform 22 at the 3rd position of the left discharge frame detects that there is material on the discharge platform 22, and the discharge trolley 1 will not stay here, and the corresponding material clamping Mechanism or pushing mechanism also can not deliver the material on the discharge trolley 1 to the discharge platform 22 of left discharge rack 3 azimuths. The discharge trolley 1 will continue to move forward, looking for a subsequent discharge platform that is not occupied by materials. In this way, in the continuous discharge process, ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com