An intelligent monitoring system and method for the corrosion state of steel bars in concrete

A technology for steel corrosion and intelligent monitoring. It is applied in neural learning methods, weather resistance/light resistance/corrosion resistance, and measurement devices. It can solve problems such as difficulty in deploying conventional terminal equipment, and achieve the effect of reducing manual judgment and high recognition accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

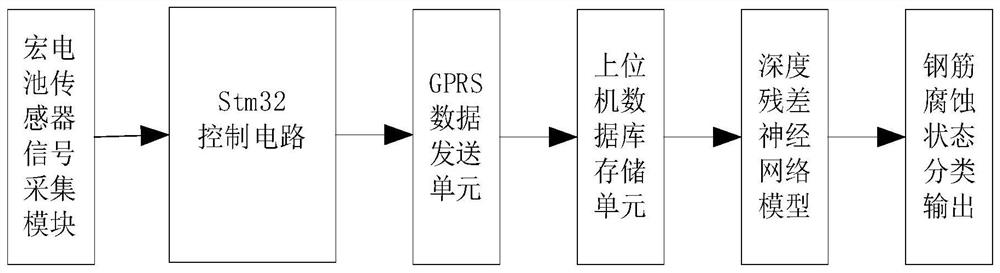

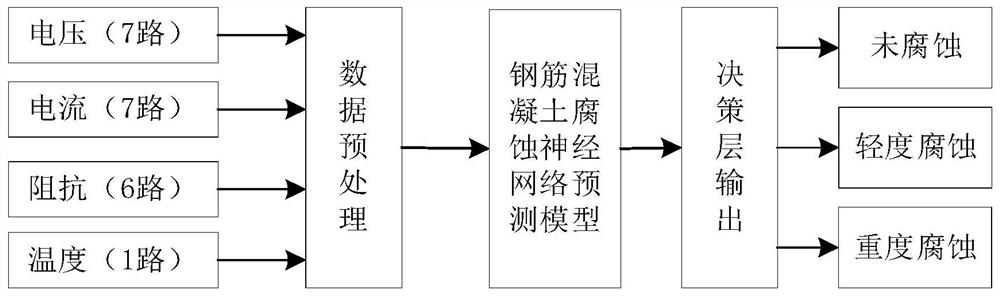

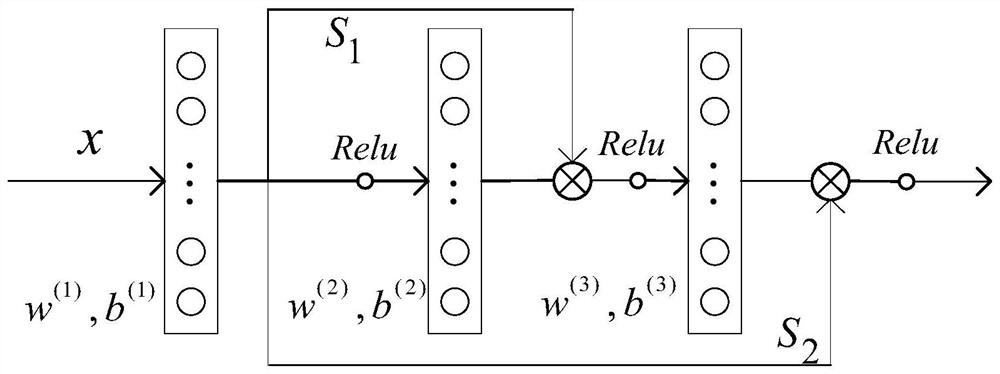

[0049] The overall functional block diagram of the intelligent monitoring system for the corrosion state of steel bars in concrete is as follows figure 1 As shown, it includes the macro battery sensor signal acquisition module, GPRS wireless data communication module, upper computer automatic classification and discrimination software, deep residual neural network algorithm model, macro battery sensor signal acquisition module to collect corrosion characteristic data, and through the GPRS wireless data communication module. The data is packaged and sent to the cloud server for storage, and the deep residual neural network algorithm model embedded in the upper computer automatic classification and discrimination software extracts the characteristic data of the database for automatic classification and discrimination of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com