Plastifying device taking plastic as raw material

A technology of raw materials and plastics, which is applied in the field of plastic refining, and can solve problems such as insufficient mixing of materials, quality problem equipment, and residual plastic residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

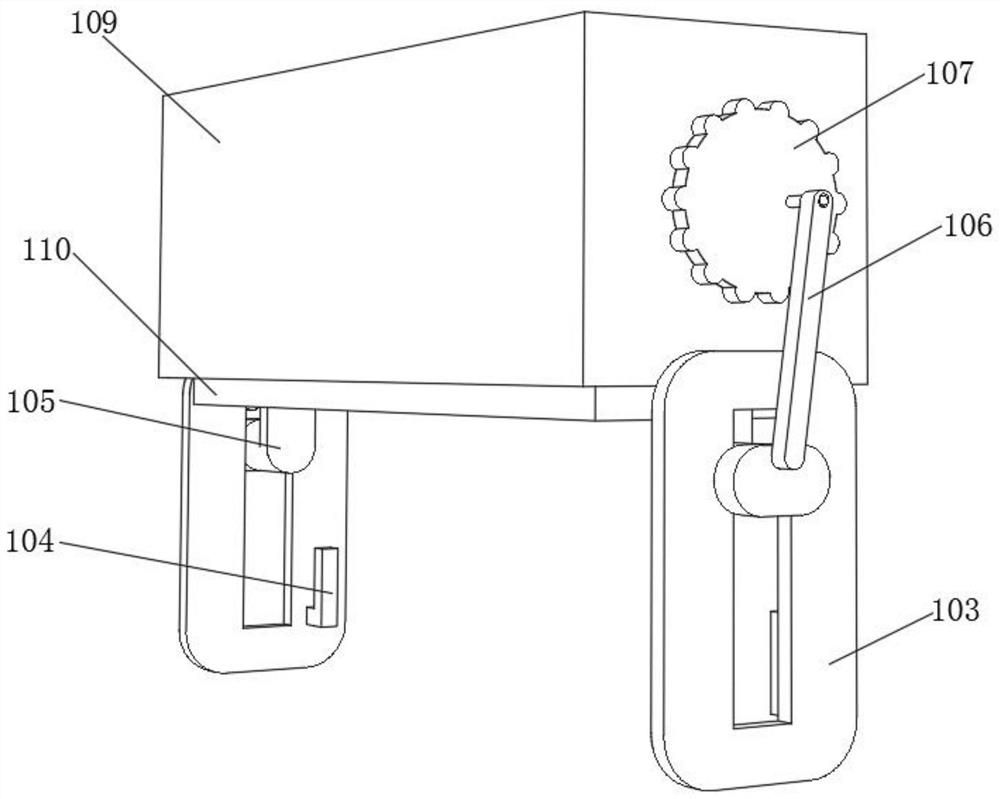

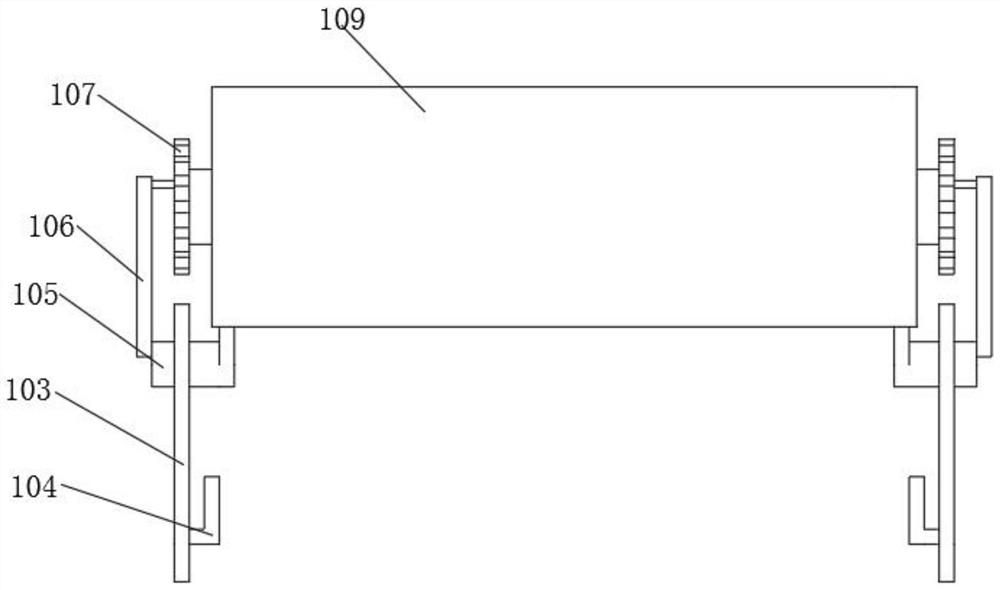

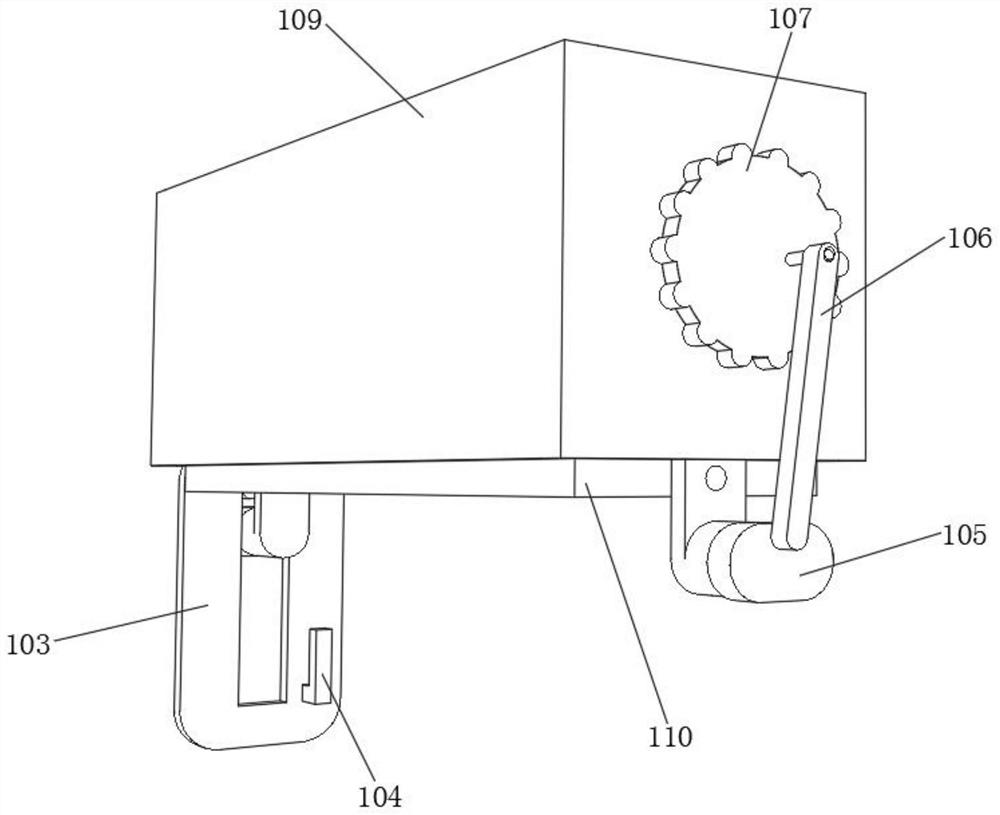

[0032] see Figure 1 to Figure 7 , a masticating device for plastic raw materials, comprising a side plate 101, the side plate 101 defines the position of the cutting device and the mixing device; the right side of the side plate 101 is fixedly connected with a connecting column 102, and the number of the connecting column 102 is Four, two as a group, each group of connecting columns 102 is respectively connected to the limit block 103, the size matches the distance between the limit block 103 and the side plate 101, and the connecting column 102 fixes the position of the limit block 103 Location;

[0033] The right side of the connecting column 102 is fixedly connected with the limit block 103, the quantity of the limit block 103 is two, and the two limit blocks 103 are axisymmetrically distributed with the shell 109 as the axis of symmetry, and the inside of the limit block 103 is provided with a through hole. The size of the through hole matches the wedge 105, and the stop...

Embodiment 2

[0039] see Figure 8 to Figure 10 , a masticating device for plastic raw materials, comprising a rear shell 301, the rear shell 301 limits the positions of a driven block 302 and a rotating block 304; the front of the rear shell 301 is provided with a driven block 302, and the number of driven blocks 302 is two A through hole is opened inside the driven block 302, and the size of the through hole matches the runner 202. The driven block 302 is squeezed and meshed with the runner 202, and starts to rotate under the drive of the runner 202, thereby driving the transmission belt 303 to start sports;

[0040] The outer side of driven block 302 is sleeved with transmission belt 303, and the quantity of transmission belt 303 is two, and the size of transmission belt 303 matches with driven block 302 and rotating block 304, and transmission belt 303 begins to move under the drive of driven block 302, thereby The rotating block 304 is started to rotate; the transmission belt 303 is s...

Embodiment 3

[0044] see Figure 1 to Figure 11 , a masticating device for plastic raw materials, comprising a side plate 101, the side plate 101 defines the position of the cutting device and the mixing device; the right side of the side plate 101 is fixedly connected with a connecting column 102, and the number of the connecting column 102 is Four, two as a group, each group of connecting columns 102 is respectively connected to the limit block 103, the size matches the distance between the limit block 103 and the side plate 101, and the connecting column 102 fixes the position of the limit block 103 Location;

[0045] The right side of the connecting column 102 is fixedly connected with the limit block 103, the quantity of the limit block 103 is two, and the two limit blocks 103 are axisymmetrically distributed with the shell 109 as the axis of symmetry, and the inside of the limit block 103 is provided with a through hole. The size of the through hole matches the wedge 105, and the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com