Blast furnace uniform air supply equipment with external flow control area and method

A technology for air supply equipment and blast furnace, applied in the direction of the tuyere, can solve the problem of uneven distribution of air volume in each tuyere of the blast furnace, and achieve the effect of improving the uniformity of air volume distribution, simple structure and obvious changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

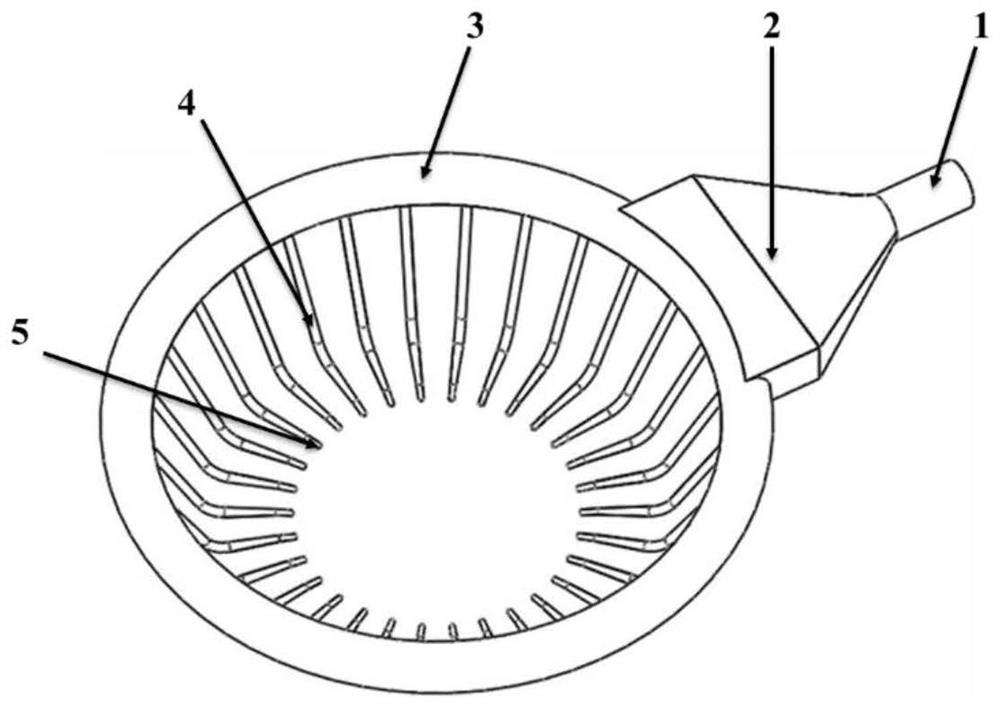

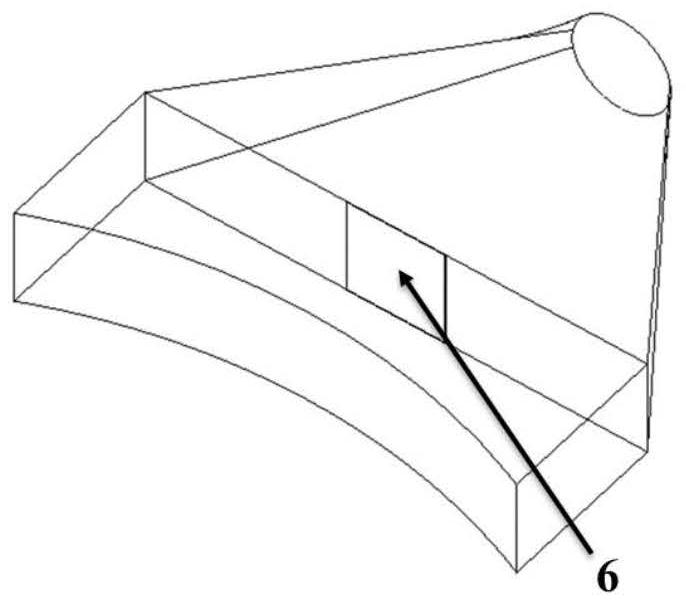

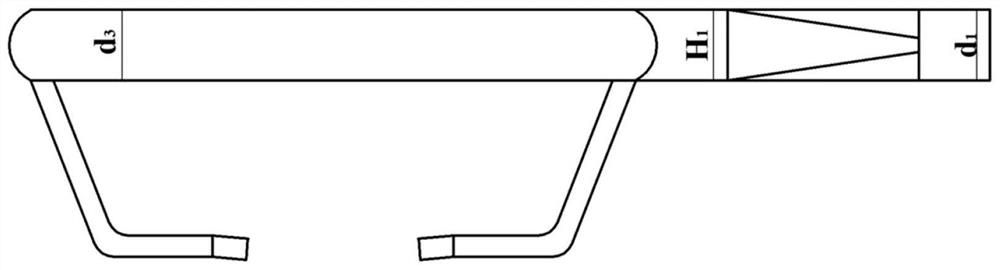

[0059] Blast furnace uniform air supply equipment with external flow control area, the structure diagram is as follows figure 1 As shown, the left view is as image 3 As shown, the left view of the hot air branch pipe and the air outlet is as follows Image 6 As shown, the structure diagram of the external flow control area of the equipment is as follows figure 2 As shown, the top view of the external flow control area is as follows Figure 4 As shown, the structure of the baffle in the external flow control area Figure 5 shown. Including hot air main pipe 1, hot air surrounding pipe 3, hot air branch pipe 4, tuyere 5 and external flow control area 2. The front and rear ends of the external flow control area 2 are respectively connected with the main hot air pipe 1 and the hot air surrounding pipe 3 , and the hot air branch pipes 4 are evenly arranged along the circumference of the hot air surrounding pipe 3 , and the hot air is sent into the furnace through the tuyere...

Embodiment 2

[0081] The same as Example 1, the difference is that the expansion angle of the expansion section in the external flow control area is 80°. After the equipment runs smoothly, the standard deviation of the air volume is calculated to be 0.62. After testing, the flow velocity of the hot air after passing through the baffle is 8m / s.

Embodiment 3

[0083] Same as Example 1, the difference is that the hot air volume is increased to 4800Nm 3 / min, after the equipment runs smoothly, the standard deviation of the air volume is calculated to be 0.65. After testing, the flow rate of the hot air after passing through the baffle is 8m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com