Grinding machine for food detection pretreatment

A food inspection and grinding machine technology, applied in grain processing, preparation of test samples, etc., can solve the problems of food accumulation on the top of the blanking plate, affecting the efficiency of food blanking, and food adhering to the outer wall of the grinding roller, etc. To achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

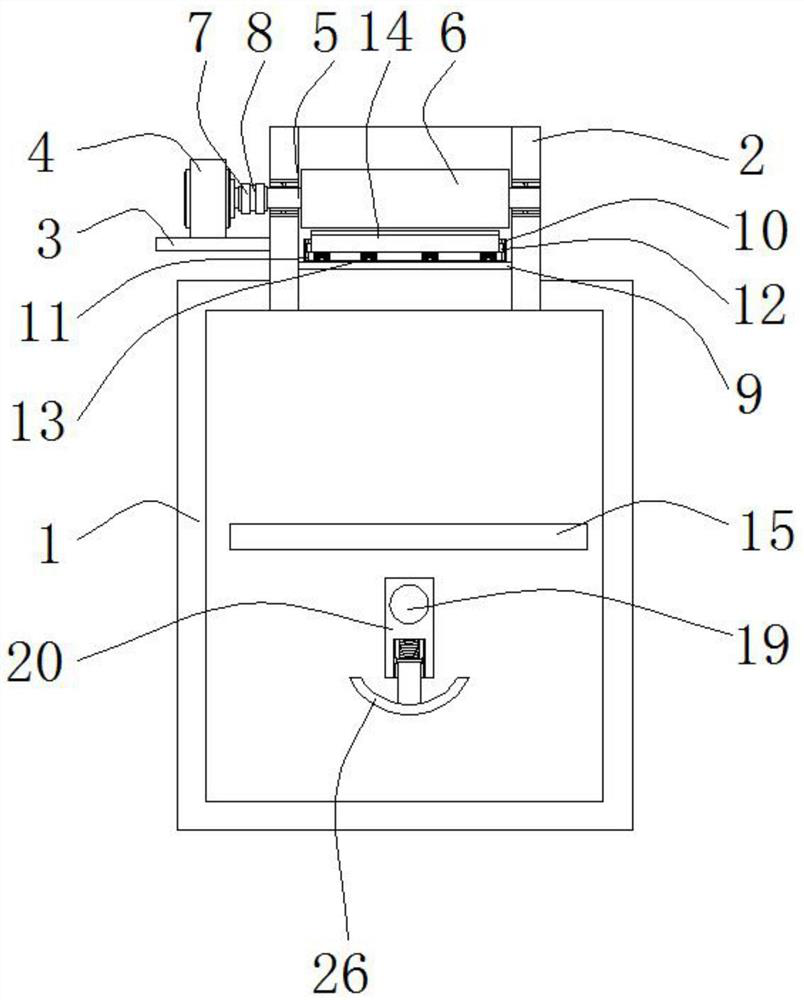

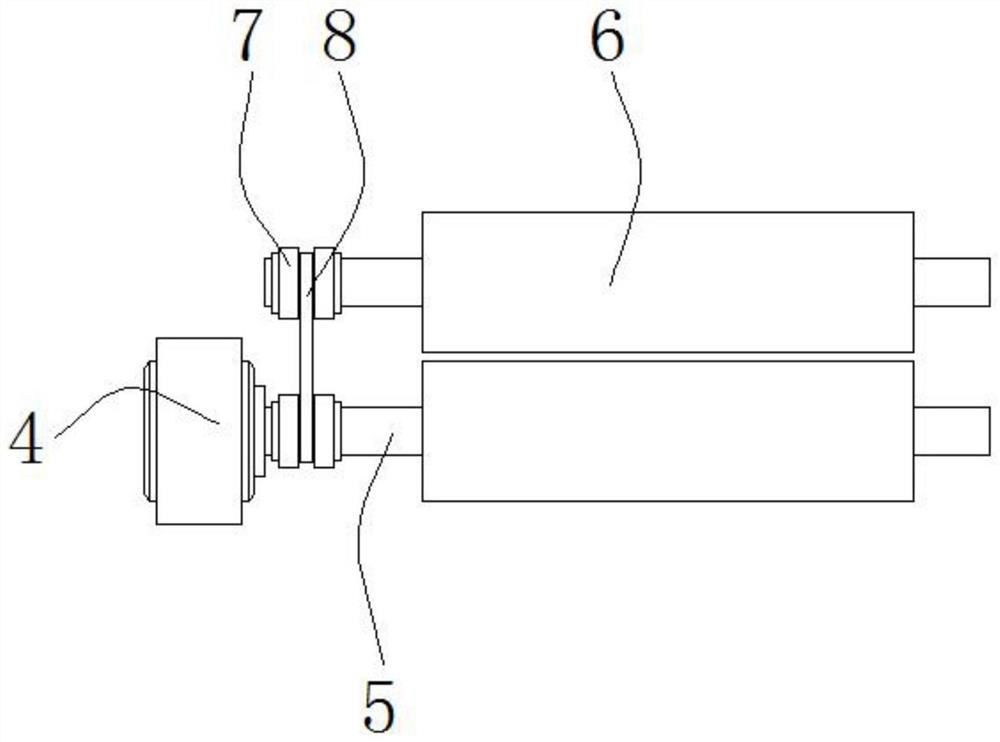

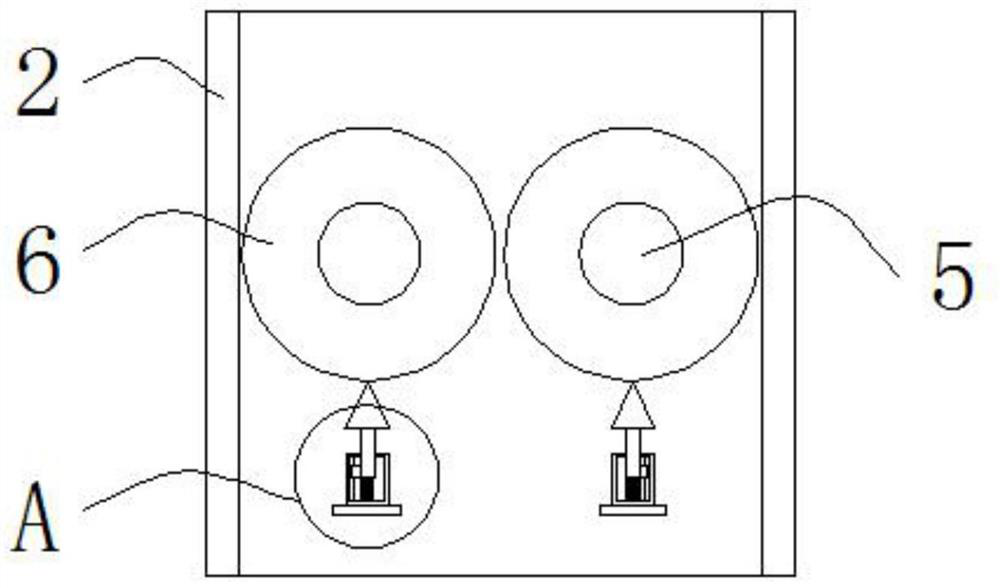

[0026] Embodiment 2: The side wall on one side of the device box 1 is provided with a through hole 16, the side wall on one side of the device box 1 is equipped with a tapered scraper 15 that runs through the through hole 16, and the side wall at one end of the device box 1 is equipped with a box 17, and the inside of the installation box 17 is equipped with a second motor 18, the output end of the second motor 18 is installed with a second rotating shaft 19 that runs through the inside of the device box 1 through a coupling, and the outer walls of the second rotating shaft 19 are all installed with limited Position rod 20, the bottom end of limit rod 20 is provided with groove 21, and the sidewall of two ends inside groove 21 is equipped with second slide rail 22, and the inside of second slide rail 22 is provided with second slide block 23, and An end of the second slide block 23 away from the second slide rail 22 is equipped with a connecting plate 24, the bottom end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com