Dry type granulator whole grain screen support capable of adjusting angle of feeding end

A dry granulator and feed end technology, which is applied in the methods of granulating raw materials, sieves, chemical instruments and methods, etc., can solve the problem that the gap between the screen and the granulating knife cannot be changed, the granulating ability is insufficient, and the material is easy to Clogging and other problems, to avoid excessive swing speed, improve particle size, and avoid easy clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

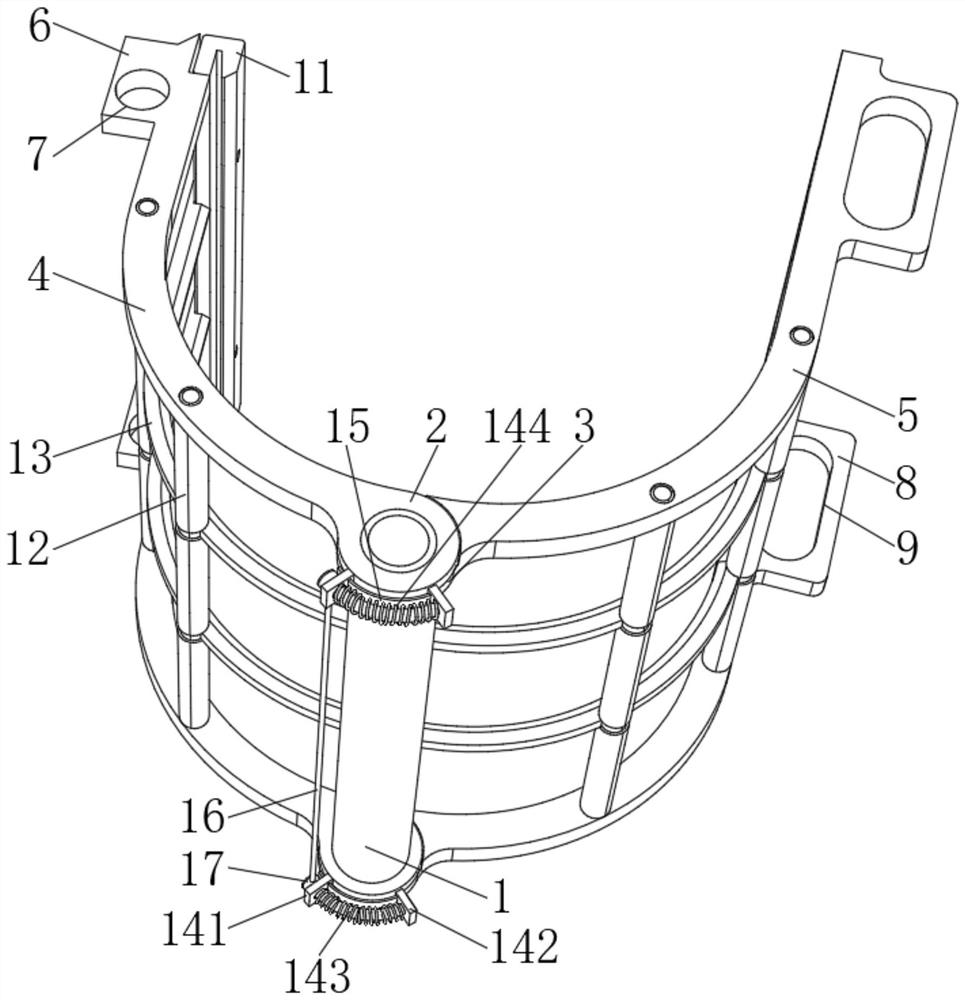

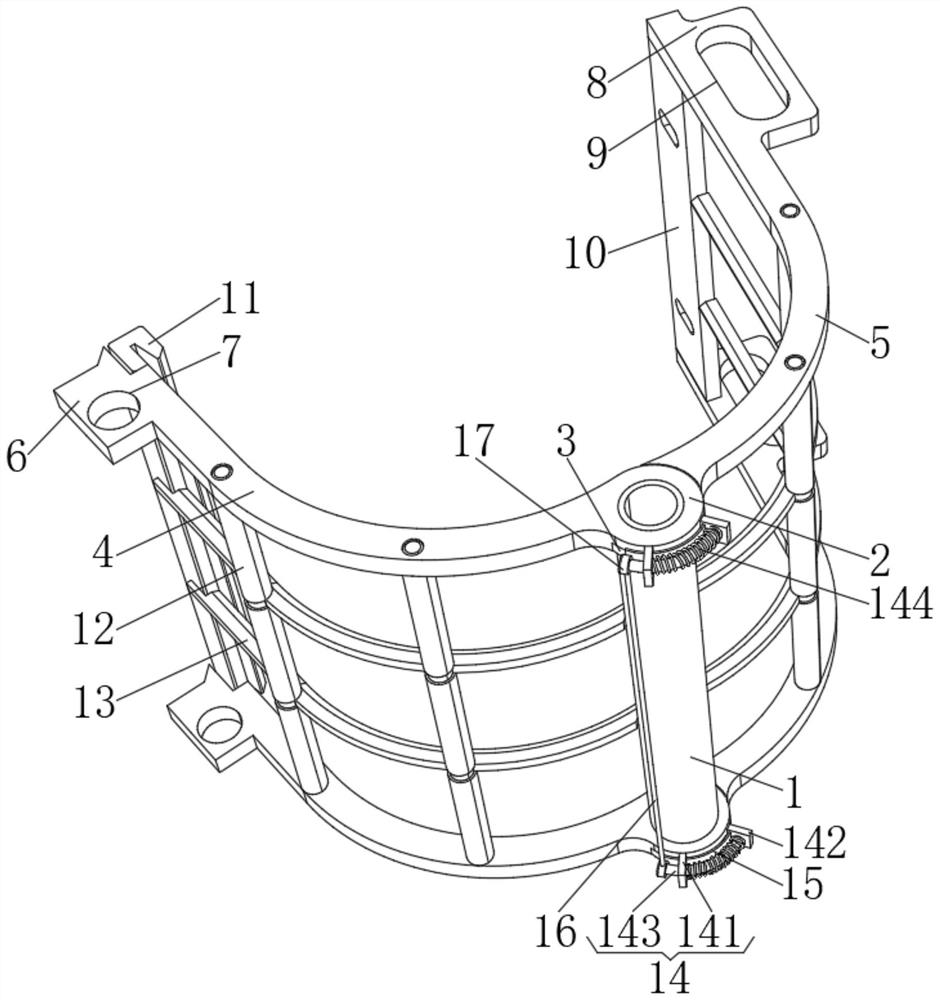

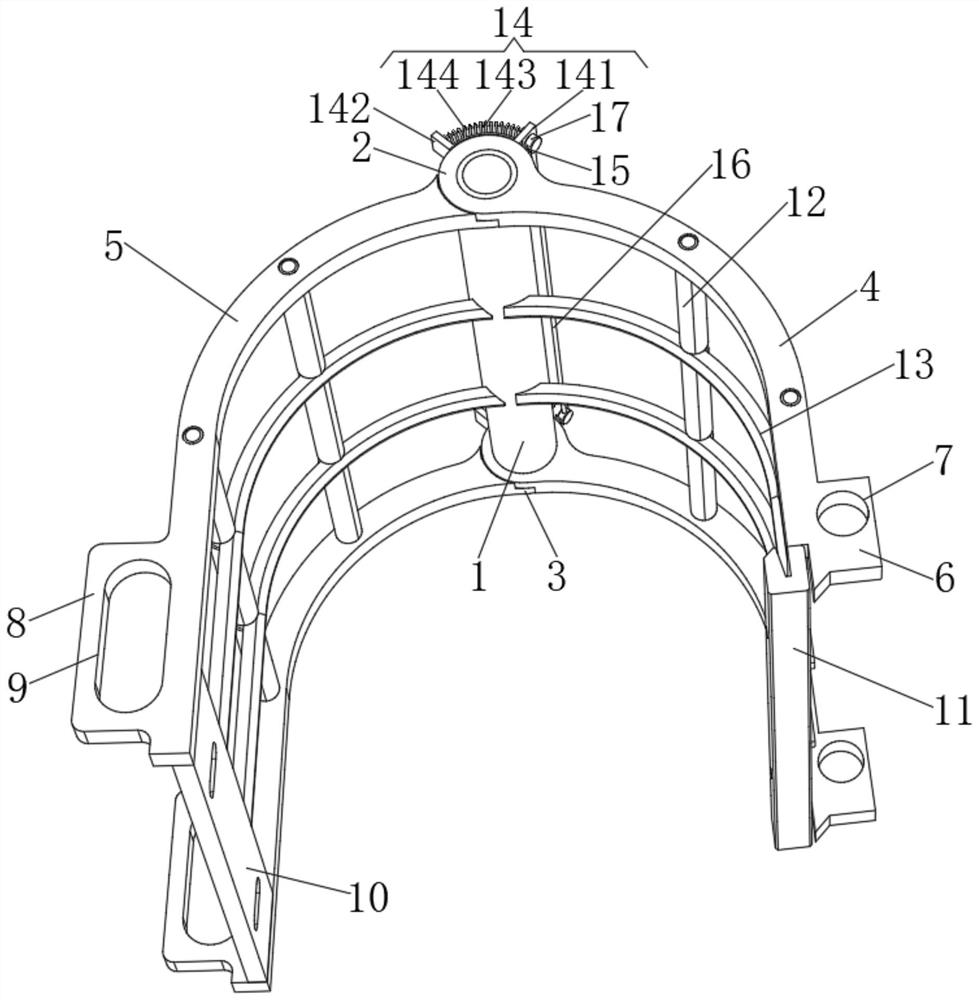

[0026] see Figure 1-6 , the present invention provides a technical solution: a dry granulator sizing screen support with adjustable feeding end angle, including a fixed shaft 1, the top and bottom of the fixed shaft 1 are fixedly connected with a hollow shaft, and the hollow shaft The first rotary sleeve 2 is rotatably connected to the top, and the side of the first rotary sleeve 2 close to each other is movably connected to the second rotary sleeve 3 and the inner ring of the second rotary sleeve 3 is rotatably connected to the surface of the hollow shaft. The second rotary sleeve 3 The sides close to each other are movably connected with the top and bottom of the fixed shaft 1, the left side of the first rotary sleeve 2 is integrally formed with a first arc-shaped plate 4, and the right side of the second rotary sleeve 3 is integrally formed with a second arc-shaped plate 5. Both the first rotary sleeve 2 and the second rotary sleeve 3 are provided with an auxiliary mechani...

Embodiment 2

[0028] see Figure 1-6, the present invention provides a technical solution: a dry granulator sizing screen support with adjustable feeding end angle, including a fixed shaft 1, the top and bottom of the fixed shaft 1 are fixedly connected with a hollow shaft, and the hollow shaft The first rotary sleeve 2 is rotatably connected to the top, and the side of the first rotary sleeve 2 close to each other is movably connected to the second rotary sleeve 3 and the inner ring of the second rotary sleeve 3 is rotatably connected to the surface of the hollow shaft. The second rotary sleeve 3 The sides close to each other are movably connected with the top and bottom of the fixed shaft 1, the left side of the first rotating sleeve 2 is integrally formed with a first arc-shaped plate 4, and the back of the left side of the first arc-shaped plate 4 is integrally formed with an expansion plate 6 , the expansion plate 6 is provided with a fixing hole 7, the design of the expansion plate 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com