Molten metal splashing prevention cooling protection equipment for casting mold opening of large casting

A large-scale casting and protective equipment technology, applied in the field of metal casting, can solve the problems of molten steel splashing to the top of the mold, solidification mold use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

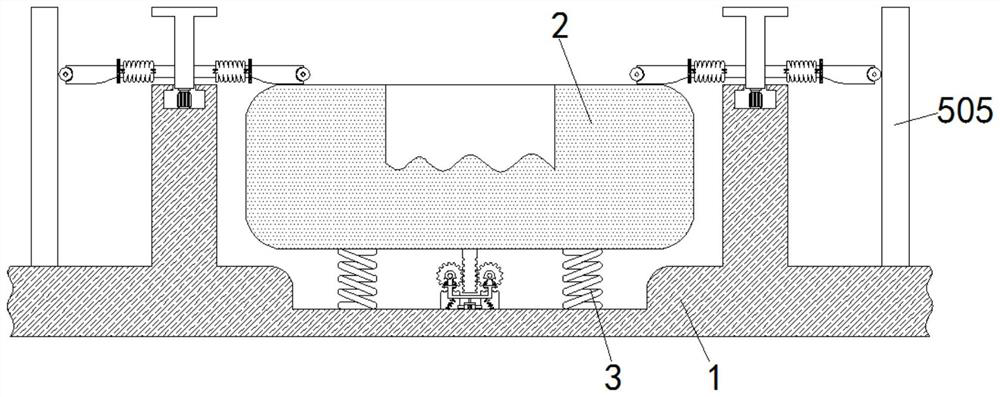

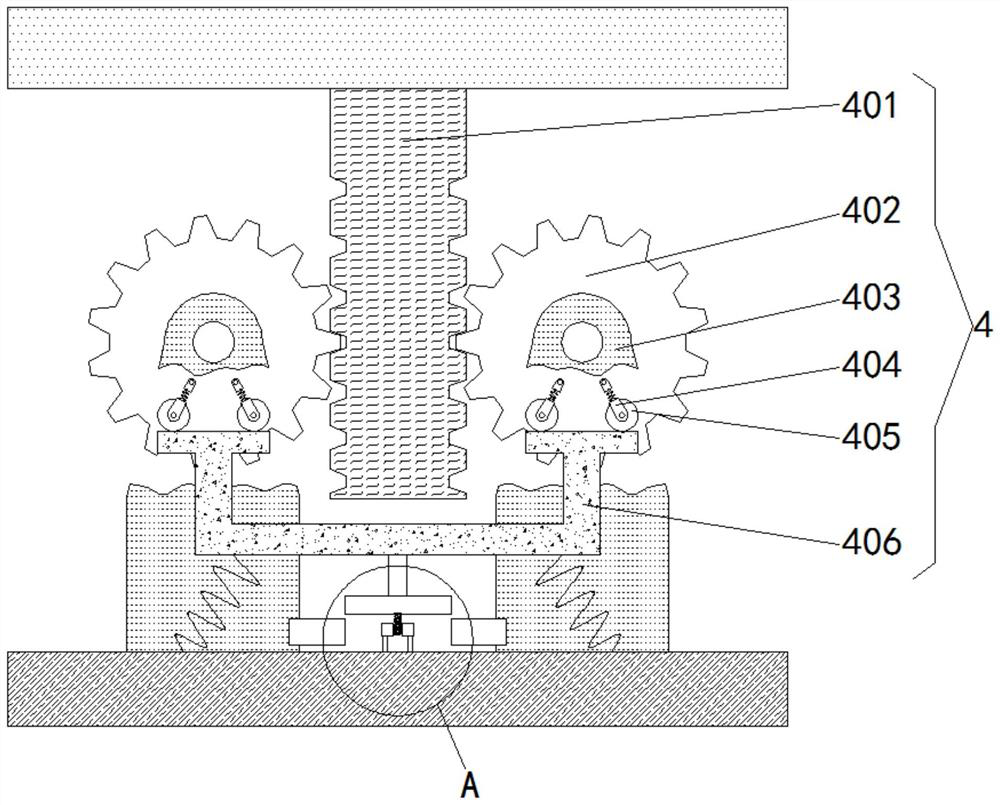

[0024] Example 1: Please refer to Figure 1-4 , a cooling protection device for large-scale casting casting molds, including a base 1, the top of the base 1 is fixedly connected with a buffer spring 3, and the top of the buffer spring 3 is fixedly connected with a mold 2, the mold 2 A detection and processing mechanism 4 is arranged below the detection and processing mechanism 4. A linkage gear 401 is fixedly installed inside the detection and processing mechanism 4. The side of the linkage gear 401 is meshed with a linkage gear 402, and the surface of the linkage gear 402 is rotatably connected with a fixed plate. 403, the surface of the interlocking gear 402 is slidingly connected with an extruding ball 405, and the side of the extruding ball 405 is rotatably connected with a stretching rod 404, and the inside of the stretching rod 404 is provided with a stretching spring, and the other side is connected with the interlocking gear. The surface of 402 is connected. When the i...

Embodiment 2

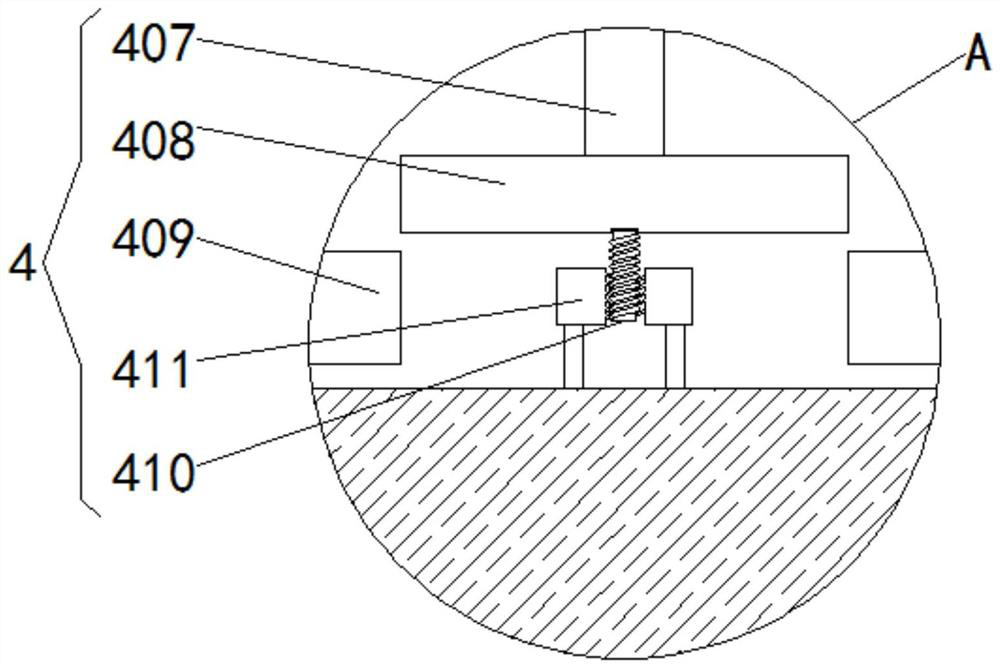

[0026] Example 2: Please refer to Figure 1-4 , a cooling protection device for large-scale casting casting molds, including a base 1, the top of the base 1 is fixedly connected with a buffer spring 3, and the top of the buffer spring 3 is fixedly connected with a mold 2, the mold 2 A detection and processing mechanism 4 is arranged below the detection and processing mechanism 4. A linkage gear 401 is fixedly installed inside the detection and processing mechanism 4. The side of the linkage gear 401 is meshed with a linkage gear 402, and the surface of the linkage gear 402 is rotatably connected with a fixed plate. 403, the surface of the interlocking gear 402 is slidingly connected with an extruding ball 405, the side of the extruding ball 405 is connected with a stretching rod 404, the bottom of the extruding ball 405 is provided with a support frame 406, and the bottom of the support frame 406 is fixedly connected with An insulating rod 407, the bottom of the insulating rod...

Embodiment 3

[0028] Example 3: Please refer to Figure 1-4 , a cooling protection device for large-scale casting casting molds, including a base 1, the top of the base 1 is fixedly connected with a buffer spring 3, and the top of the buffer spring 3 is fixedly connected with a mold 2, the mold 2 A detection and processing mechanism 4 is arranged below the detection and processing mechanism 4. A linkage gear 401 is fixedly installed inside the detection and processing mechanism 4. The side of the linkage gear 401 is meshed with a linkage gear 402, and the surface of the linkage gear 402 is rotatably connected with a fixed plate. 403, the surface of the interlocking gear 402 is slidingly connected with an extruding ball 405, and the side of the extruding ball 405 is rotatably connected with a stretching rod 404, and the inside of the stretching rod 404 is provided with a stretching spring, and the other side is connected with the interlocking gear. The surface of 402 is connected. When the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com