Self-adaptive rib plate weld joint continuous welding equipment

A self-adaptive, rib-plate technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of manual operation, unified H-beam welding quality specifications, and low H-beam processing and production efficiency. Improve welding quality, increase the range of motion, and achieve the effect of clamping limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

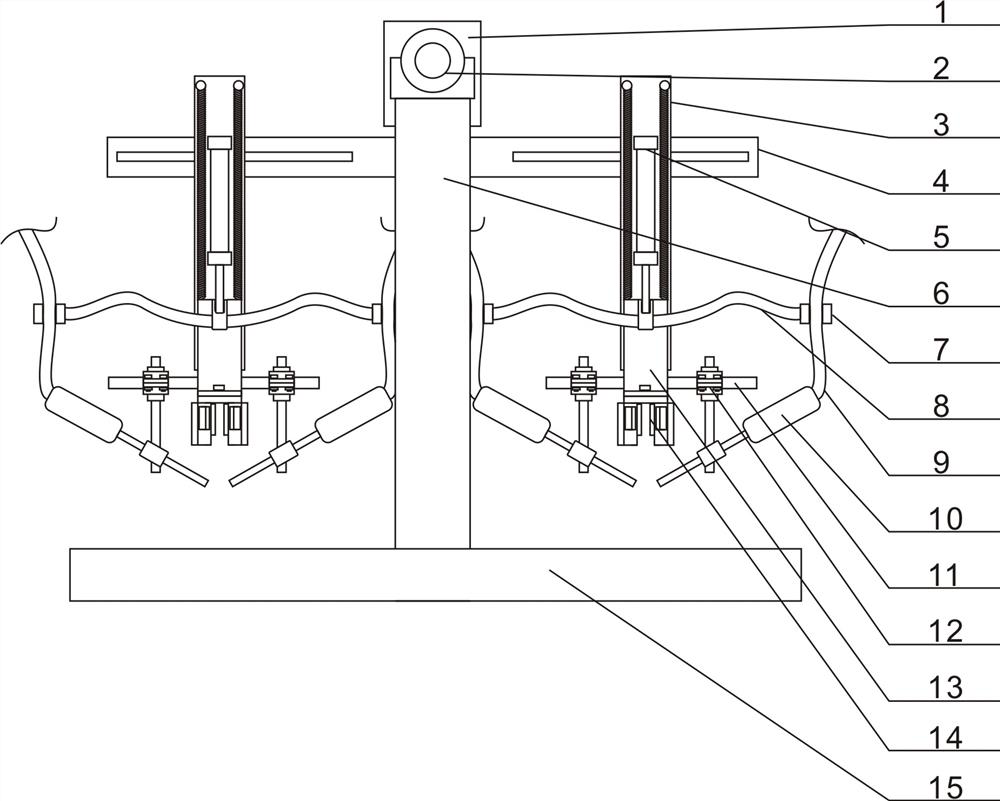

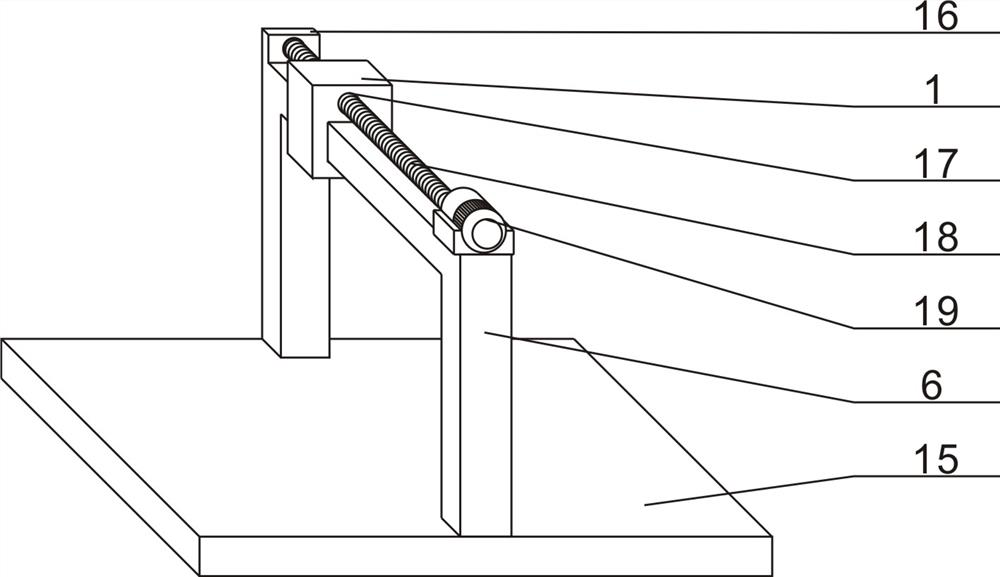

[0038] Embodiment 1, a continuous welding equipment for self-adaptive stiffened plate welds, including a bottom plate 15 and a portal frame 6. The sliding block 1 at the bottom, and the drive mechanism 2 that drives the sliding block 1 to move axially along the mandrel, specifically, the sliding block 1 is provided with a port that matches the mandrel of the portal frame 6, and the sliding block 1 passes through the The mouth sleeve is arranged on the ejector rod body, and is slidably adjusted by the driving mechanism 2. The driving mechanism 2 includes a motor 19, a baffle plate 16 and a screw rod 18. One end of the upper surface of the ejector rod body of the portal frame 6 is provided with a motor 19, and the other end is provided with a motor 19. Baffle plate 16 is arranged, and the passage upper side of sliding block 1 is provided with screw hole 17, and the output end of motor 19 is fixedly connected with the screw rod 18 that matches with screw hole 17, and the other end...

Embodiment 2

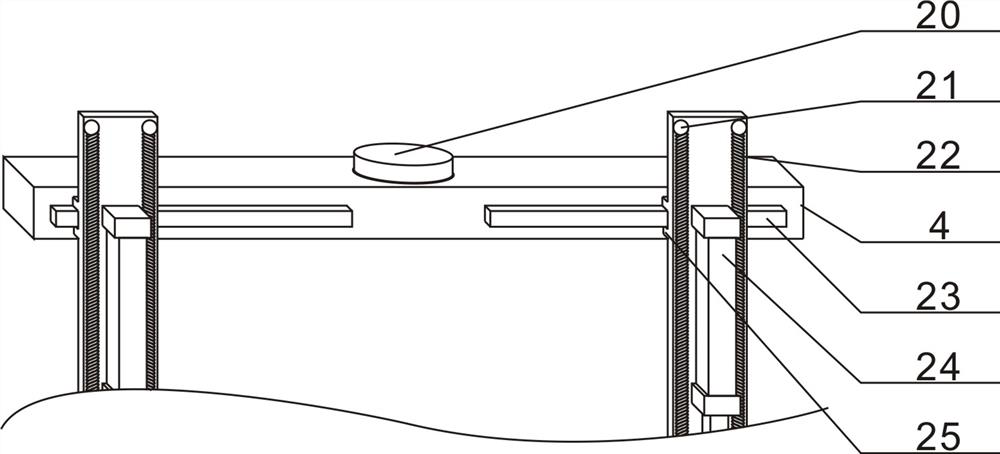

[0043] Embodiment 2, in order to reduce the moving distance of the welding frame and improve the welding quality during the continuous welding operation of the non-linear weld seam, the middle part of the upper surface of the pole 4 is provided with a rotating shaft 20, and the pole 4 is connected with the rotating shaft 20 The lower surface of the sliding block 1 is rotationally connected, and the rotational connection between the support rod and the sliding block is realized through the rotating shaft, so that the support rod can be properly rotated with the walking guidance of the guide mechanism when performing continuous welding operations on the arc-shaped ribs. Thereby ensuring the stability and high efficiency of arc continuous welding.

Embodiment 3

[0044] Embodiment 3, in the process of continuous welding operation, after the welding is completed, the guide mechanism 14 and the welding torch 10 must be de-stressed from the weld seam to realize the complete welding operation of the weld seam. However, in order to ensure the welding quality, it is often necessary to The welding seam position has been repeatedly welded, but the guiding mechanism 14 and the welding torch 10 have been separated from the welding seam position. In addition, in order to ensure the welding quality, the welding torch 10 is often on the rear side of the guiding mechanism 14. If the secondary welding operation is performed, Then it is necessary to reset the guide mechanism 14 and the welding torch 10 first, and then perform the positioning adjustment again before performing the secondary welding operation, which is very cumbersome to operate and affects the progress of the welding operation. In order to realize that the welding seam position can be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com