Integrated cast-embedded connecting pipe and shell and preparation process thereof

A preparation process and a technology for connecting pipes, which are applied in the field of portable mid-mounted motor casings, can solve the problems affecting the life safety of cyclists, the joints are easily broken and deformed, and achieve the design and control of die-casting process parameters, The effect of increasing the bearing area and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

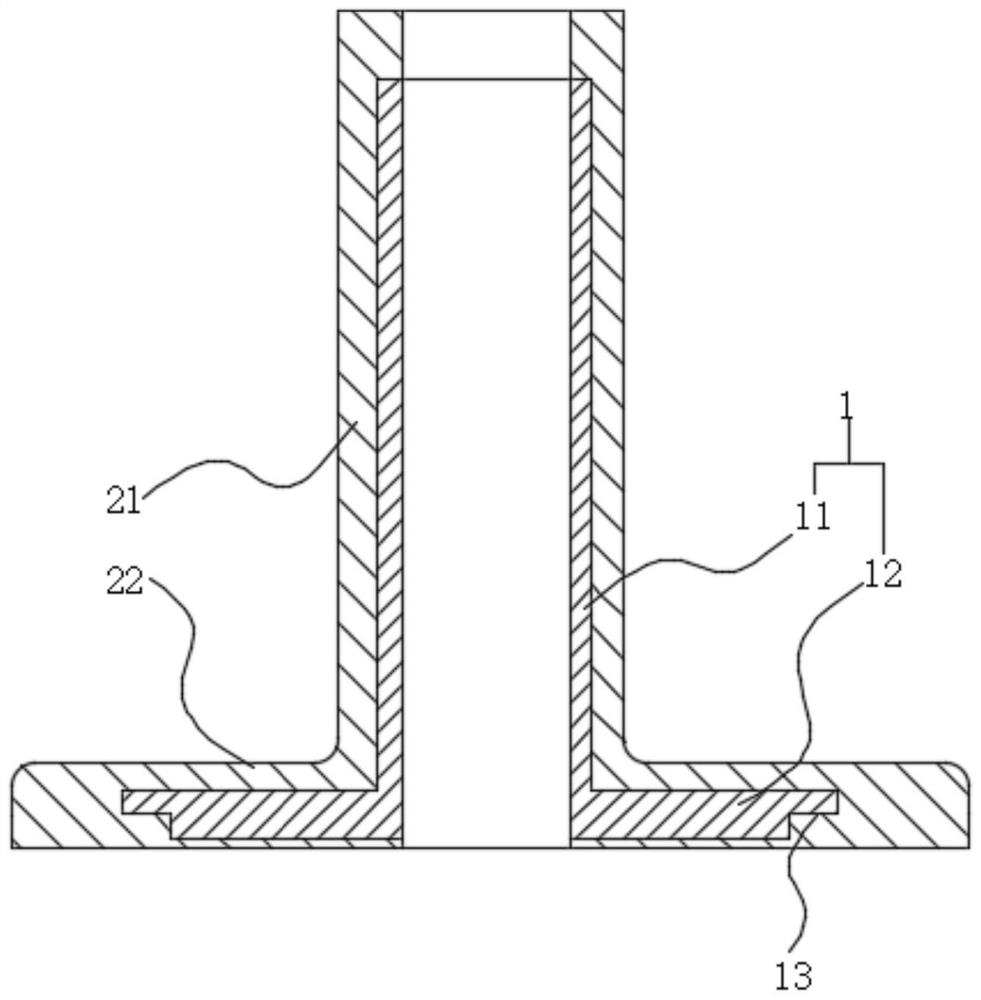

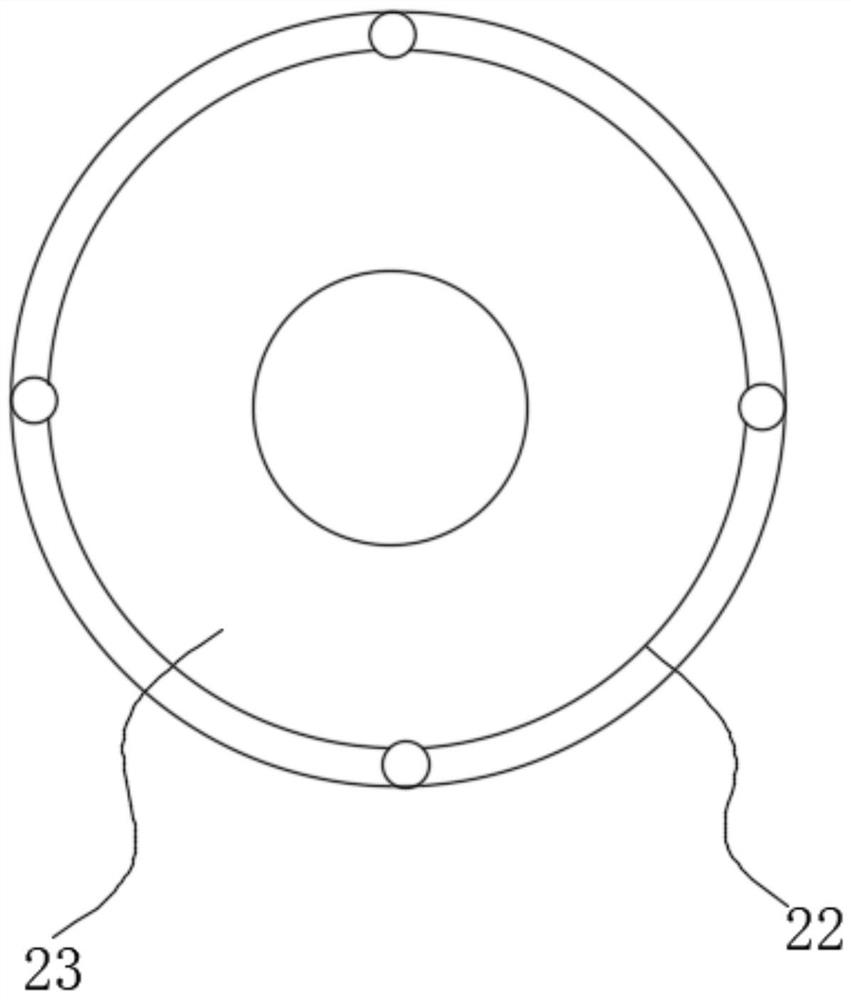

[0035] A one-piece cast-embedded connecting pipe and housing, such as figure 1 As shown, it includes an integrally formed casting insert 1, the casting insert 1 is a connecting pipe 11 and an anti-rotation structural member 12 located at the end of the connecting pipe 11, wherein the outer wall of the connecting pipe 11 is wrapped with a first outer shell 21, and The exterior of the transition member 12 is wrapped with a second outer casing 22 , the second outer casing 22 and the first outer casing 21 are integrally formed by die-casting and seamlessly bonded to the casting insert 1 . Therefore, this solution realizes the seamless combination of two different material components, and ensures the overall The components will not be bent and deformed under long-term and high-load operating conditions, which ensures the life of the motor and the stability of its operation. In this embodiment of the present invention, the casting insert 1 is an iron stamping part, and the first ou...

Embodiment 2

[0040] A preparation process for an integrated cast-embedded connecting pipe and shell, such as figure 1 and figure 2 shown, including the following steps:

[0041] S1. Casting insert 1 is obtained by perforating, annealing, cold / hot rolling, sawing, turning, stamping, and other processes of steel or iron with high hardness and high strength;

[0042] S2. When designing the casting mold, the position of the casting insert 1 is reserved inside the mold, and the positioning point or positioning groove of the casting insert 1 is set inside the mold to prevent the casting insert 1 from moving inside the mold;

[0043] S3. The casting insert 1 is fixed in the second mold through the preset positioning point or positioning groove after cooling, demolding and pickling, and after the mold is closed, the aluminum water with low cost and light weight is poured quantitatively into the barrel of the die-casting machine Then fill it between the second mold and the casting insert 1 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com