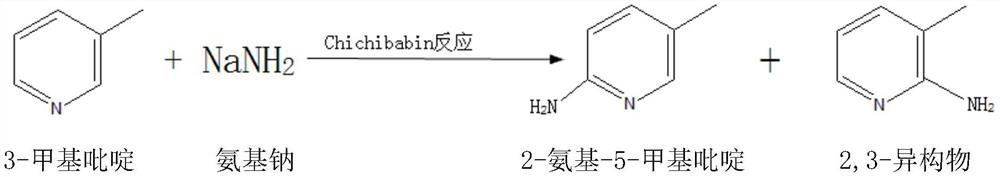

Preparation method of 2-amino-5-methylpyridine

A technology of picoline and amino, which is applied in the field of preparation of 2-amino-5-picoline, can solve the problems of high pressure in the treatment of three wastes, many reaction steps, and difficulty in realizing industrial production, and achieve less three wastes and fewer reaction steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

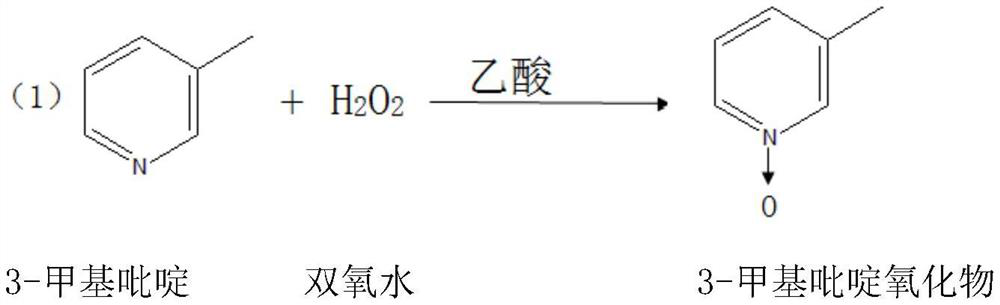

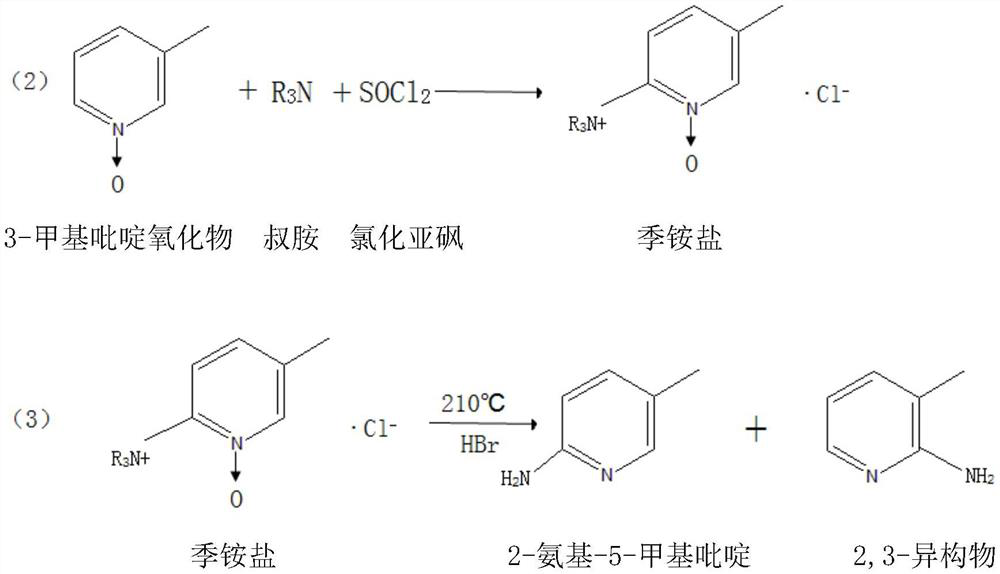

Method used

Image

Examples

Embodiment 1

[0047] Add 800mL N, N-dimethylaniline, 93.6g (2.4mol) NaNH 2 , 7.0 g 2-amino-5-picoline. N 2 After replacing the air in the kettle twice, stir and heat up to 143°C, N 2 The pressure is 32kg / cm 2 .

[0048] 186.3g (2.0mol) of 3-methylpyridine was evenly pressed into the kettle for reaction within 5 hours with a pressurized metering pump, and the reaction temperature was controlled at 147-151°C. As the reaction progresses, the pressure in the kettle rises slowly, generally at 70kg / cm 2 the following. If the internal pressure exceeds 70kg / cm 2 , the vent valve can be slightly opened to keep the internal pressure at 70kg / cm 2 the following.

[0049] After adding 3-picoline, then at 147~151℃, pressure 66-70kg / cm 2Under reaction 5hr. Then cool down to below 35°C, vent the residual gas in the kettle, and use N 2 Substitution twice to remove the generated H 2 .

[0050] Remain 45g of reaction liquid in 2 liters of stainless steel pressure reactors, transfer the rest of th...

Embodiment 2

[0055] In 2 liters of stainless steel pressurized reactors, add the 45g reaction solution before hydrolysis reserved in the reserved examples, 800mLN, N-dimethylaniline, 93.6g (2.4mol) NaNH 2 . N 2 Warm up to 145°C after replacement, N 2 The pressure is 32kg / cm 2 . 186.3g (2.0mol) of 3-methylpyridine was evenly pressed into the kettle for reaction within 5 hours with a pressurized metering pump, and the reaction temperature was controlled at 147-151°C. As the reaction progresses, the pressure in the kettle rises slowly, generally at 70kg / cm 2 the following. If the internal pressure exceeds 70kg / cm 2 , the vent valve can be slightly opened to keep the internal pressure at 70kg / cm 2 the following.

[0056] After adding 3-picoline, then at 147~151℃, pressure 66-70kg / cm 2 Under reaction 5hr. Then cool down to below 35°C, vent the residual gas in the kettle, and use N 2 Substitution twice to remove the generated H 2 .

[0057] In 2 liters of stainless steel pressure re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com