Textile machine for producing air purification fabric

A technology for air purification and textile machines, which is applied in textiles and papermaking, fabric surface trimming, heating/cooling fabrics, etc. It can solve the problems of fiber line restoration, air cannot be effectively purified, and thread loosening is not thorough, etc., to expand air circulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

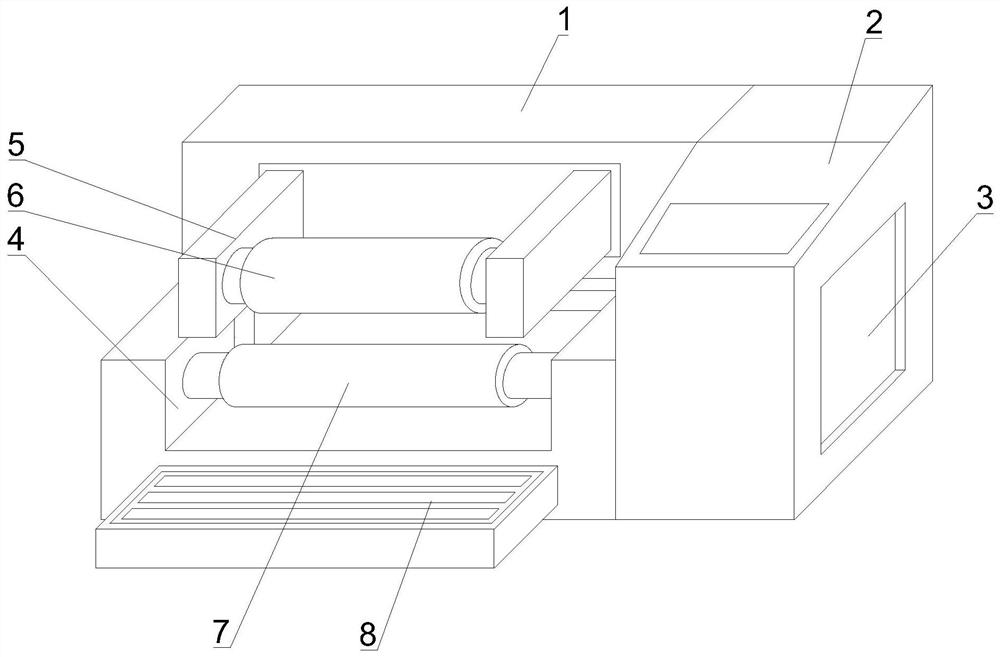

[0037] Such as Figure 1-6 As shown, the present invention provides a kind of textile machine for producing air-purifying fabrics, comprising an air-purifying fabric spinning machine 1, a processing platform 4, an extension processing arm 5, a rotating shaft cylinder 6 and a heated plastic cylinder 7, and the air-purifying fabric spinning machine 1 A processing platform 4 is arranged on the left side of the front, an extended processing arm 5 is arranged on the front top of the processing platform 4, and a rotating shaft cylinder 6 is arranged on the inner and outer surface of one end of the extended processing arm 5, and the left and right sides of the processing platform 4 A heating plastic cylinder 7 is arranged on the inner surface, a console 2 is detachably installed on the right outer surface of the air-purifying fabric textile machine 1, a radiator 3 is arranged on the right outer surface of the console 2, and the air-purifying fabric textile A cooling radiator 8 is det...

Embodiment 2

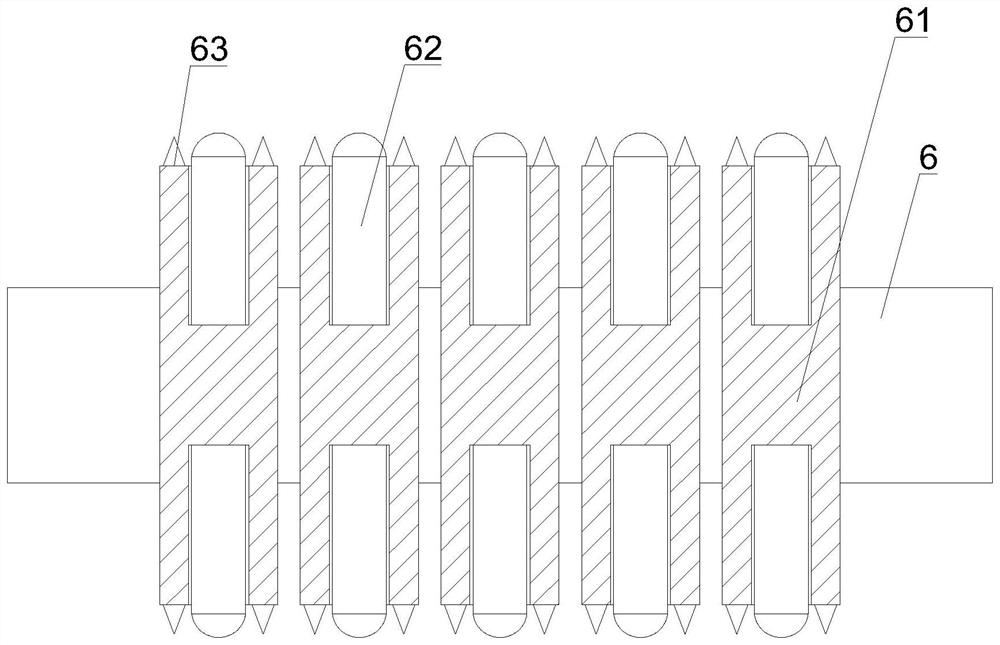

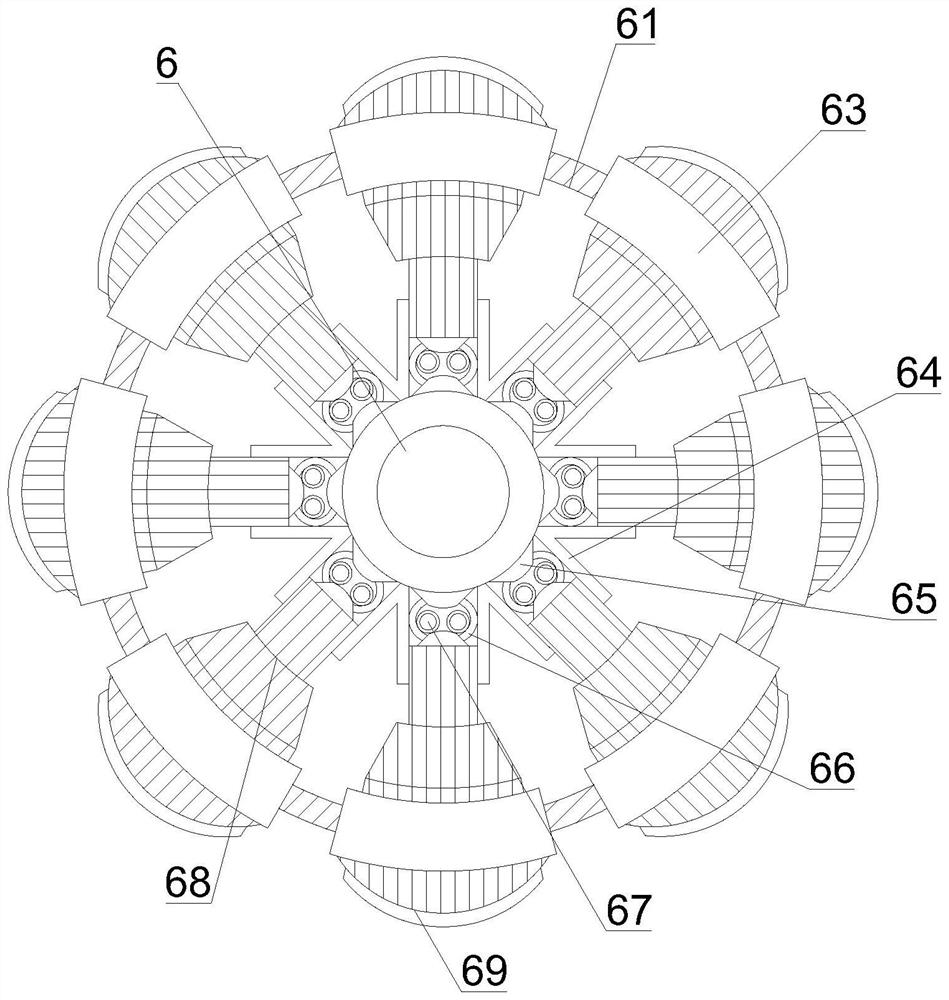

[0040] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a rotating processing disc 61 is provided on the outer surface of the rotating shaft cylinder 6, and a squeezing disc is arranged in the middle position on the outer surface of the rotating processing disc 61. Press the stretcher 62, and the outer surface of the rotating processing disc 61 is provided with fabric cone thorns 63 on the outer surface of the rotating processing disc 61, and the outer surface of the rotating shaft cylinder 6 is fixedly connected with a V-shaped guard plate 64, and the outer surface of the rotating shaft cylinder 6 A connection block 65 is fixedly connected to the top, and one end of the connection block 65 is detachably connected with an empty capsule 66, and one end of the connection block 65 is detachably connected with a telescopic fan 68, and one end of the telescopic fan 68 is connected with the empty capsule 66. ...

Embodiment 3

[0043] Such as Figure 1-6 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the outer surface of the thermoplastic cylinder 7 is detachably connected with a supporting hollow column 71, and the inside of the supporting hollow column 71 is provided with a conductive wire 72, one end of the supporting hollow column 71 is detachably connected with an outer layer sliding wheel 73, the outer surface of the outer layer sliding wheel 73 is provided with a gourd soft bar 74, and the outer surface of the gourd soft bar 74 is provided with a heating wire 75 , the gourd soft bar 74 is evenly distributed on the outer surface of the outer sliding wheel 73 .

[0044] In this embodiment, cooperate with the supporting hollow column 71 to increase the internal support of the outer sliding wheel 73, cooperate with the conductive wire 72 to guide the power supply to the inside of the heating wire 75, cooperate with the gourd soft bar 74 to doc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com