Coal mine hydrological dynamic monitoring system

A dynamic monitoring and hydrology technology, applied in mining equipment, mining equipment, earthwork drilling, etc., can solve problems such as fault water sloshing, rock mass cracks, and fault water flow direction changes, achieve rapid early warning and protection, and increase electrical conductivity. , the effect of good practicality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

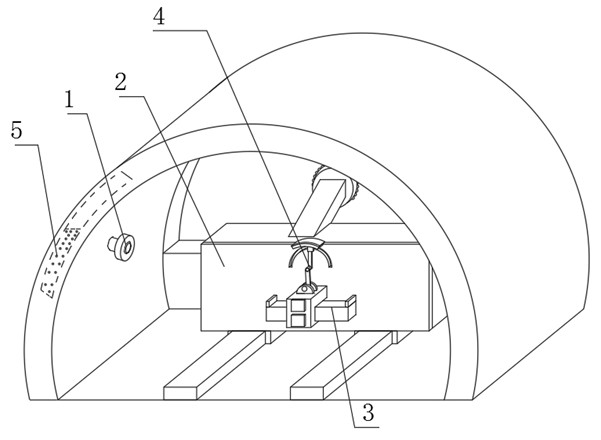

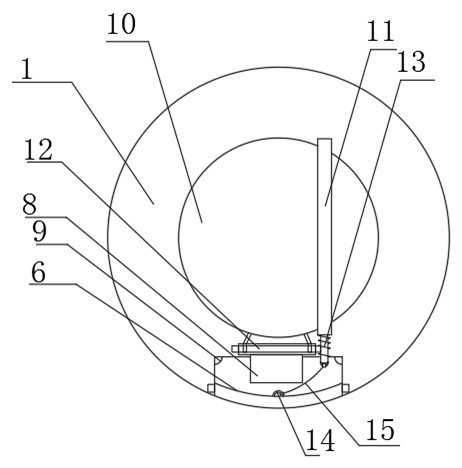

[0037] like Figure 1-7 As shown, a coal mine hydrology dynamic monitoring system includes graphite powder (5) for enhancing the conductivity of fault water, an injection bolt (1) for injecting the graphite powder (5) into a large water-rich fault, and an injection bolt (1) installed in the A fixed plate (2) on the back side of the excavation equipment, a shock-absorbing slide rail (3) is installed on the side of the fixed plate (2) away from the excavation equipment, and a monitoring mechanism (4) is slidably connected to the surface of the shock-absorbing slide rail (3). , and the surface of the fixing plate (2) is provided with an arc-shaped chute (201).

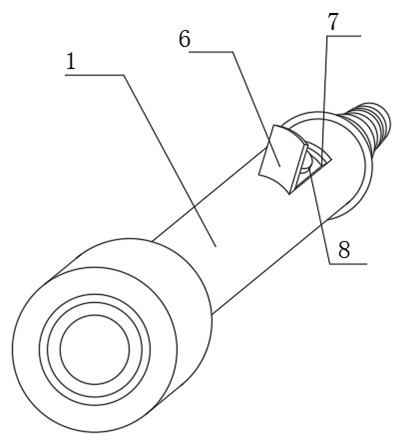

[0038] In this embodiment, a flap (6) is rotatably connected to the tail end of the injection bolt (1), a powder storage cavity is opened inside the injection bolt (1), and the graphite powder (5) is stored in the powder storage cavity, An inner cavity (7) is opened on the side of the injection anchor rod (1) and located...

Embodiment 2

[0047] like Figure 1-7 As shown, a coal mine hydrology dynamic monitoring system includes graphite powder (5) for enhancing the conductivity of fault water, an injection bolt (1) for injecting the graphite powder (5) into a large water-rich fault, and an injection bolt (1) installed in the A fixed plate (2) on the back side of the excavation equipment, a shock-absorbing slide rail (3) is installed on the side of the fixed plate (2) away from the excavation equipment, and a monitoring mechanism (4) is slidably connected to the surface of the shock-absorbing slide rail (3). , and the surface of the fixing plate (2) is provided with an arc-shaped chute (201).

[0048] In this embodiment, a flap (6) is rotatably connected to the tail end of the injection bolt (1), a powder storage cavity is opened inside the injection bolt (1), and the graphite powder (5) is stored in the powder storage cavity, An inner cavity (7) is opened on the side of the injection anchor rod (1) and located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com