Double-lead-screw linear mechanism of valve opening and closing structure

A technology of opening and closing structure and linear mechanism, which is applied in the direction of valve operation/release device, valve details, valve device, etc., to achieve the effect of reducing length space and improving load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

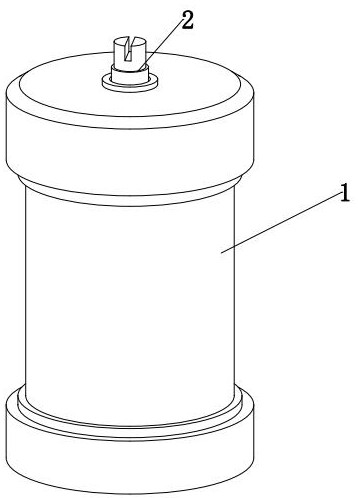

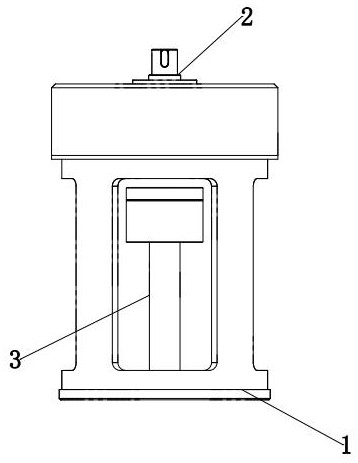

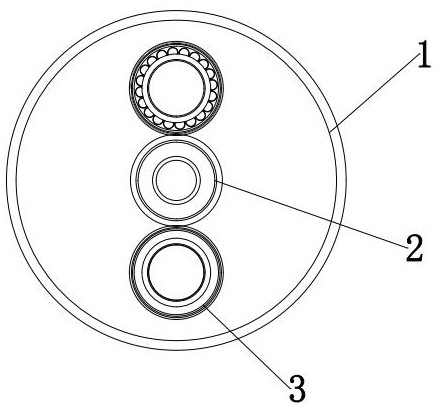

[0033] Please refer to Figure 1 to Figure 9

[0034] A double-screw linear mechanism with a valve opening and closing structure, including a main body 1, a transmission gear shaft 2 and a screw rod 3, the top of the main body 1 is fitted with the transmission gear shaft 2, and the middle part of the main body 1 is fitted with a screw rod 3, The top of the screw rod 3 fits the tooth mark of the transmission gear shaft 2 through the screw gear 4, the screw gear 4 passes through, the screw rod 3 is connected to the transmission gear shaft 2 through the top transmission gear 5, and the bottom opening of the middle part of the main body 1 is provided with a connection The bottom end of the threaded groove 6 is fitted with a restricting ring 7 , and the middle of the restricting ring 7 is fitted with an overlapping ring 702 .

[0035] Preferably, the planetary mechanism drives the multi-screw 3 to rotate, and adjusts the speed ratio by changing the number of gear teeth.

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com