Experimental device and method for realizing rock shearing under mining-induced stress gradient

A technology of dynamic stress and experimental equipment, applied in the direction of testing material strength by applying repetitive force/pulsation force, measuring equipment, testing material strength by applying stable shear force, etc., can solve the problem that does not take into account the gradient distribution of rock specimens The influence of pressure, the inability to accurately obtain rock shear mechanical properties, and complex structures have achieved stable and reliable rock unidirectional shear experiments and cyclic shear experiments, ensuring integrity and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing.

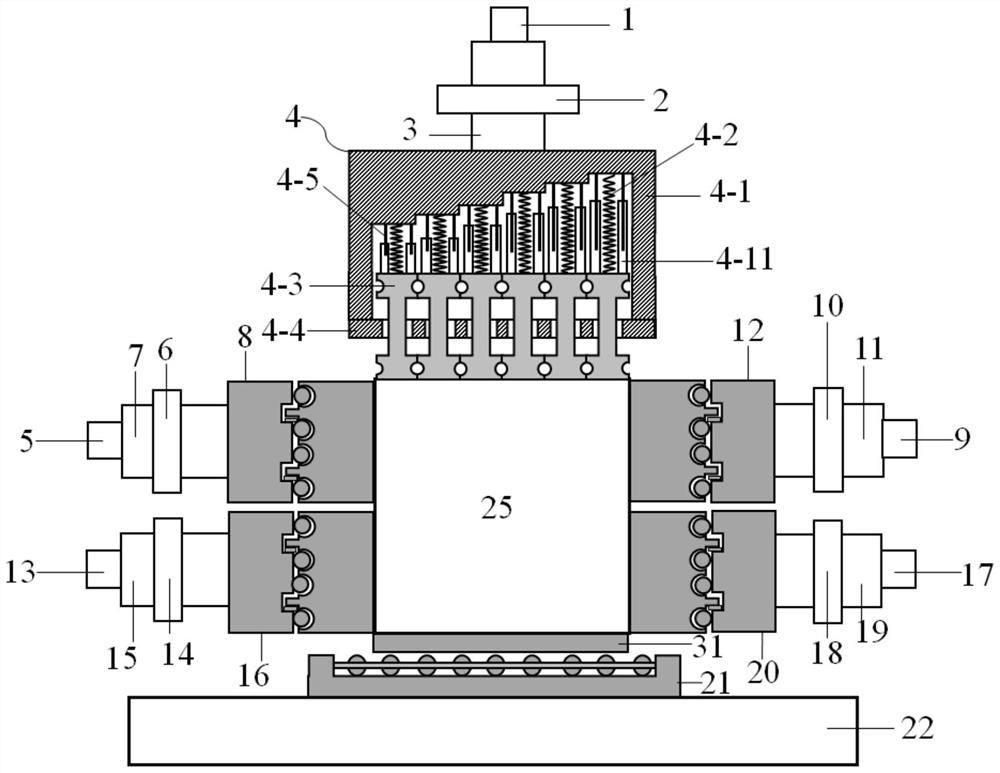

[0047] like Figure 1 to Figure 6 As shown, an experimental device for realizing rock shearing under a mining stress gradient includes a support 22, a normal loading mechanism, a left shear loading mechanism and a right shear loading mechanism;

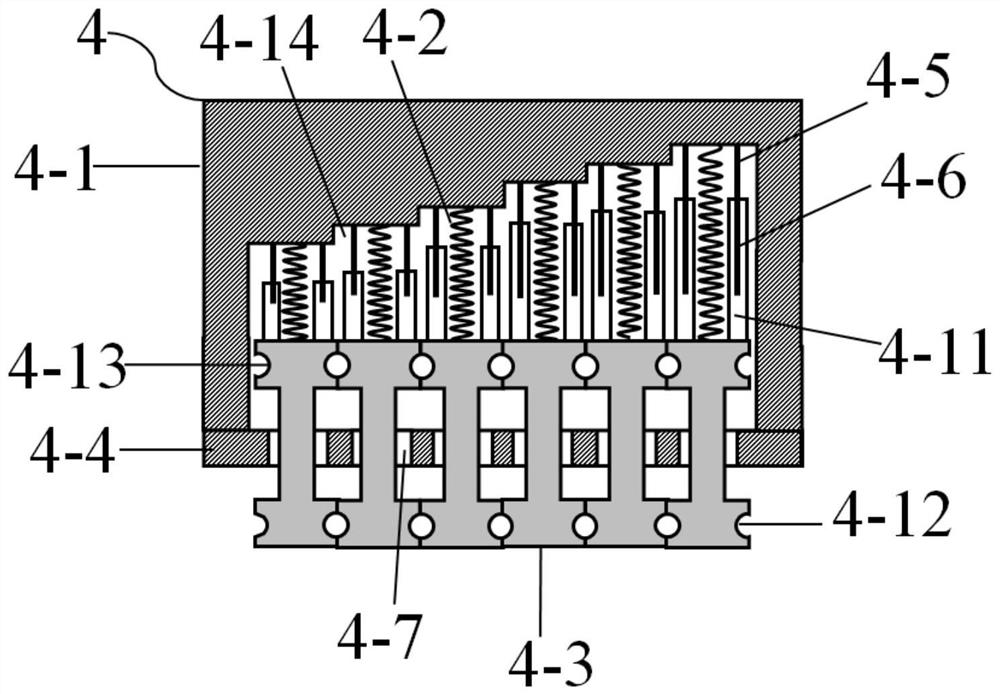

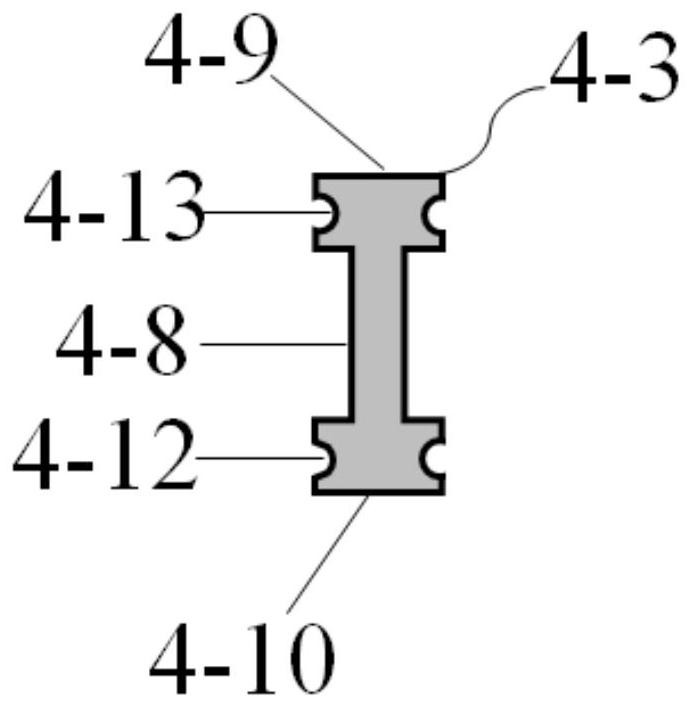

[0048] The support 22 is horizontally arranged at the bottom; the normal loading mechanism is arranged above the support 22, which consists of a normal gradient pressure constructor 4, a normal loading rod 3, a normal pressure sensor 1 and a normal displacement Composed of sensors 2; the normal gradient pressure constructor 4 is mainly composed of a support plate 4-4, a loading briquetting block 4-3, a cover plate 4-1 and a spring 4-2; the horizontal setting of the support plate 4-4 , on which a plurality of guide holes 4-7 are evenly opened along the left and right directions; the loading press blocks 4-3 are set in one-to-one co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com