Infrared double-station calibration method and calibration system

A calibration and infrared technology, applied to radio wave measurement systems, instruments, etc., can solve problems such as complex and time-consuming processes, poor environmental adaptability, and high visibility requirements, and achieve simple configuration and algorithm, high positioning accuracy, and environmental adaptability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

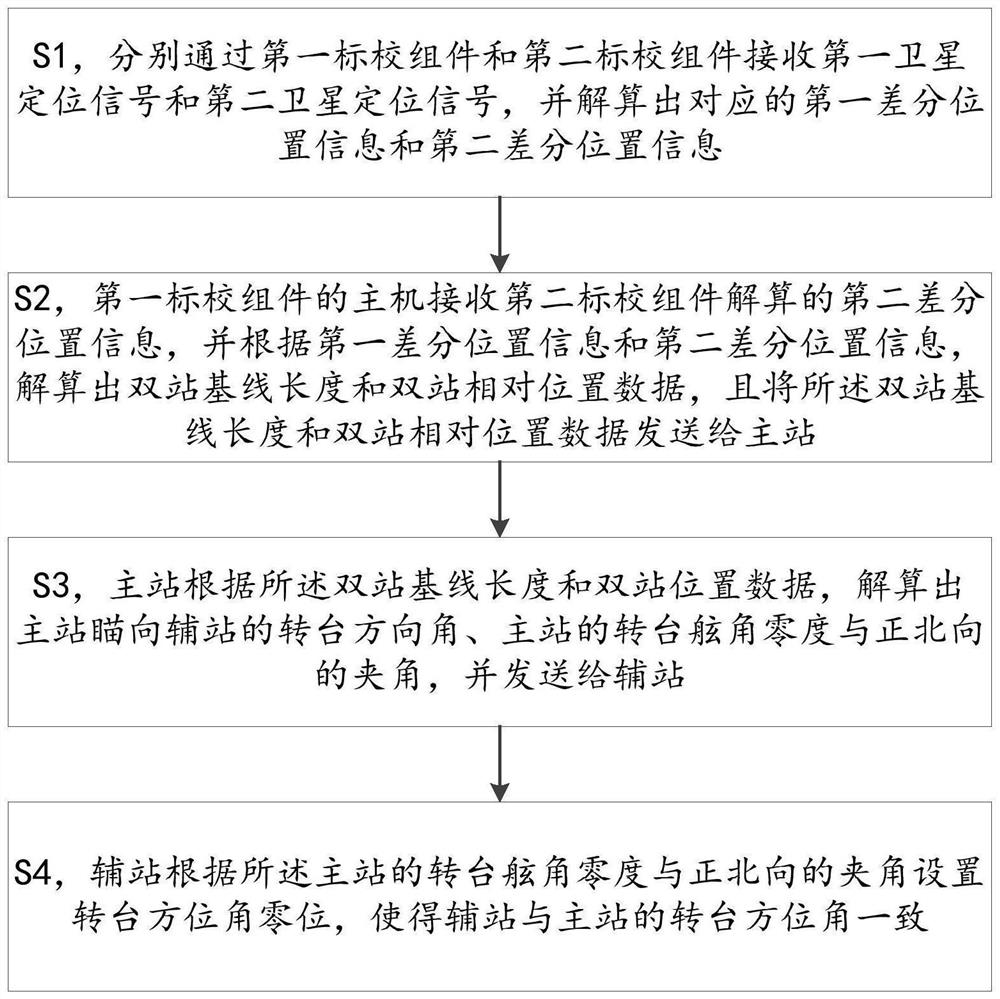

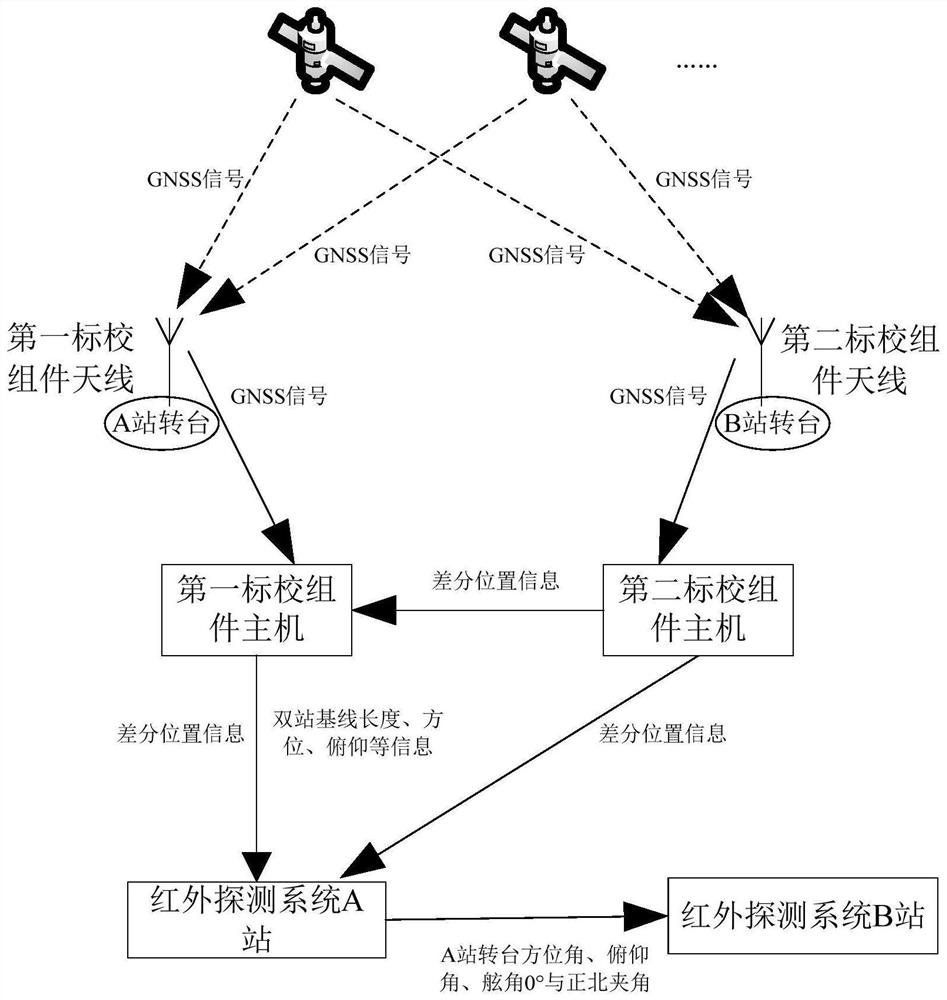

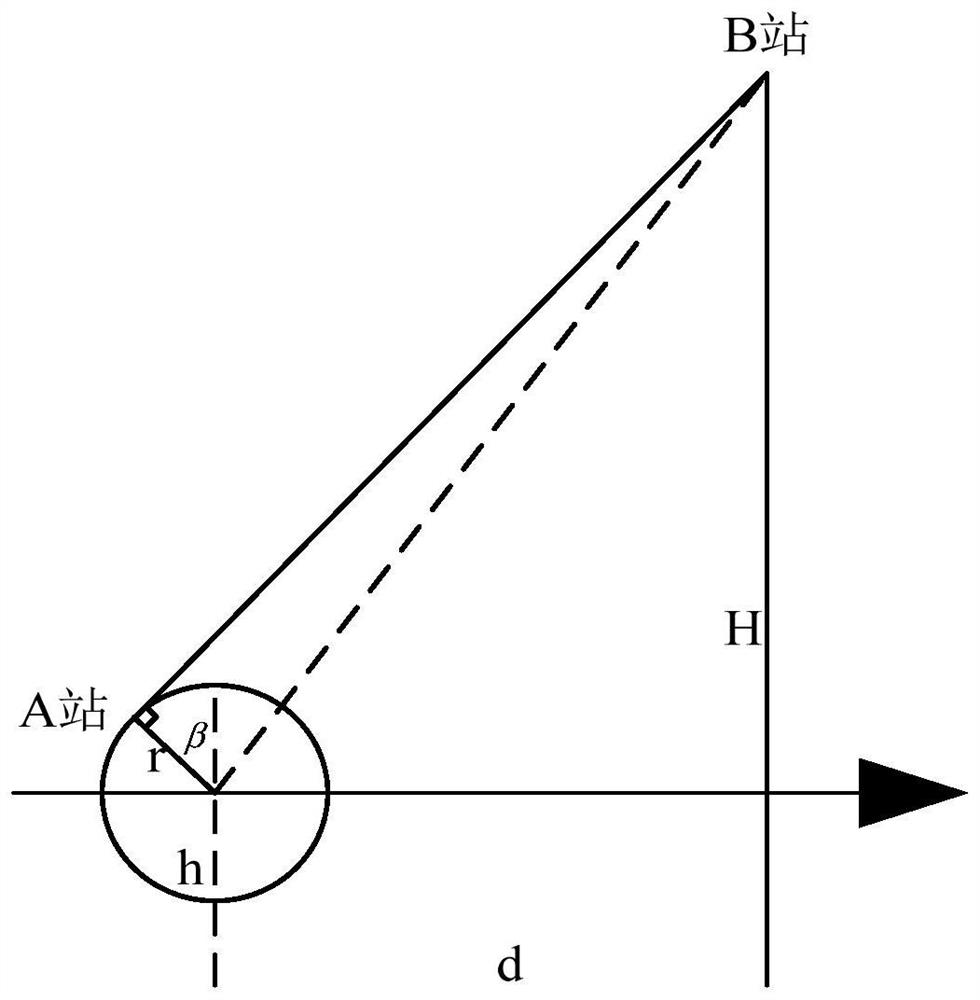

[0022] A kind of infrared two-station calibration method, see figure 1 , the infrared dual-station calibration method includes: receiving the first satellite positioning signal and the second satellite positioning signal through the first calibration component and the second calibration component respectively, and solving the corresponding first difference position information and the second difference Position information, wherein, the antenna of the first calibration component is installed on the turntable of the main station, the antenna of the second calibration component is installed on the turntable of the auxiliary station, the host of the first calibration component and the second The host of the second calibration component is installed on the system display console; the host of the first calibration component receives the second differential position information calculated by the second calibration component, and solves the problem according to the first differential ...

Embodiment 2

[0034] An infrared dual-station calibration method, the method mainly includes the following steps:

[0035] S1. Receive the first satellite positioning signal and the second satellite positioning signal through the first calibration component and the second calibration component respectively, and calculate the corresponding first differential position information and second differential position information, wherein the first differential position information The antenna of a calibration component is installed on the turntable of the main station, the antenna of the second calibration component is installed on the turntable of the auxiliary station, the host of the first calibration component and the host of the second calibration component are installed on the System display console.

[0036] In the present invention, according to the use environment and use requirements of the infrared detection system, the quick calibration configuration based on the calibration components...

Embodiment 3

[0067] An infrared dual-station calibration system, see Figure 4 , the infrared dual-station calibration system includes a first calibration assembly 41 and a second calibration assembly 42, the antenna of the first calibration assembly is installed on the turntable of the master station 43, and the antenna of the second calibration assembly is installed on the auxiliary station 44 On the turntable, the host of the first calibration component 41 and the host of the second calibration component 42 are installed on the system display console 45 .

[0068] Wherein, the first calibration component 41 is used to receive the first satellite positioning signal and calculate the corresponding first differential position information; it is also used to receive the second differential position information calculated by the second calibration component 42, And according to the first differential position information and the second differential position information, calculate the bi-stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com