Follow-up coil wiring device used under high-vacuum and high-voltage conditions

A technology of a follow-up coil and a wiring device, which is applied in the direction of the two-part connection device, the installation of the cable, the parts of the connection device, etc., to achieve the effect of reliable insulation connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

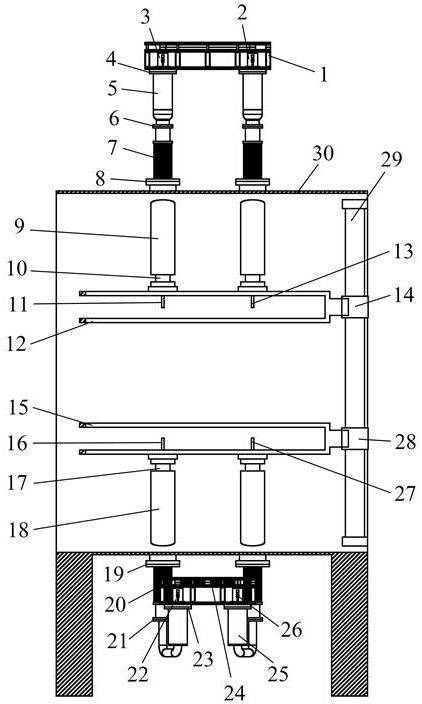

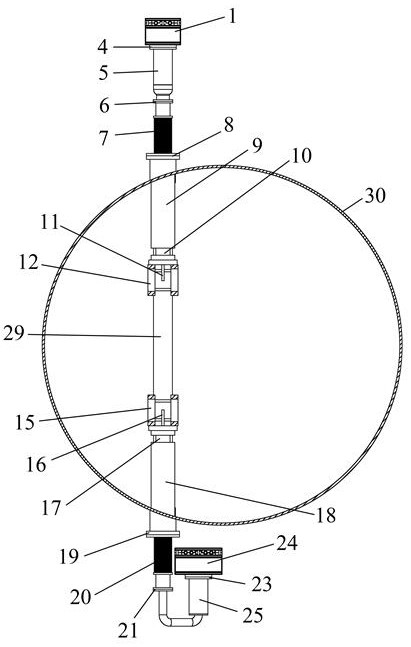

[0054] Specific implementation mode 1, refer to Figures 1 to 3 Describe this embodiment in detail. A servo coil wiring device used under high vacuum and high voltage conditions described in this embodiment includes: an upper servo coil wiring device, a lower servo coil wiring device, and a guide post 29 , Vacuum bulkhead 30.

[0055] The upper servo coil wiring device includes: upper connector 1, upper No. 1 sealed high-voltage electrode 2, upper No. 2 sealed high-voltage electrode 3, upper electrode flange 4, upper electrode sleeve 5, upper sleeve flange 6, upper thread Wave tube 7, upper motion support flange 8, upper motion support sleeve 9, upper motion support tube 10, upper load connection terminal 11, upper follower bracket 12, upper load connection terminal 13, upper guide column slide Set of 14.

[0056] The upper connector 1 is placed on the upper part of the vacuum chamber, and is used to connect the coaxial cable outside the vacuum chamber to the input and outpu...

specific Embodiment approach 2

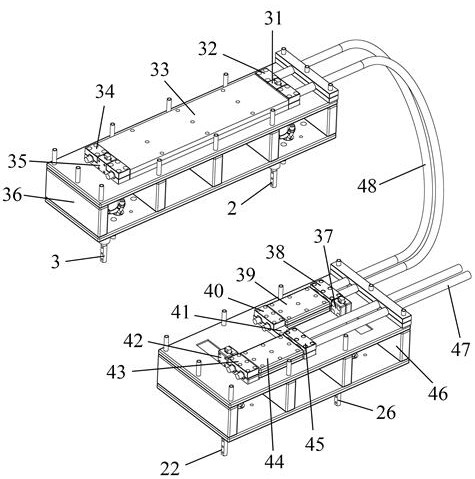

[0074] Specific Embodiment 2. This embodiment is a further description of the servo coil wiring device used in high vacuum and high voltage conditions described in Embodiment 1. In this embodiment, the upper connector 1 includes: No. 1 electrode joint 31 , upper series coaxial cable outer core joint 32 , upper insulating fixing plate 33 , upper series coaxial cable inner core joint 34 , upper second electrode joint 35 , upper connector skeleton 36 .

[0075] The last No. 1 electrode joint 31 is a metal conductor, which is used to connect and fix the metal conductor in the No. 1 sealed high-voltage electrode 2, and is connected with the outer core joint 32 of the upper series coaxial cable, so that the pulse current is transmitted by the series coaxial cable 48. The input of the outer core to the current inflow end of the upper magnetic mirror field coil in the cabin;

[0076] The upper series coaxial cable outer core connector 32 is a metal conductor, two in total, for connect...

specific Embodiment approach 3

[0081] Specific Embodiment 3. This embodiment is a further description of the servo coil wiring device used in high vacuum and high voltage conditions described in Embodiment 1. In this embodiment, the lower connector 24 includes: No. 2 electrode connector 37, lower serial coaxial cable outer core connector 38, lower insulating fixing plate 39, lower serial coaxial cable inner core connector 40, connecting conductor 41, next electrode connector 42, output coaxial cable inner core connector 43. The output coaxial cable insulation fixing plate 44, the output coaxial cable outer core connector 45, and the lower connector skeleton 46.

[0082]The second No. electrode joint 37 is a metal conductor, which is used to connect and fix the metal conductor in the No. 2 sealed high-voltage electrode 26, and is connected with the outer core joint 38 of the lower series coaxial cable, so that the pulse current is passed by the magnetic mirror field in the cabin. The output end of the coil c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com