Impact type crushing device for ore mining

A crushing device and impact-type technology, applied in earth-moving drilling, slitting machinery, vibration suppression adjustment, etc., can solve problems such as the expansion of cracked ore gaps, the need for more manpower for motor equipment, and the impact of ore mining efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

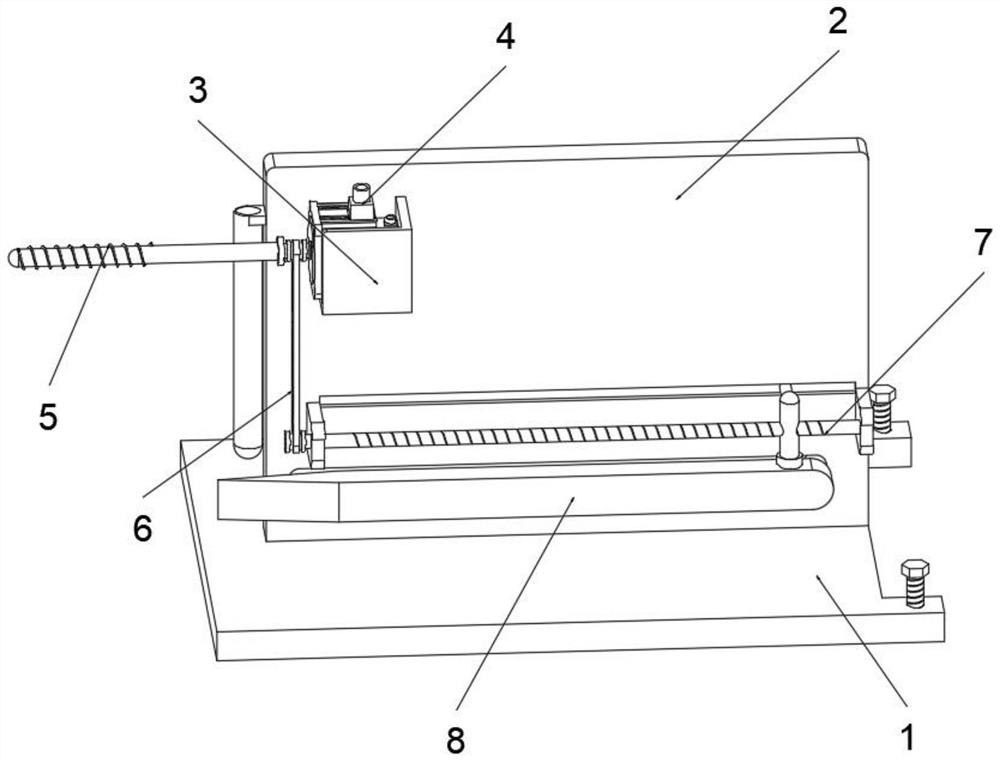

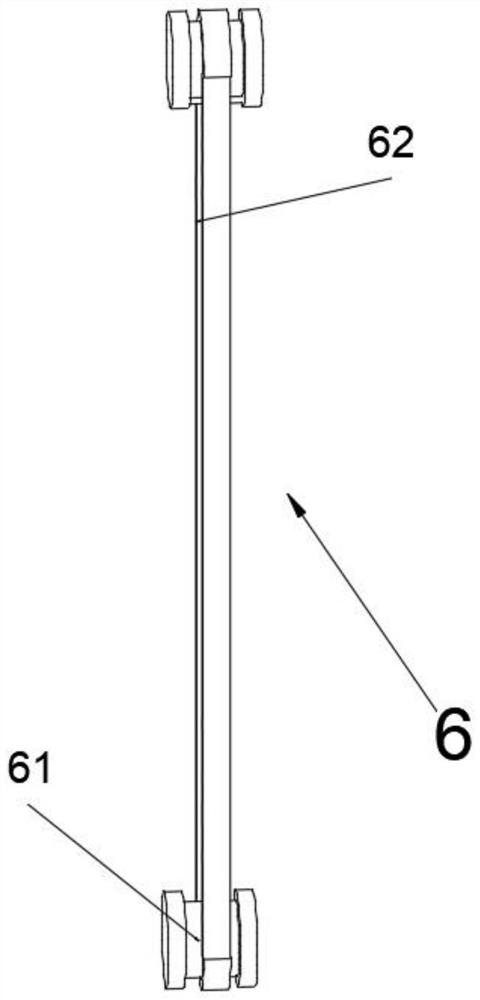

[0039] see Figure 1-Figure 4As shown, the purpose of this embodiment is to provide a crushing device for ore mining based on the impact type, at least including:

[0040] Base plate 1, fixed plate 2 is installed on the surface of base plate 1, housing 3 is installed on the surface of fixed plate 2, motor 4 is arranged inside the housing 3, one end of motor 4 is connected with rotating rod 5, one side of rotating rod 5 Protruding from the side of the bottom plate 1, the rotating rod 5 is used to break the ore;

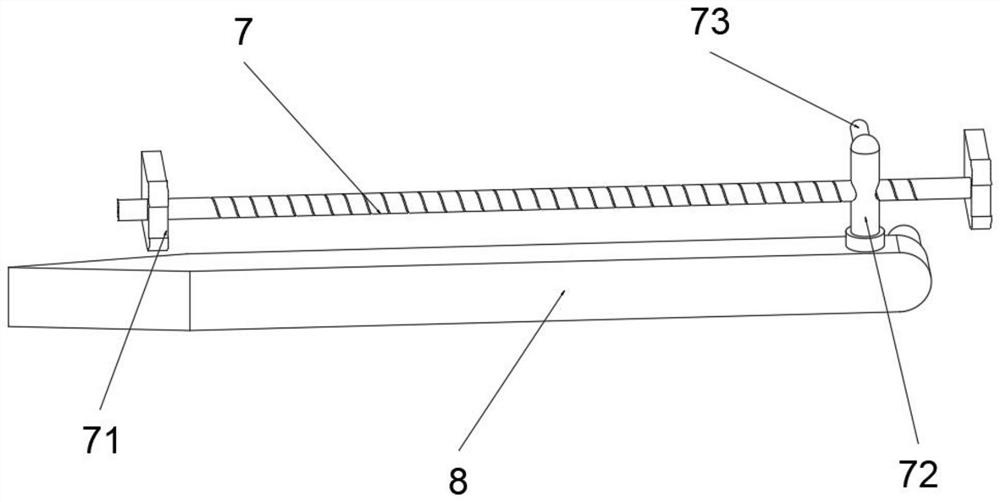

[0041] Screw mandrel 7, the end of screw mandrel 7 is provided with fixed block 71, and fixed block 71 is fixedly connected with fixed plate 2, and the surface screw thread of screw mandrel 7 is connected with screw mandrel nut 72, and screw mandrel nut 72 is provided with limiting block 73 , the limit block 73 is in contact with the fixed plate 2, the bottom of the screw nut 72 is equipped with a rupture plate 8, the rupture plate 8 and the rotating rod 5 are on the ...

Embodiment 2

[0049] Considering that the installation of the rupture plate 8 is still not up to the standard for expanding the ore gap, this embodiment makes the following improvements on the basis of embodiment 1, such as Figure 5-Figure 7 Shown:

[0050] The surface of the rupture plate 8 is oppositely provided with a concave cavity 81, and the interior of the cavity 81 is symmetrically installed with mounting blocks 82, and an inner plate 83 is hinged between the mounting blocks 82, and the inner plate 83 is used to expand the thickness of the rupture plate 8. When When the cracking plate 8 in Embodiment 1 still cannot expand the gap of ore fragmentation as far as possible during the deep process, the inner plate 83 is rotated along the hinge to make the inner plate 83 expand outward in the concave cavity 81, When the rupture plate 8 goes deep inward, when the inner plate 83 touches the gaps of the ore, the distance between the gaps will be enlarged again, so as to deepen the expansion...

Embodiment 3

[0053] Considering that the broken ore will roll onto the bottom plate 1 and affect the normal driving of the cracking plate 8, the difference between this embodiment and Embodiment 1 is that, as Figure 8-Figure 10 Shown:

[0054] The surface of the bottom plate 1 is provided with a blocking piece 9, the blocking piece 9 includes a connecting arm 91, the connecting arm 91 is in a “zigzag” shape, the surface of the fixed plate 2 is provided with a top sliding cavity 24, and the connecting arm 91 runs through the top sliding cavity 24 and slides on Inside, the transverse part of the connecting arm 91 is fixedly connected with the screw nut 72, the bottom of the connecting arm 91 is equipped with a sliding arm 92, one side of the sliding arm 92 is provided with a connecting rod 93, and the end of the connecting rod 93 is provided with a baffle 95. There is a gap between the rupture plate 8 and the bottom plate 1. The gap is used to prevent the crushed ore from rolling down and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com