Six-section roll forming and three-roll rolling mill for rolling non-ferrous metals

A non-ferrous metal, three-roll mill technology, applied in the direction of metal rolling, metal rolling, rolls, etc., can solve the problems of sticking and smooth pipe throwing, unable to achieve bite rotation, etc., to avoid scratches and smooth rolling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

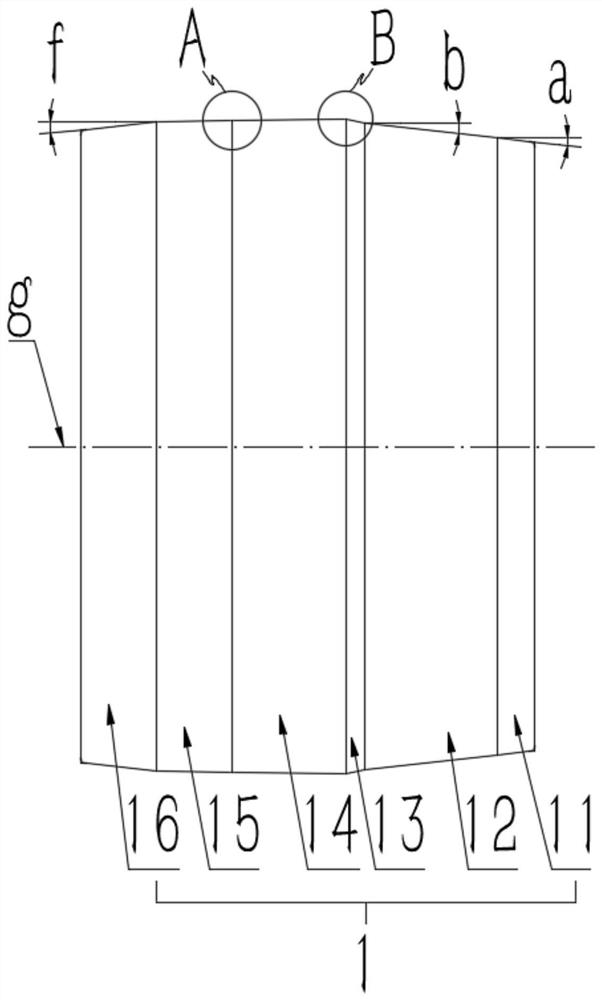

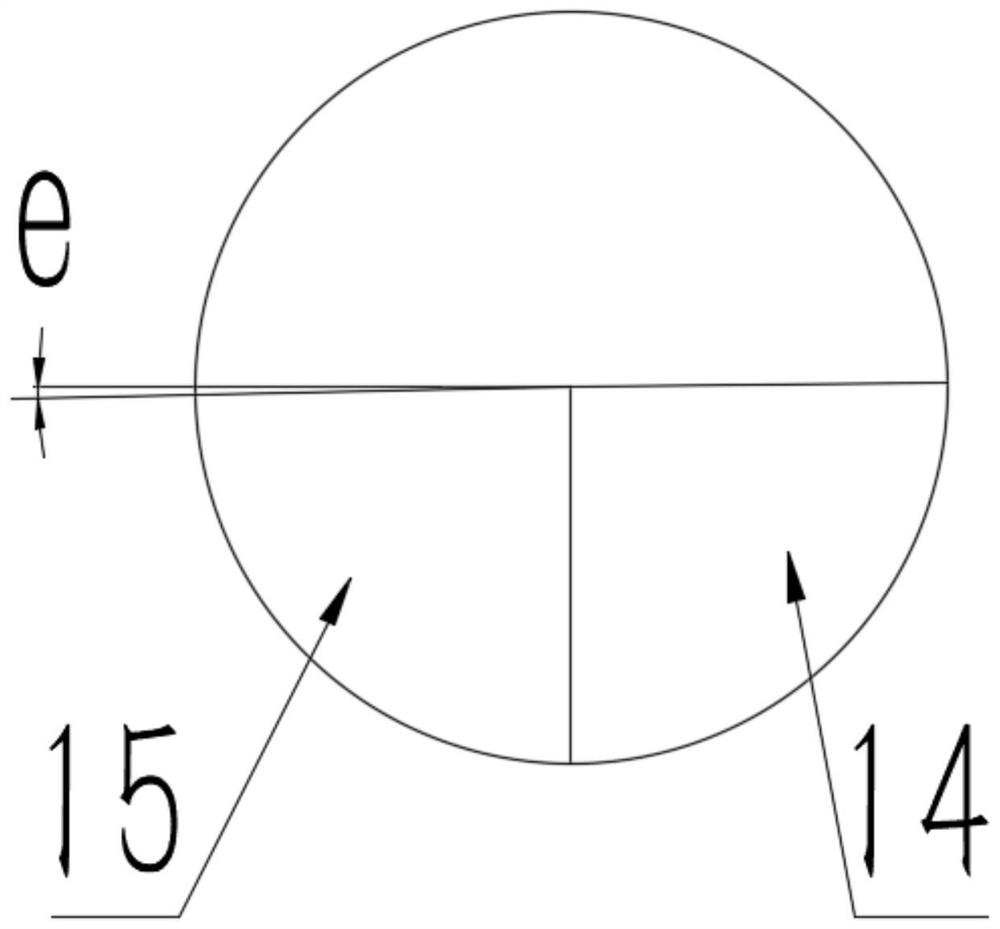

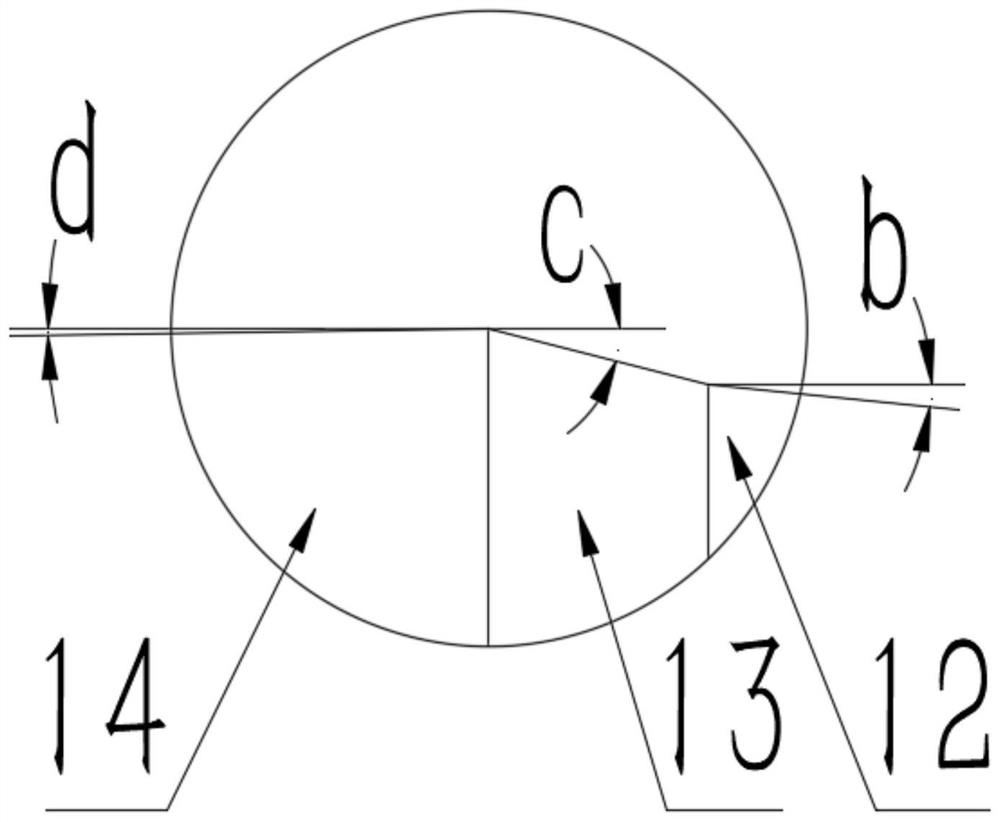

[0030] as Figures 1 through 7 As shown, the present embodiment provides a non-ferrous metal rolling with six segments of the roll, comprising: a roller body 1, the roller body 1 from right to left sequentially formed a contact bite segment 11, a rotary rolling section 12, a collection section 13, a mean integral section 14, a returning segment 15 and a throwing segment 16, the contact bite segment 11, a rotary rolling segment 12, a set variable segment 13, a mean integral segment 14, a returning segment 15 and a throwing segment 16 are cone surfaces.

[0031] Further, the angle between the busbar of the contact biting segment 11 and the rotation axis g of the roller body 1 (angle a in FIG. 1) ranges from 7 ° to 9 °, the angle between the busbar of the rotating rolling section 12 and the rotation axis g of the roller body 1 (angle b in FIG. 1) ranges from 6 ° to 7 °, the busbar of the set variable section 13 and the angle of the rotation axis g of the roller body 1 (angle c in fig....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com