Oiling device for adjusting diameter uniformity of fibers

An oiling device and fiber diameter technology, which is applied in the field of fiber production, can solve the problems of large fiber diameter differences and large dispersion, and achieve the effects of increasing full package rate, improving stability, and reducing diameter differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

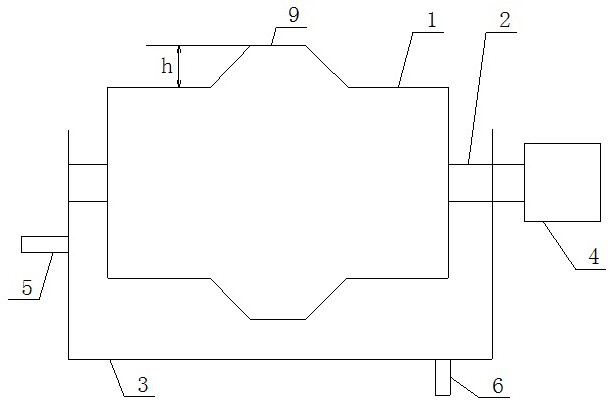

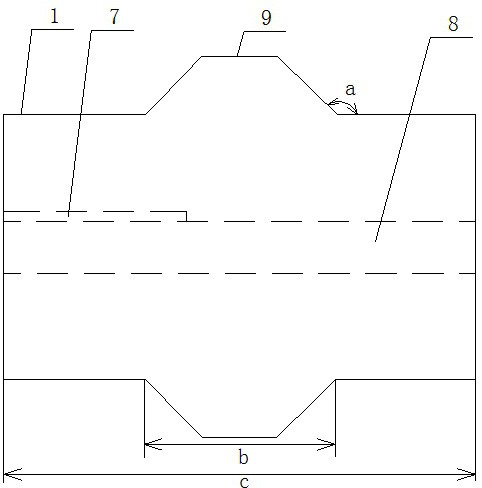

[0032] Such as figure 1 and figure 2 Shown:

[0033] The present invention provides an oiling device for adjusting the uniformity of fiber diameter provided by the present invention, comprising an oiling roller body 1, the middle part of the oiling roller body 1 has a protruding structure 9, and the protruding structure 9 It is arranged around the outer wall of the oiling roller body 1 .

[0034] The oiling device provided by the present invention for adjusting the uniformity of the fiber diameter can adjust the consistency of the linear speed of the monofilament through the convex structure 9, so as to effectively adjust the uniformity of the diameter of the fibers distributed on the oiling roller and reduce the The difference in fiber diameter between the middle and both sides of the oiling roller reduces the dispersion of fiber diameter and improves its stability. The oiling device provided by the present invention for adjusting the uniformity of fiber diameter can draw...

Embodiment 2

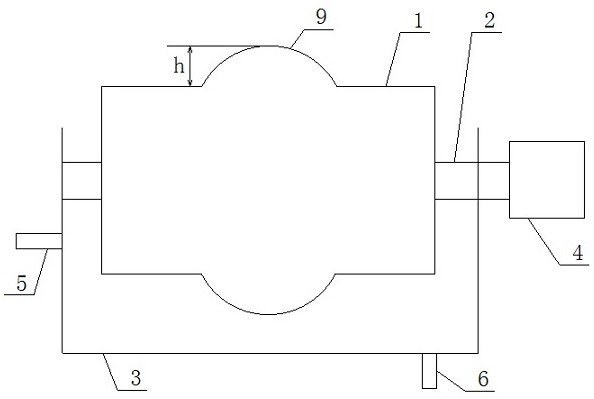

[0049] Such as image 3 and Figure 4 Shown:

[0050] The difference between this embodiment and embodiment 1 is:

[0051] The outer surface of the convex structure 9 is an arc surface;

[0052] The maximum height h of the convex structure 9 protruding outward is 15mm;

[0053] The length b of the protruding structure 9 accounts for 30% of the length c of the oiling roller body 1;

[0054] Others are the same as in Example 1.

Embodiment 3

[0056] Such as Figure 5 Shown:

[0057] The difference between this embodiment and embodiment 1 is:

[0058] The outer surface of the convex structure 9 is an arc surface;

[0059] The maximum height h of the convex structure 9 protruding outward is 5 mm;

[0060] The length b of the protruding structure 9 accounts for 10% of the length c of the oiling roller body 1;

[0061] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com