Method and device for evaluating lubrication state of each position of gearbox and vehicle

A gearbox and status technology, applied in the direction of measuring devices, transmission parts, gear lubrication/cooling, etc., can solve the problems of not being able to respond to local lubrication conditions, and achieve the effect of facilitating subsequent maintenance and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

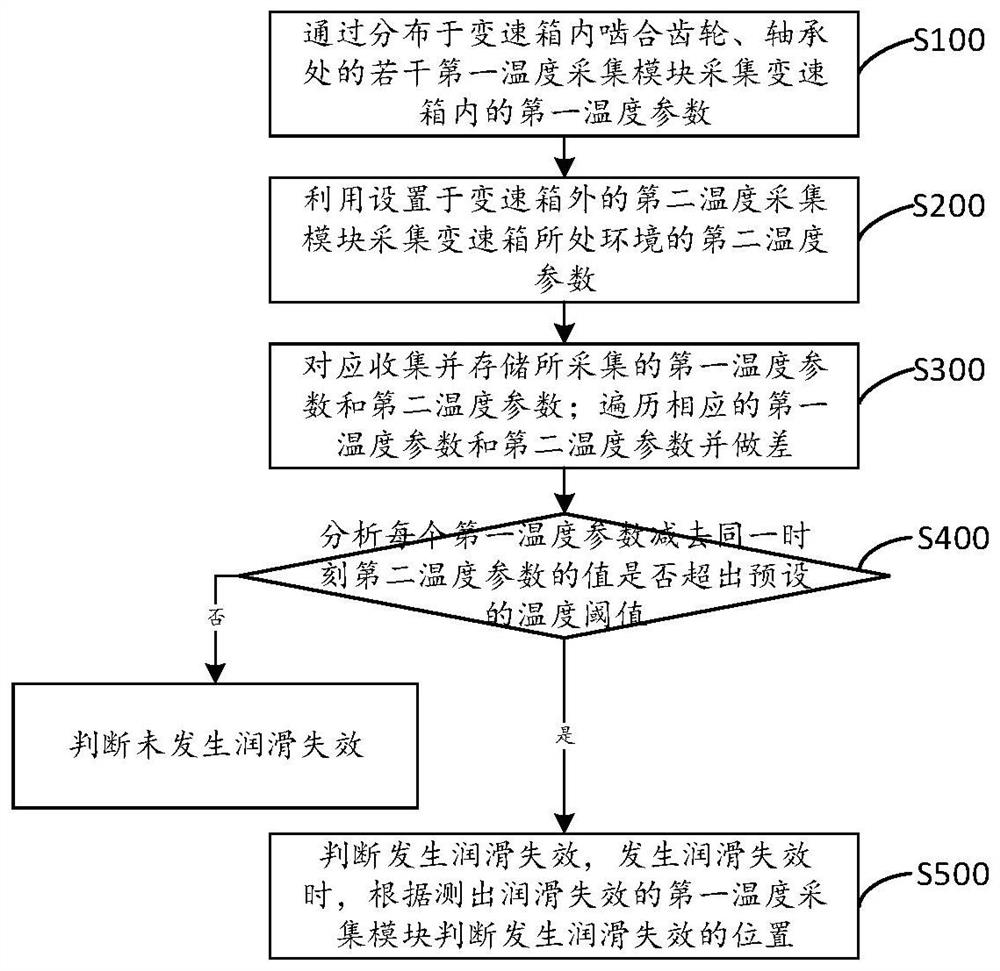

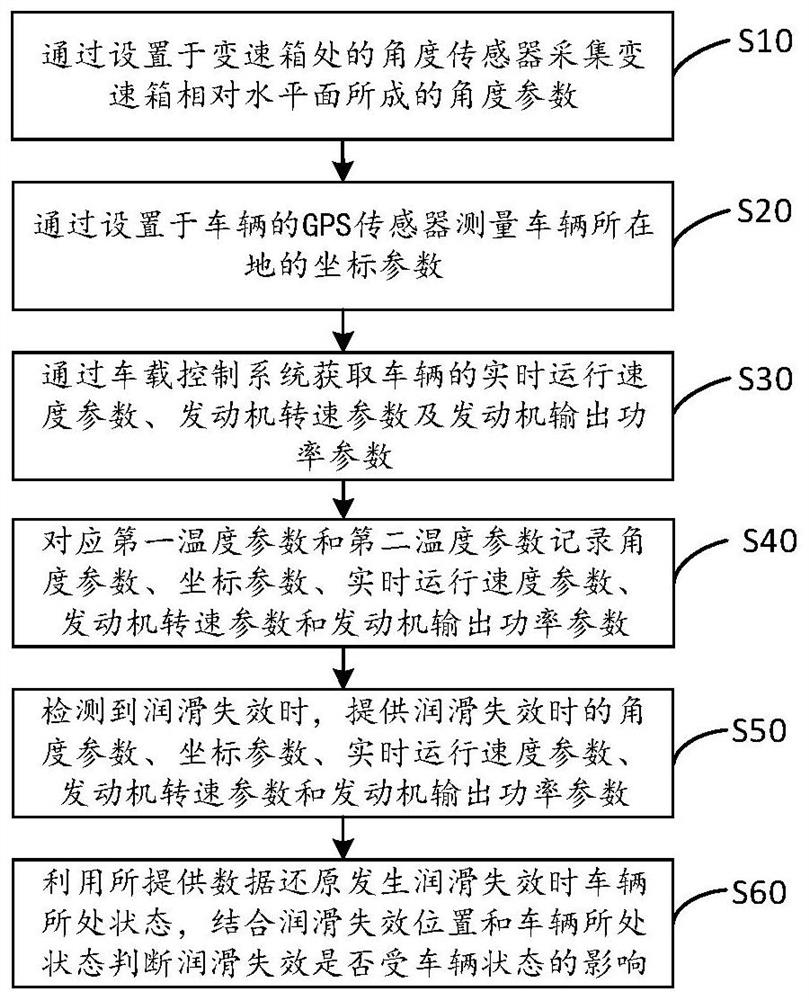

[0039] refer to figure 1 As shown, the embodiment of the present invention provides a method for evaluating the lubrication status of each position of the gearbox, including:

[0040] S100, collecting first temperature parameters in the gearbox through a plurality of first temperature acquisition modules distributed at the internal meshing gears and bearings of the gearbox;

[0041] S200, using a second temperature acquisition module arranged outside the gearbox to collect a second temperature parameter of the environment where the gearbox is located;

[0042] S300, correspondingly collecting and storing the collected first temperature parameter and second temperature parameter; traversing the corresponding first temperature parameter and second temperature parameter and making a difference;

[0043] S400, analyze whether the value of each first temperature parameter minus the second temperature parameter at the same time exceeds the preset temperature threshold, if yes, exec...

Embodiment 2

[0060] refer to Figure 4 As shown, the embodiment of the present invention provides a device for evaluating the lubrication status of each position of the gearbox, including: a first temperature acquisition module, a plurality of the first temperature acquisition modules are distributed and arranged at the internal meshing gear and the bearing of the gearbox, and collect the variable speed The first temperature parameter in the box; in the specific implementation process, refer to Figure 5 and Figure 6 As shown, a feasible first temperature acquisition module 1 includes a fixed ring 11 sleeved and fixed on the rotating shaft, a temperature sensor 12 is fixedly arranged on the fixed ring 11, and the fixed ring 11 fits a gear or The bearing is fixed, and the temperature at the meshing gear and the bearing is measured by a temperature sensor.

[0061] A second temperature acquisition module, the second temperature acquisition module is arranged outside the gearbox, and is us...

Embodiment 3

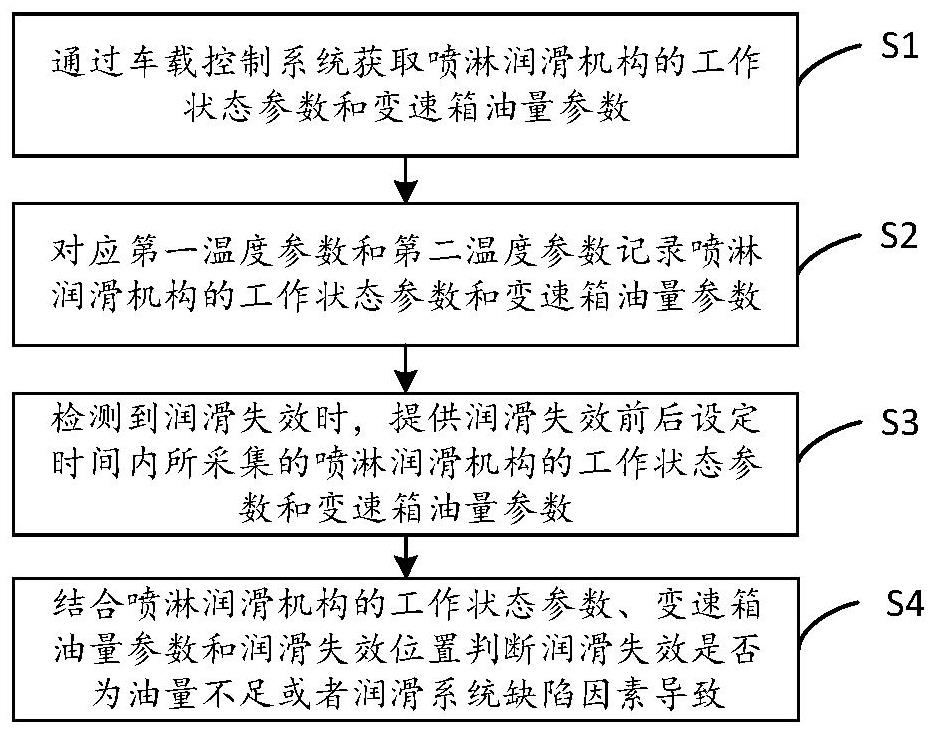

[0067] The embodiment of the present invention provides a vehicle using a device for evaluating the lubrication status of each position of the gearbox, including: a vehicle body, equipped with a device for evaluating the lubrication status of each position of the gearbox, and the vehicle control system in the vehicle body is electrically connected to the spray lubrication mechanism. When the on-board control system of the device for evaluating the lubrication status of each position of the gearbox judges that the gearbox has lubrication failure, the on-board control system controls the spray lubrication mechanism to increase the fuel injection amount. Specifically, formulate the corresponding relationship between the temperature difference and the increased fuel injection quantity, wherein the temperature difference refers to the maximum value of the difference between the first temperature parameter and the second temperature parameter judged as lubrication failure; the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com