Hard rock tunnel presplitting smooth surface combined blasting structure and method for reducing blasting vibration

A blasting vibration and pre-splitting technology, applied in tunnels, blasting, earthwork drilling, etc., can solve problems such as penetration of peripheral eye blasting cracks, tunnel instability, induced rock burst disasters, etc., to reduce blasting difficulty and reduce blasting vibration. , to ensure the effect of blasting progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

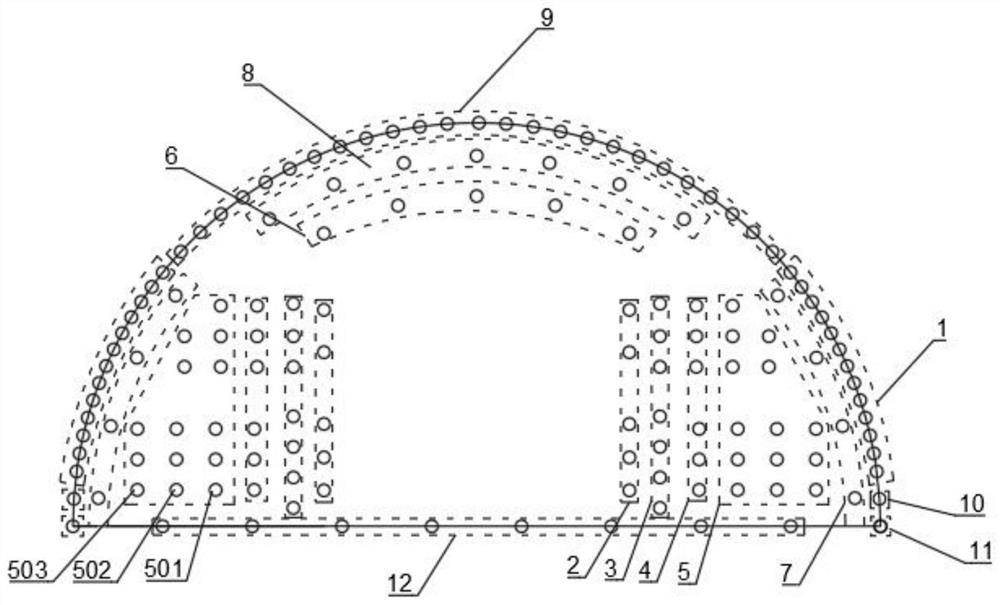

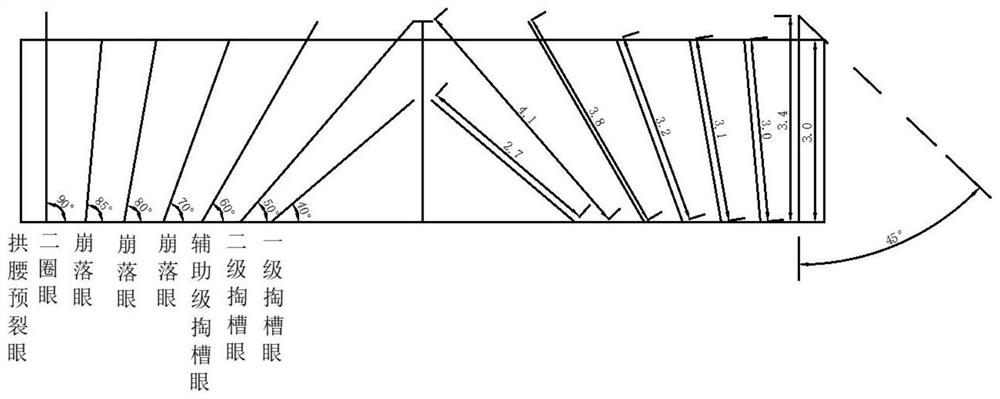

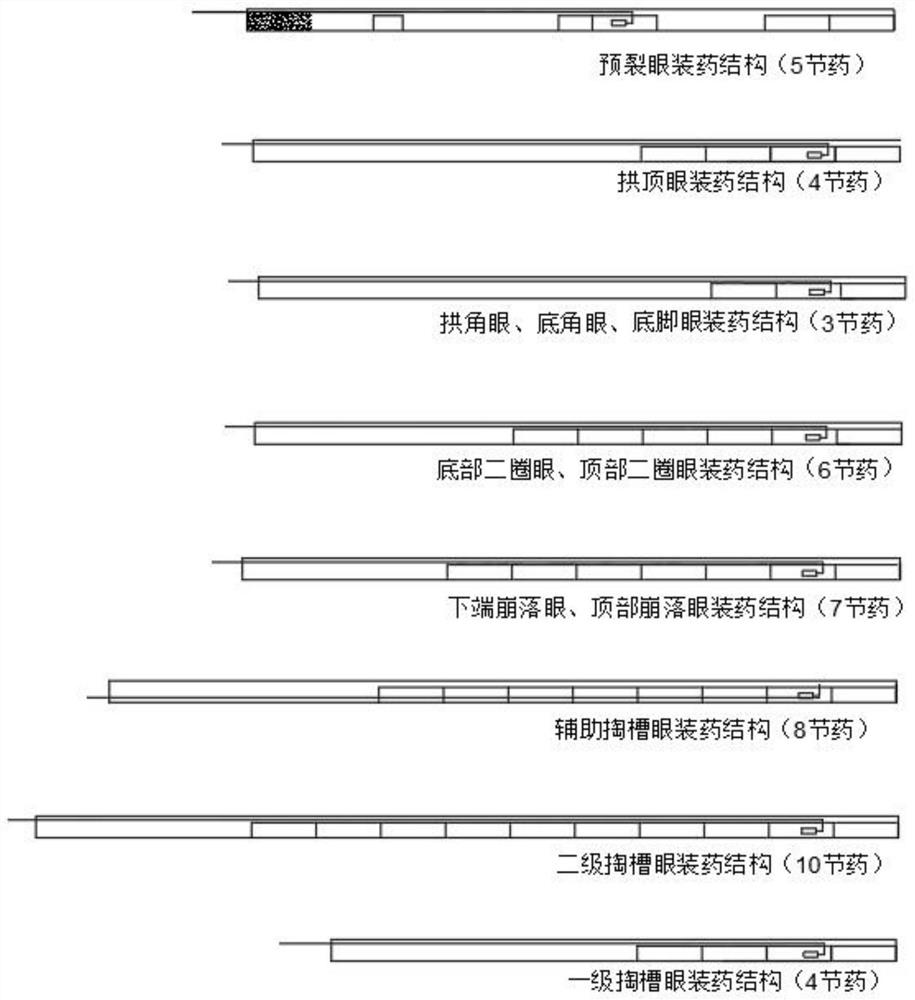

[0030] refer to Figure 1-3As shown, a hard rock tunnel pre-splitting and smooth surface combined blasting structure that reduces blasting vibration, including arch waist pre-splitting eye 1, first-level cutting eye 2, second-level cutting eye 3, auxiliary level cutting eye 4, lower end Caving eye 5, top caving eye 6, bottom second ring eye 7, top second ring eye 8, vault eye 9, arch corner eye 10, bottom corner eye 11 and bottom plate eye 12, arch waist pre-crack eye 1 is set in the blasting On the contour line of the tunnel arch waist, the first-level cutout hole 2, the second-level cutout hole 3, the auxiliary level cutout hole 4 and the lower end caving eyelet 5 are symmetrically arranged in the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com