High-frequency and high-speed PCB (printed circuit board) copper-clad laminate

A copper-clad laminate, high-speed technology, applied in the direction of printed circuit components, printed circuits, electrical components, etc., can solve problems such as looseness, bulging and bonding, to improve flatness, increase compactness, and reduce gas residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

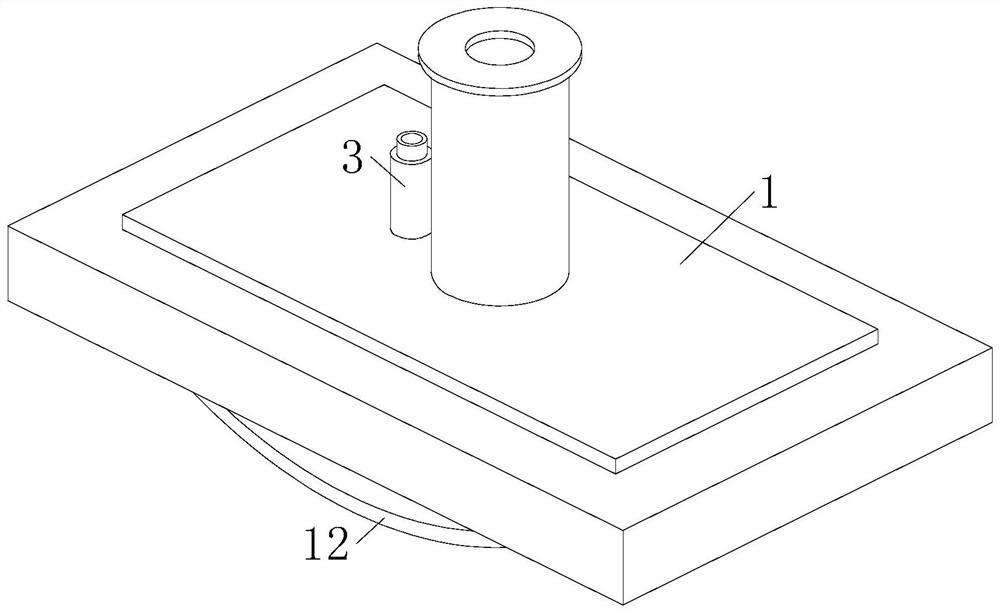

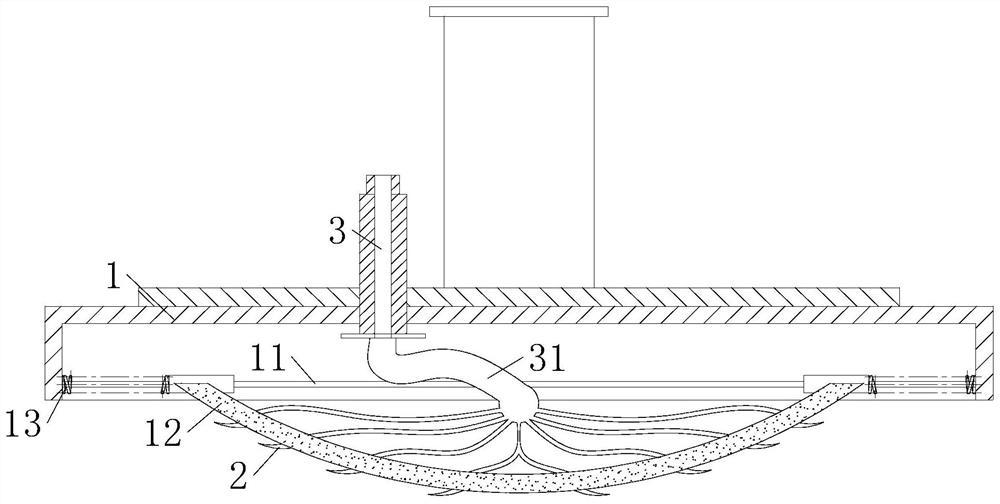

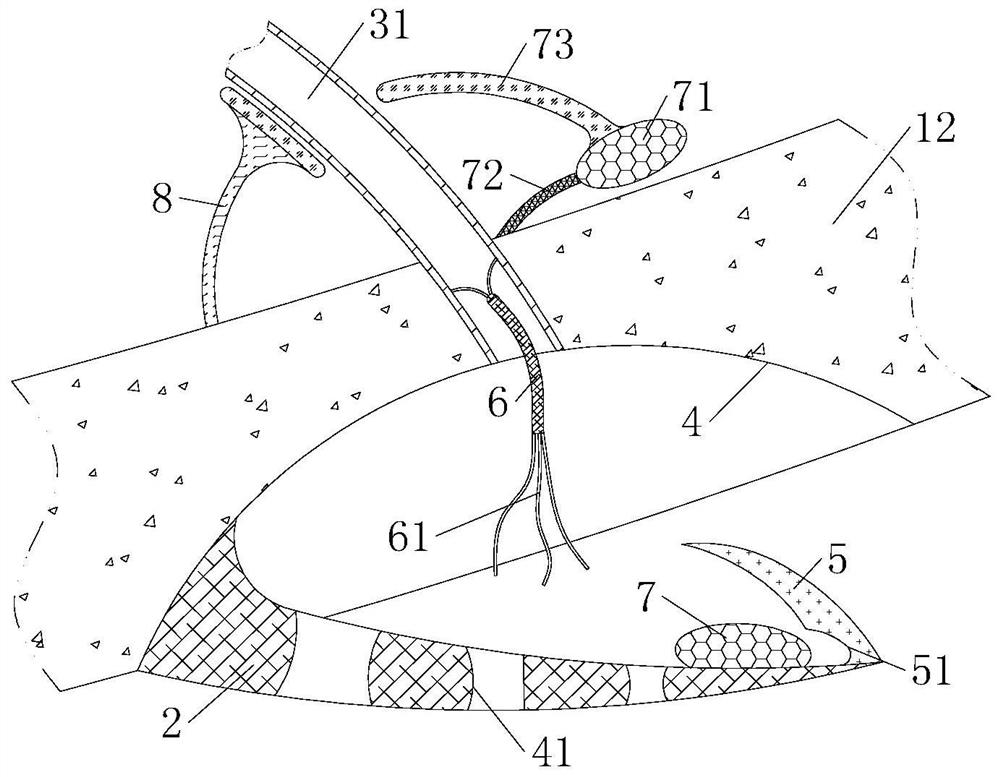

[0028] Such as Figure 1 to Figure 3 As shown, a high-frequency high-speed PCB copper-clad laminate described in the embodiment of the present invention includes a pressing seat 1; a slide bar 11 is fixedly connected to the bottom of the pressing seat 1; 12. Both ends of the elastic pressure plate 12 are slidably connected to the slide bar 11; a spring 13 is installed between the elastic pressure plate 12 and the inner side wall of the pressing seat 1; the middle part of the elastic pressure plate 12 is lower than the two ends; When in use, move the pressing seat 1 to the top of the substrate, and then place the copper foil on the top of the substrate. At this time, the pressing seat 1 can be pressed down, so that the elastic pressing plate 12 can squeeze the copper foil and the substrate. During the pressing process of the copper foil and the substrate, the middle part of the elastic pressing plate 12 will first contact the substrate. During the continuous pressing down of th...

Embodiment 2

[0038] Such as Figure 4 As shown in Comparative Example 1, another embodiment of the present invention is: multiple sets of protective elastic sheets 91 are provided on both sides of the heating wire 9; connected; by providing protective elastic sheets 91 on both sides of the heating wire 9, the heating wire 9 is supported when there is gas flowing inside the air supply pipe 3, and the heating wire 9 is driven by the air flow, and hits the inside of the air supply pipe 3 The wall causes the problem of affecting the service life of the heating wire 9 and the air supply pipe 3.

[0039] When working, move the pressing seat 1 to the top of the substrate, and then place the copper foil on the top of the substrate. At this time, the pressing seat 1 can be pressed down, so that the elastic pressing plate 12 can squeeze the copper foil and the substrate. During the pressing process of the copper foil and the substrate, the middle part of the elastic pressing plate 12 will first con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com