Silage corn straw cutting machine

A technology of silage corn and cutting machine, which is applied in cutting equipment, agricultural machinery and implements, agriculture, etc., can solve the problems that the cutting effect cannot be achieved, the cutting and crushing of silage corn stalks is not meticulous, and the corn stalks cannot be crushed. Simple and practical, low maintenance difficulty, and the effect of controlling processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

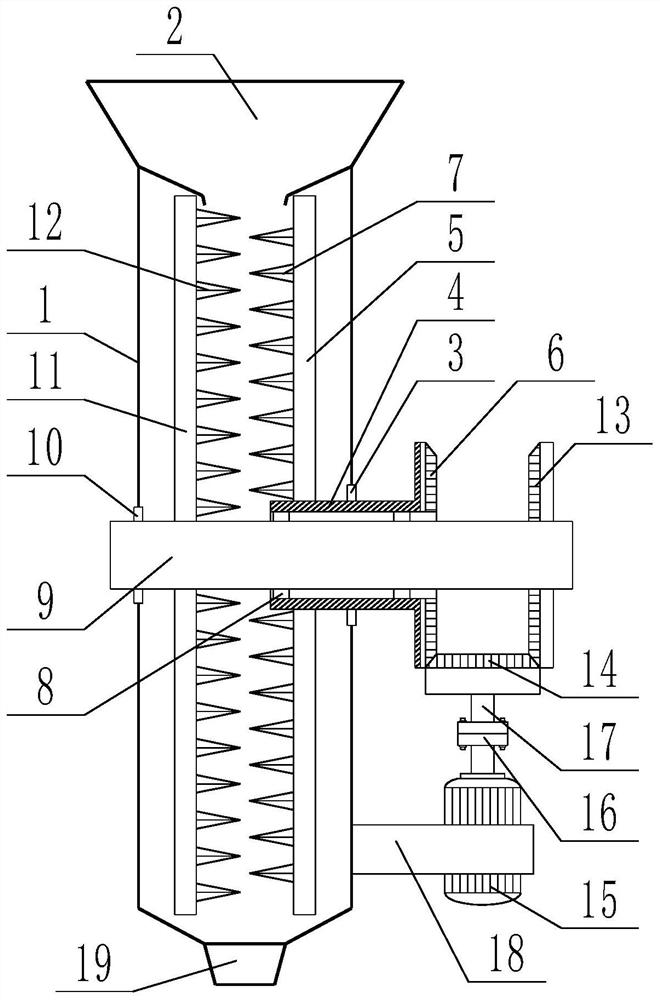

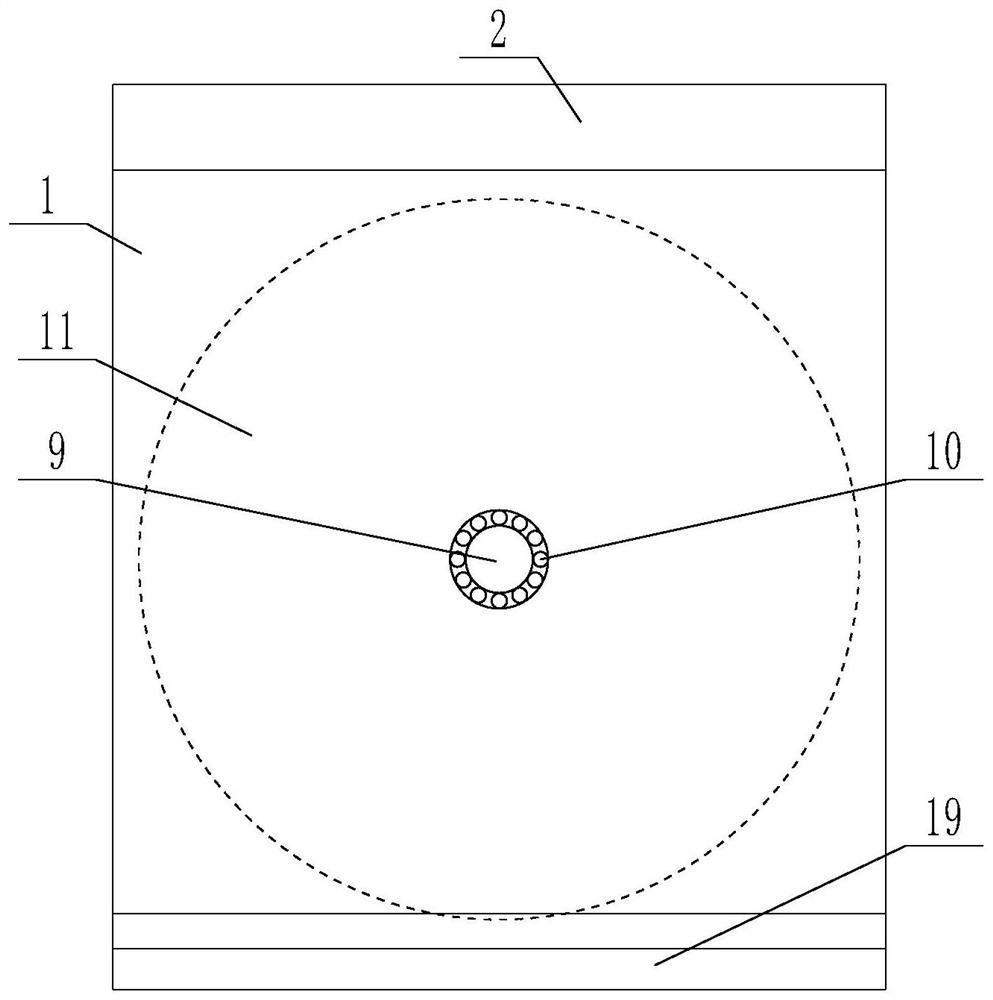

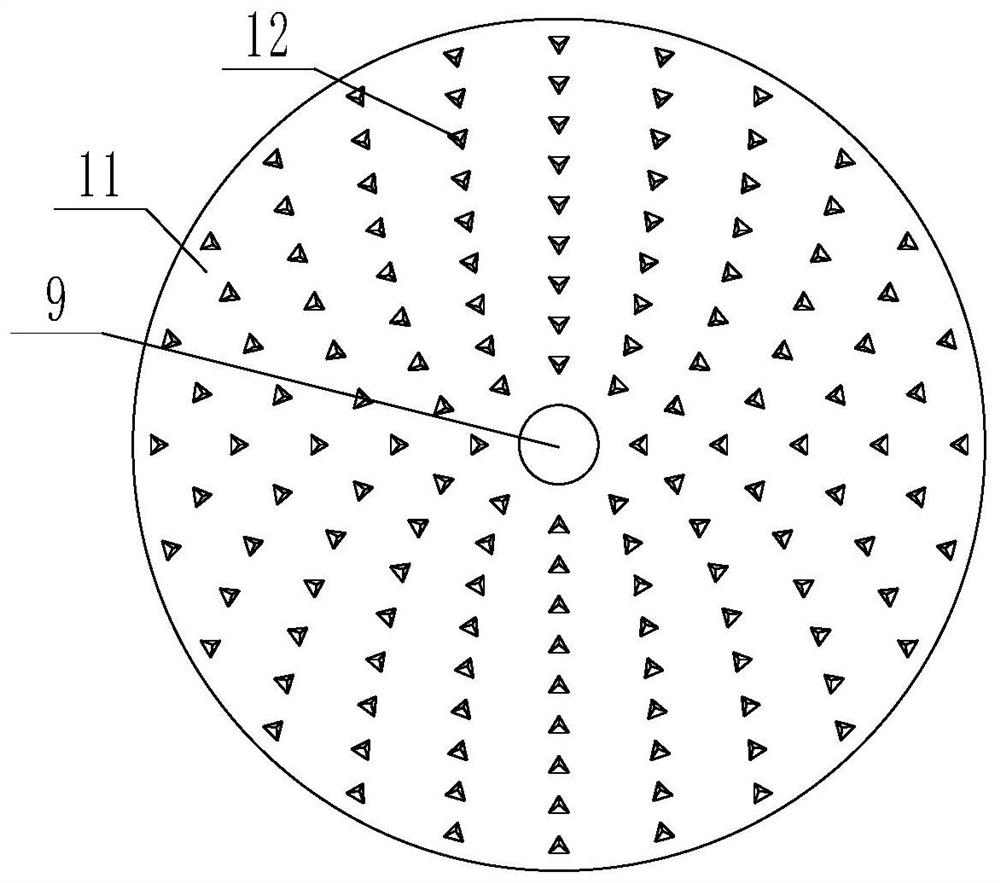

[0029] The inventive point of the present application is that a bearing one 3 is fixedly installed at the center of the right side of the box body, the bearing one communicates with the inner cavity of the box body, the bearing one is inserted with a rotating tube 4, and the rotating tube 4 is inserted into the bearing one. The length direction is perpendicular to the right side of the casing, one end of the rotating tube stretches into the inner cavity of the casing, the other end of the rotating tube is located on the right side of the casing, and a cutting disc-5 is fixedly installed on one end of the rotating tube. The cutting disc one is parallel to the right side of the casing, the other end of the rotating tube is fixedly installed with a helical gear-6, and the left side of the cutting disc one is fixedly installed with several crushing heads-7;

[0030] The invention of the present application is also that two inner bearings 8 are fixedly installed in the rotating tube...

Embodiment 2

[0039] In order to improve the cutting efficiency of the device for silage corn stalks, several crushing heads are arranged on the edge and the right side of the cutting disc one, and several crushing heads are arranged on the edge and the left side of the cutting disc two. Others are the same as in Example 1.

Embodiment 3

[0041]Increase the length of the crushing head so that the crushing head on the cutting disc 1 and the crushing head on the cutting disc 2 can intersect together, and at the same time adjust the distribution of the crushing heads on the cutting disc 1 and the cutting disc 2, and ensure that the cutting disc 1 and the cutting disc 2 When the cutting disc 2 rotates, the crushing head will not collide, and the fineness of straw crushing is improved through the cross crushing head structure. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com