Agricultural machinery surface cleaning equipment

A technology for surface cleaning and agricultural machinery, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems of difficult cleaning, laborious cleaning, low efficiency, etc. Efficient cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

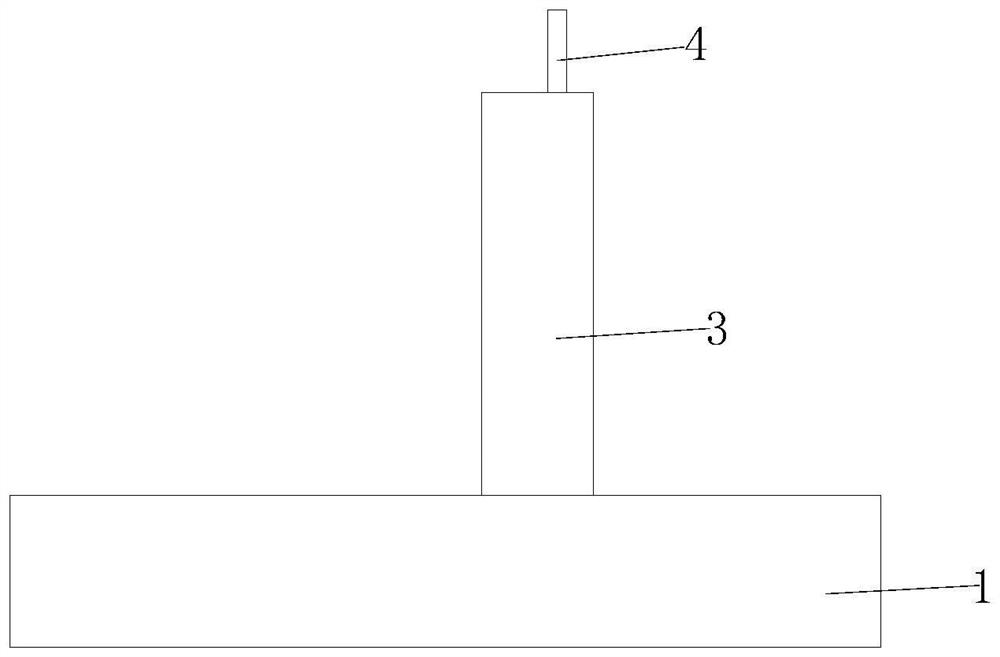

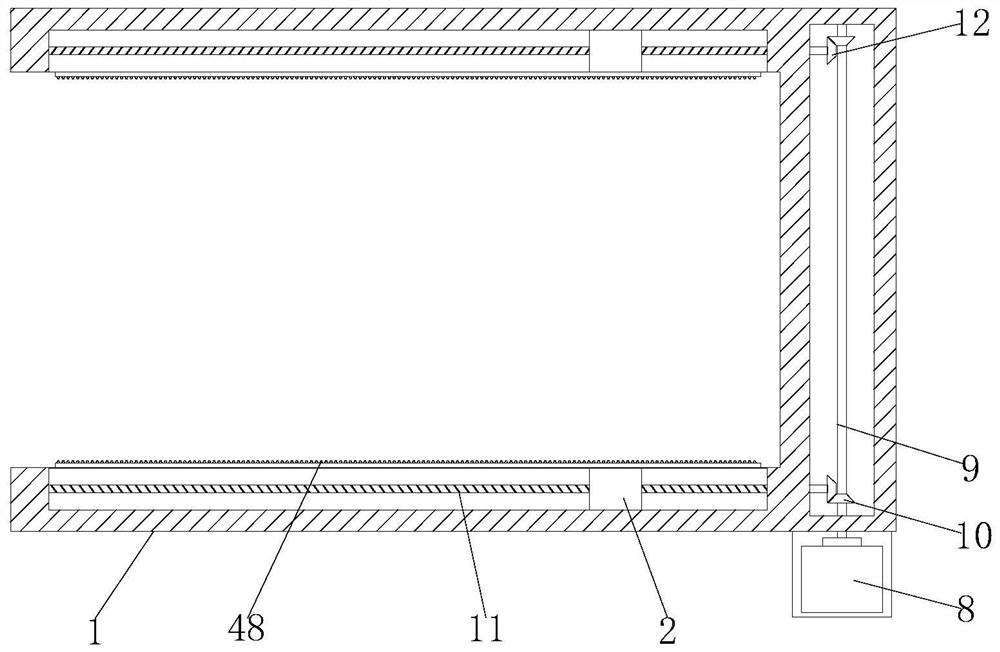

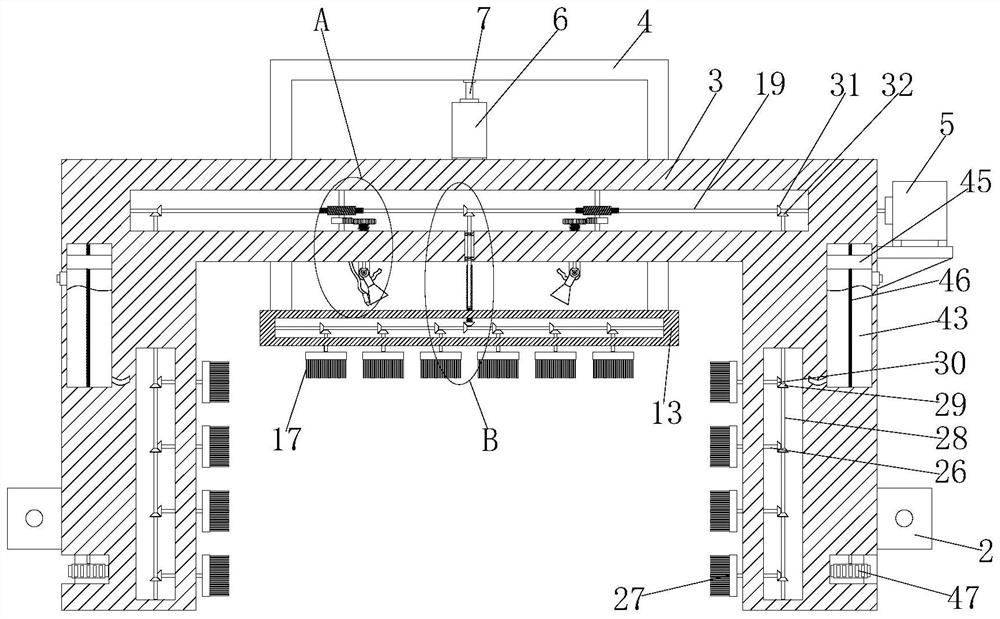

[0030] refer to Figure 1-6, a kind of agricultural machine surface cleaning equipment, comprises U-shaped frame base 1, and the inner wall of both sides of U-shaped frame base 1 is provided with chute, and slide block 2 is all slidably installed in two chute, two slide blocks 2 The sides close to each other are fixedly connected with the same gantry frame 3 by welding, and two sliding holes are opened on the gantry frame 3, and the same gantry frame 4 is slidably installed in the two sliding holes, and the bottom end of the gantry frame 4 is connected There is a first cleaning mechanism, and a second cleaning mechanism is arranged on the inner walls of both sides of the gantry frame body 3, and two water spraying mechanisms are arranged on the top inner wall of the gantry frame body 3, and cleaning liquid is arranged on the two water spraying mechanisms mechanism, the right side of the gantry frame body 3 is fixedly connected with a first motor plate by welding, and the top o...

Embodiment 2

[0042] The difference from Embodiment 1 is that the cleaning liquid mechanism includes a liquid storage chamber 43 arranged in the gantry frame 3 and a liquid outlet head 44 arranged on the spray head 33, the liquid outlet head 44 is connected with a connecting pipe, and the connecting pipe One end of one end is connected with the liquid storage chamber 43, and the rectangular piston plate 45 is slidingly installed in the liquid storage chamber 43, and the second threaded rod 46 is rotatably installed in the liquid storage chamber 43, and the second threaded hole is opened on the rectangular piston plate 45. Two threaded rods 46 are threadedly installed in the second threaded holes, grooves are provided on both sides of the gantry frame body 3, and the bottom end of the second threaded rods 46 extends into the grooves and is fixedly connected with a second rotating gear 47 , the inner wall of the U-shaped frame base is fixedly connected with a rack 48, the rack 48 is meshed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com