Lead frame die changing and cutting device

A lead frame and mold technology, applied in the field of lead frame mold switching devices, can solve the problems of lack of impact buffer, errors, and inability to quickly and automatically switch, and achieve the effect of improving processing efficiency and ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

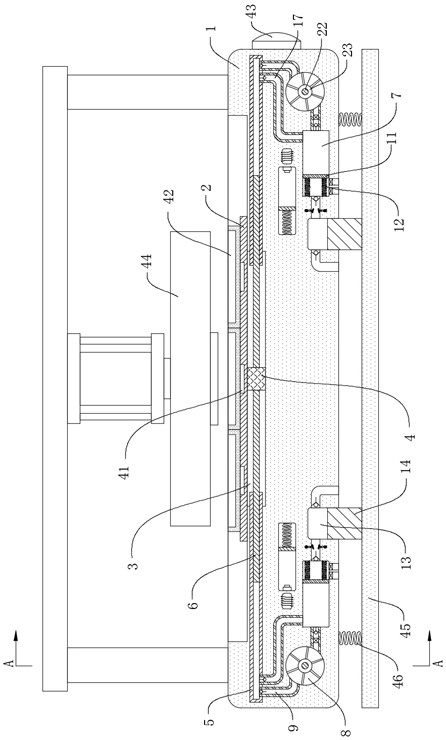

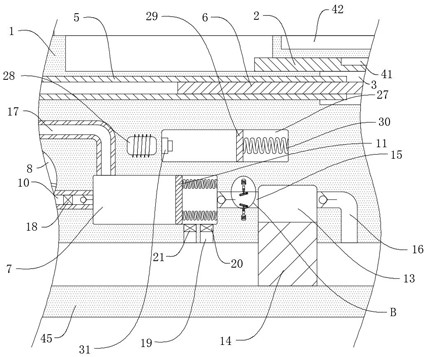

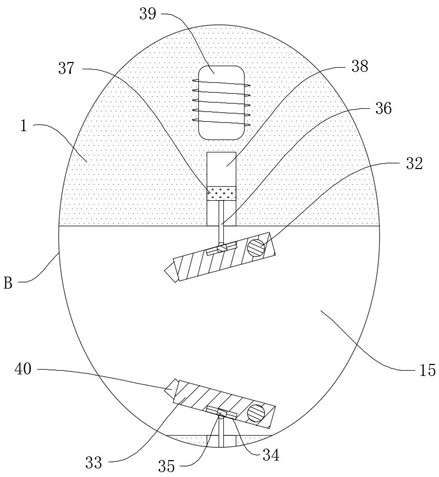

[0028] refer to Figure 1-6 , a lead frame mold switching device, a main body seat 1, a sliding plate 2 is slidably connected to the upper surface of the main body seat 1, and three stamping dies 42 are detachably connected to the upper surface of the sliding plate 2, and the three stamping dies 42 are detachably connected by bolts , so that the mold can be freely replaced according to the needs, and the switch between different molds is completed. The upper surface of the main body seat 1 is provided with a stamping device 44. The stamping device 44 is composed of a hydraulic cylinder and a stamping head. It is a prior art and will not be repeated here. , the main body seat 1 is provided with a quick switching mechanism;

[0029]The quick switching mechanism includes a sliding groove 3 provided in the main body seat 1, a slider 4 is slidably connected in the sliding groove 3, the slider 4 is fixedly connected with the lower surface of the sliding plate 2, and two sliding bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com