Automatic production equipment and production method for environment-friendly paper straws

An automatic production and straw technology, applied in metal processing, etc., can solve the problems of increasing equipment motion load and motion accuracy, increasing equipment cost and production difficulty, increasing working hours and workload, etc., to reduce the need for manual transfer and arrangement Work process, reduce motion impact, reduce loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

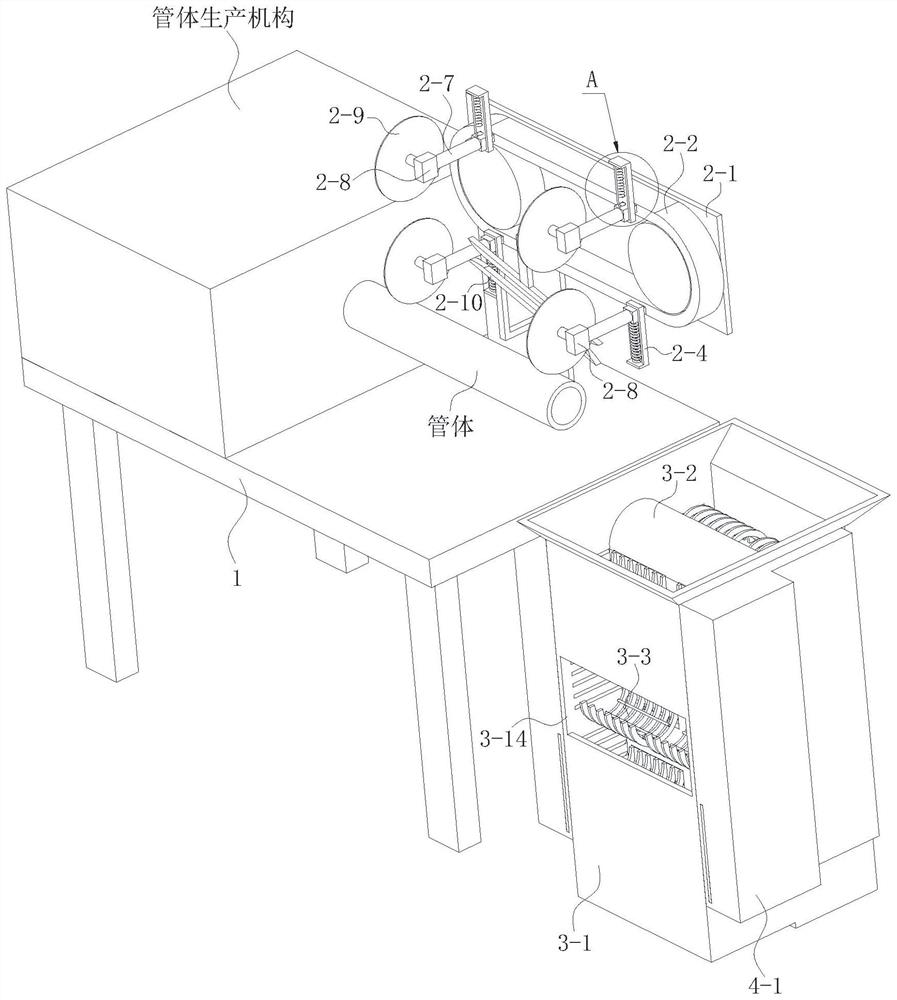

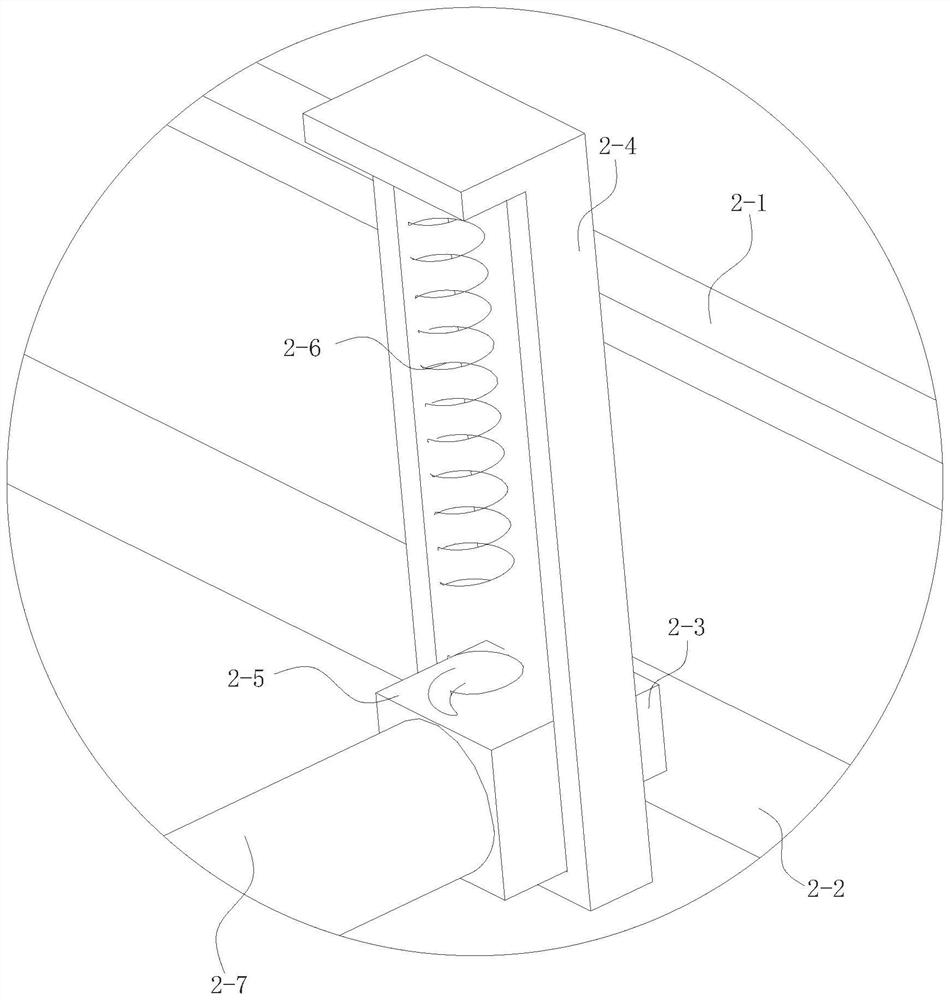

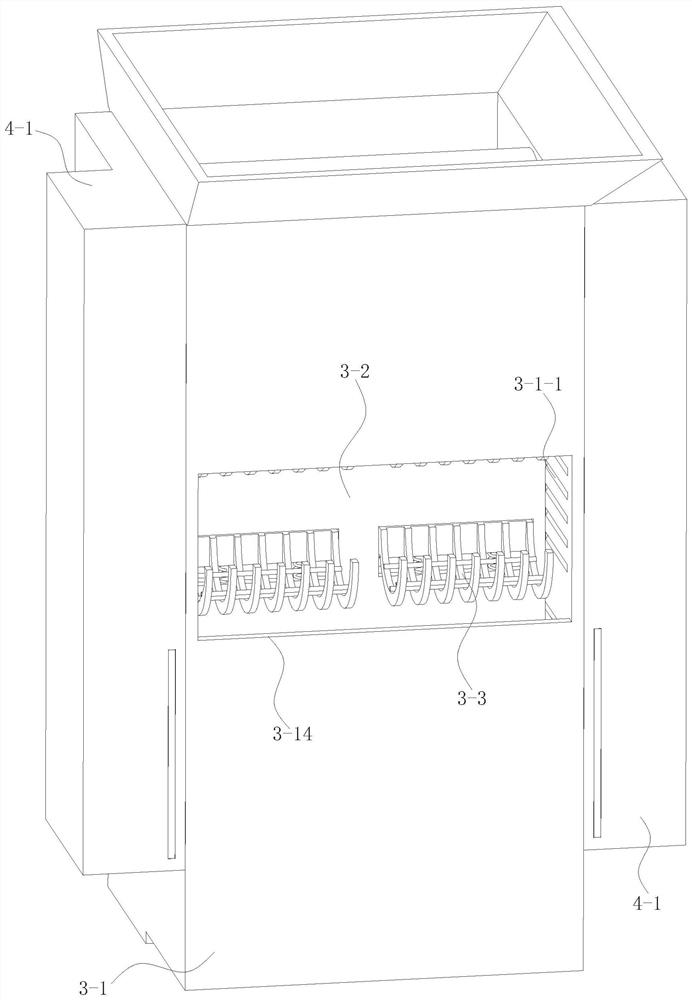

[0037] see Figure 1-12 , the present invention provides a technical solution: an automatic production equipment for environmentally friendly paper straws, including a pipe body production mechanism, an installation platform 1, a segmentation mechanism and a cutting mechanism; side, the segmentation mechanism is fixedly arranged on the right side of the upper end of the installation platform 1, and the cutting mechanism is arranged on the right side of the installation platform 1; the pipe body production mechanism is used to produce the pipe body and transport the pipe body to the right, the The segmenting mechanism quickly segments the tube body by rotating the cutter along the transporting direction of the tube body, and the cutting mechanism is used to align and cut the straw segments into straws.

[0038] The segmenting mechanism quickly segments the tube body by rotating the cutter along the transport direction of the tube body, so that the tool can segment the tube body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com