High-precision intelligent trepanning equipment for processing polyester leather bag

A high-precision, coated technology, applied in metal processing, mechanical equipment, recycling technology, etc., can solve the problems of slow work efficiency, waste of manpower, etc., to facilitate replacement and maintenance, improve punching efficiency, and prevent shaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

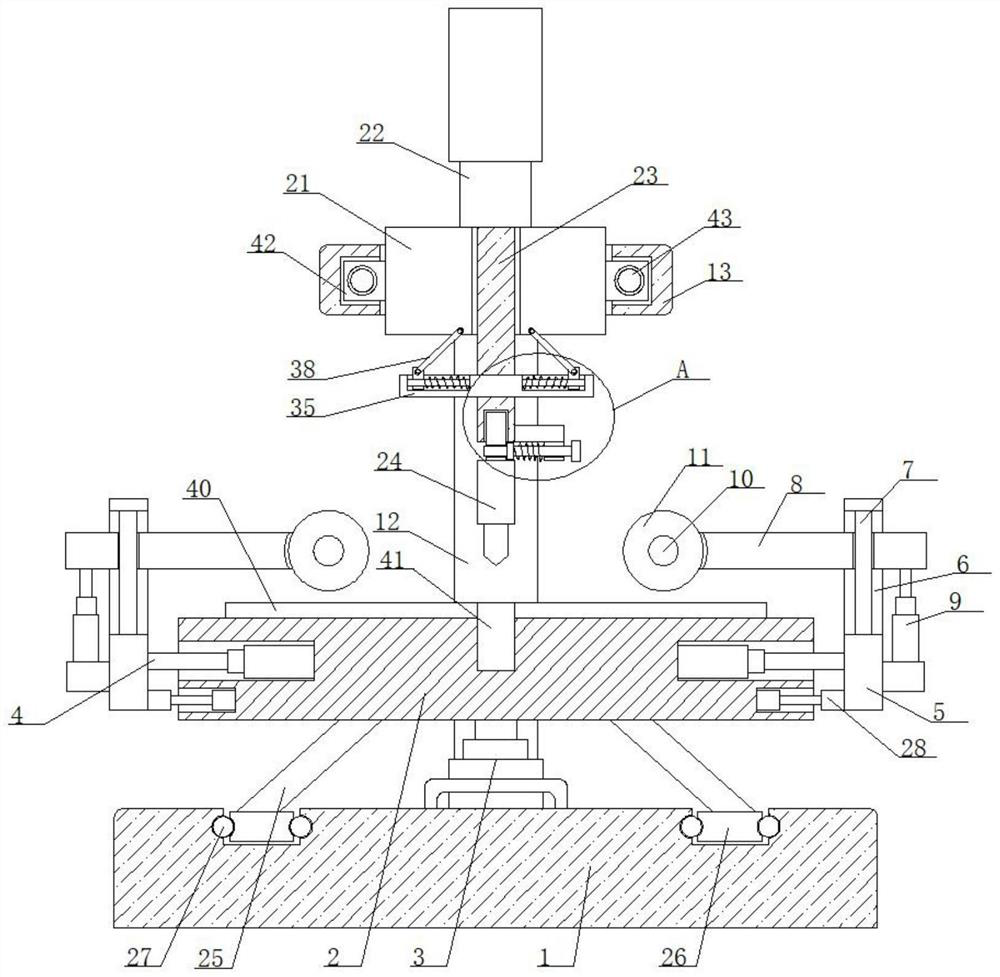

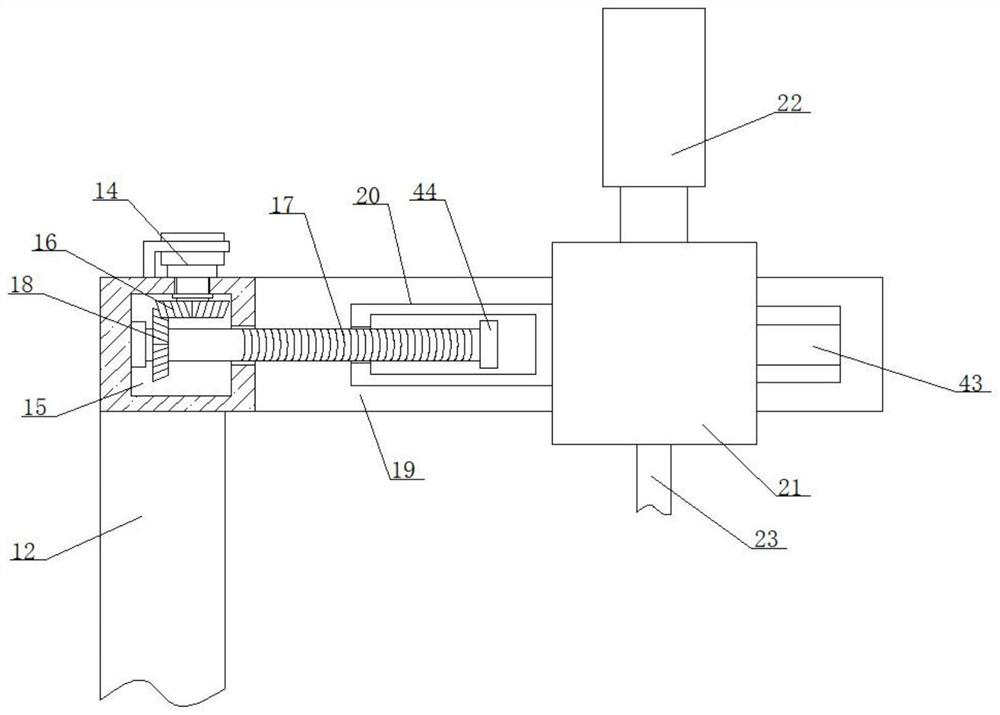

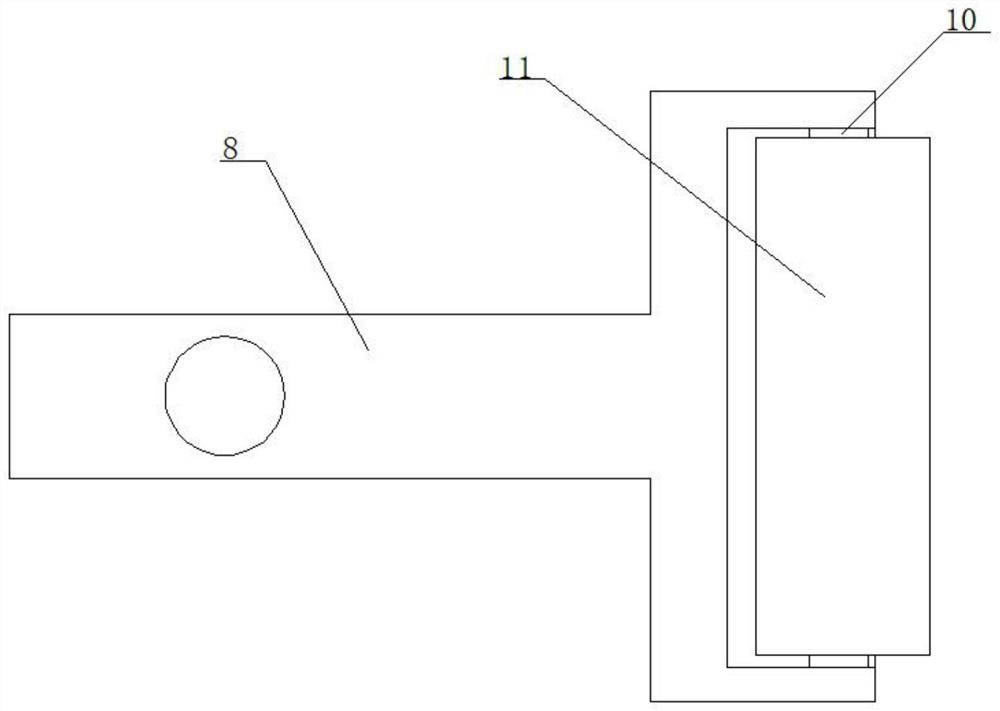

[0031] refer to Figure 1-4 , an intelligent perforating device for processing high-precision coated fiber leather bags, including a mounting base 1, a mounting plate 2, a pressing mechanism, an adjusting mechanism and a punching mechanism, the top of the mounting base 1 is fixedly connected with a first motor 3, Used to drive the mounting plate 2 to rotate, the output end of the first motor 3 is fixedly connected to the bottom of the mounting plate 2, and the bottom of the mounting plate 2 is fixedly connected to a support mechanism for supporting the mounting plate 2;

[0032] In this embodiment, the top of the mounting seat 1 is provided with an annular slide rail corresponding to the support mechanism, the support mechanism includes a slanting bar 25 for supporting the mounting plate 2, and the bottom of the slanting bar 25 is fixedly connected to the slider 26 to prevent the slanting Rod 25 shakes, and a plurality of steel balls 27 are slidably connected in the annular sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com