Multi-sandwich component composite board device of transportation tool

A technology for transportation tools and composite panels, applied in the field of composite panels, can solve problems such as excessive stretching, damage to composite panels, and impact on the bearing capacity of composite panels, so as to avoid poor bearing capacity, enhance elasticity, and achieve better bearing effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

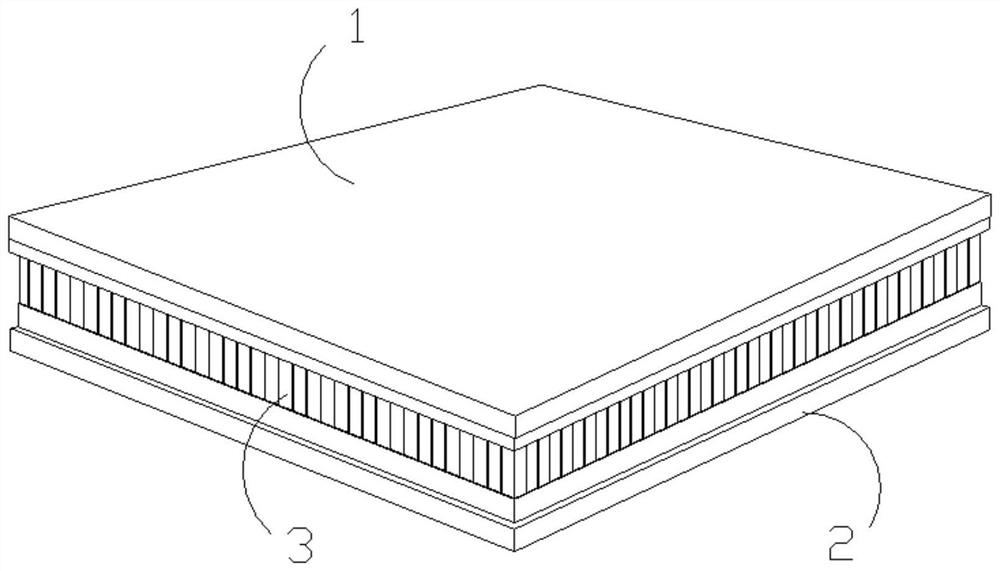

[0041] Such as Figure 1-5 As shown, a multi-sandwich component composite board device for a transportation tool according to the present invention includes an upper layer board 1, a bottom board 2, and a sandwich composite part 3, and the upper end of the sandwich composite part 3 is connected to the upper layer board 1 , the bottom plate 2 is connected under the sandwich composite part 3;

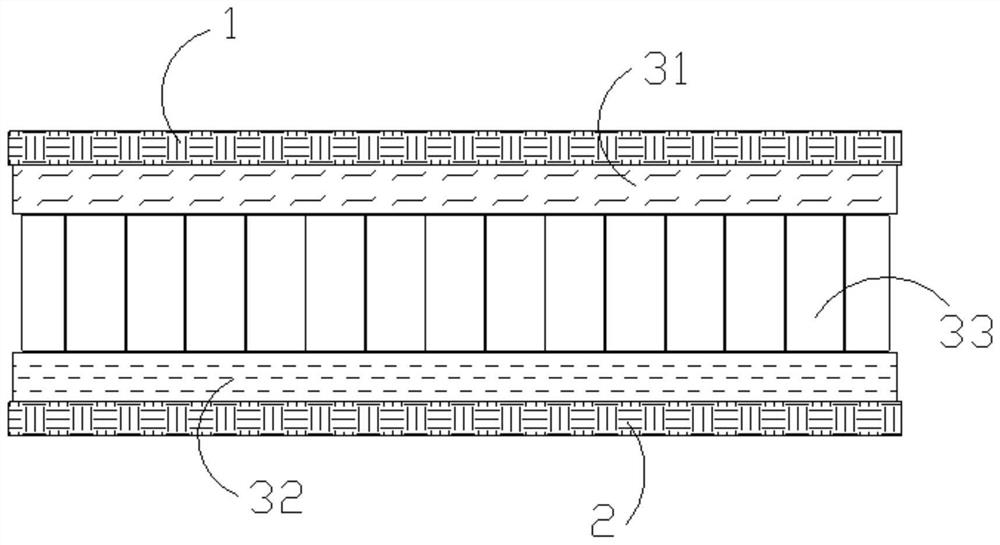

[0042] The sandwich composite part 3 is provided with a heat conduction layer 31, a force layer 32, and a sandwich layer 33. The upper end of the heat conduction layer 31 is connected with an upper plate 1, and the bottom plate 2 is connected below the force layer 32. The heat conducting layer 31 is connected above the sandwich layer 33, and the force layer 32 is connected below the sandwich layer 33;

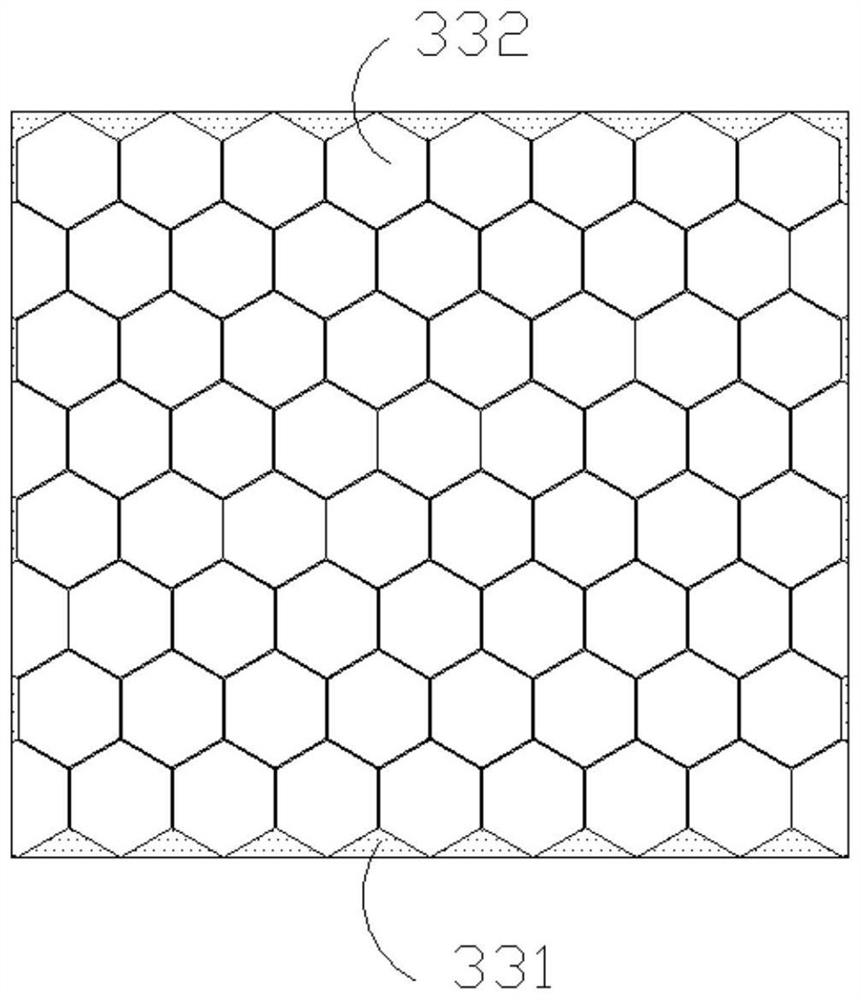

[0043] Wherein, the sandwich layer 33 is provided with a structural panel 331 and a cell 332, the cell 332 and the structural panel 331 are integrated and arranged through, and the struct...

Embodiment 2

[0048] Such as Figure 6-7 As shown: wherein, the heat conduction layer 31 is provided with a frame plate q1, a heat conduction sheet q2, and a flat surface q3. There is a heat conduction sheet q2, and the heat conduction sheet q2 is a circular ceramic material block structure, which has thermal conductivity, the bonding degree of the frame plate q1 is good, and the bonding degree between the structural layers of the frame plate q1 is good , so that its top and bottom can be better adhered to foreign objects, so that the heat conduction sheet q2 has a heat conduction effect on the sandwich layer 33;

[0049] Wherein, the force layer 32 is provided with a bonding plate w1, a force plate w2, and a buffer layer w3, the bonding plate w1 is fixed under the force plate w2, and the buffer layer w3 is located between the bonding plate w1 and the buffer layer w3. Between the load plates w2, the load plate w2 is a soft resin plate-like structure with a certain thickness, the buffer lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com