Workpiece transposition manipulator of hydraulic stretching machine

A stretching machine and manipulator technology, applied in the field of hydraulic stretching machines, can solve problems such as increased manpower input, inability to clamp workpieces, and low work efficiency, and achieve the effects of improving work efficiency, saving manpower input, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

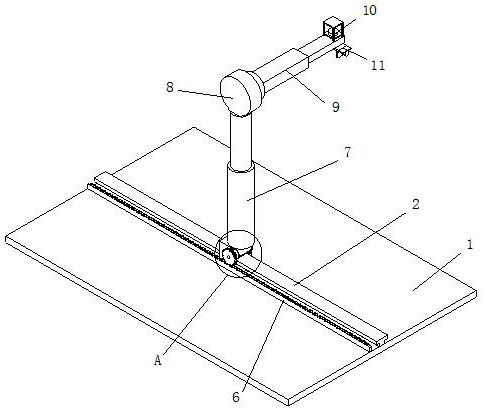

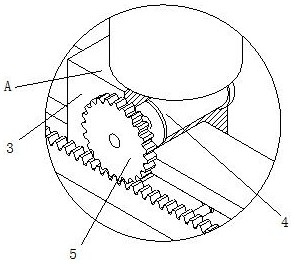

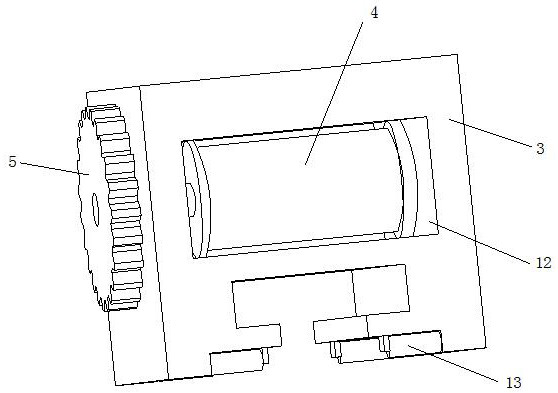

[0030] refer to Figure 1-6 , a hydraulic stretching machine workpiece transposition manipulator provided by the present invention: includes a bottom plate 1, the top of the bottom plate 1 is provided with a mounting seat 3, the top of the mounting seat 3 is fixedly connected with a first telescopic rod 7, the first telescopic rod 7 The top is fixedly connected with a swivel base 8, the right end of the swivel base 8 is fixedly connected with a second telescopic rod 9, the right end of the second telescopic rod 9 is provided with a steering mechanism 10, the steering mechanism 10 includes a mounting frame 14, and the internal sliding connection of the mounting frame 14 Limit block 15, the inside of limit block 15 is fixedly connected with second motor 16, the bottom of second motor 16 is fixedly connected with rotating shaft 17, and the bottom of rotating shaft 17 is fixedly connected with clamping device 11, and clamping device 11 and second There is a gap between the telesco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com