Control method for reducing gas consumption under long coking time of coke oven

A technology of coking time and control method, applied in coke ovens, furnace safety devices, petroleum industry, etc., can solve the problems of non-absorbing heat, overheating coke, wasting gas, etc., achieving high labor efficiency, little influence of furnace temperature, and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

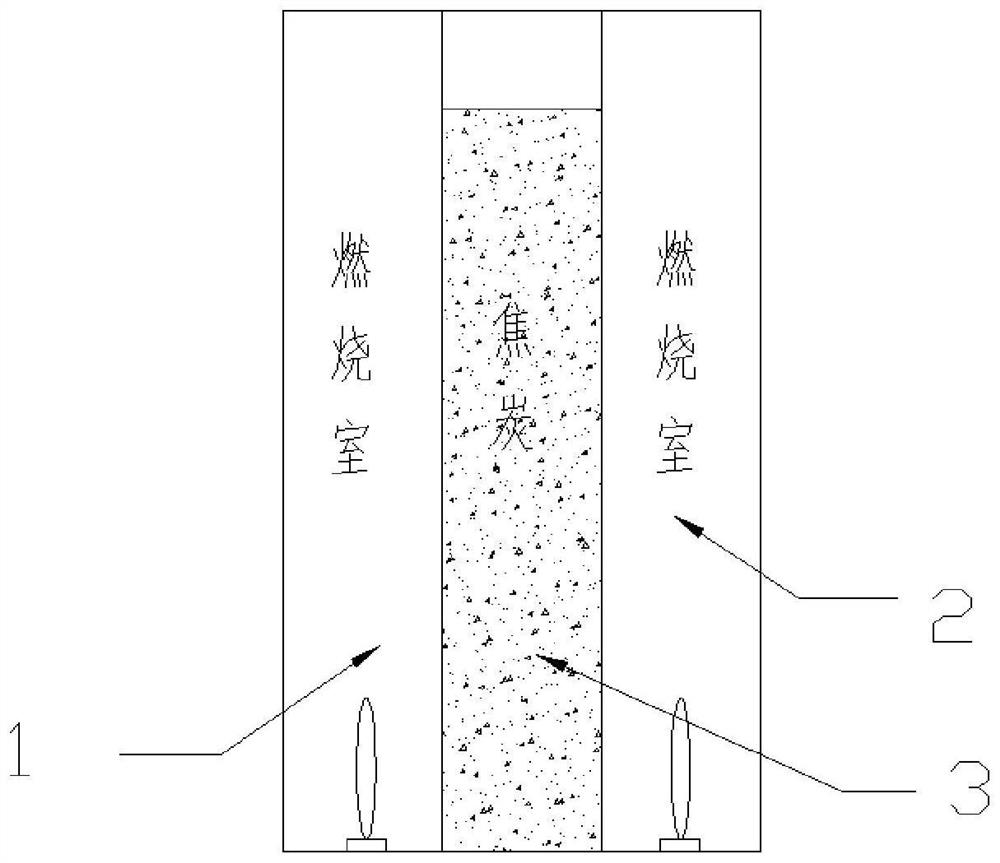

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0018] Such as figure 1 Shown, technical scheme of the present invention is:

[0019] A control method for reducing gas consumption under long coking time of coke ovens, based on the coke oven designed by China Metallurgical Coking Resistance Engineering Technology Co., Ltd., the model of the coke oven is JN60-6; 4 hours before the coke is pushed in the carbonization chamber that needs temperature control Start the operation of temperature control and gas saving to reduce the heat supply of the carbonization chamber. The specific operation method is: close 1 / 2 of the gas adjustment cock of the corresponding combustion chamber of the carbonization chamber, close 1 / 3 of the gas adjustment cock of the adjacent combustion chamber, and close Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com