Supercritical extraction system for plant essential oil

A supercritical extraction and plant essential oil technology, applied in the field of separation equipment, can solve the problems of increased cost of plant essential oil extraction, cumbersome process, and reduced efficiency and effect, and achieve the effects of uniform force, improved extraction effect, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

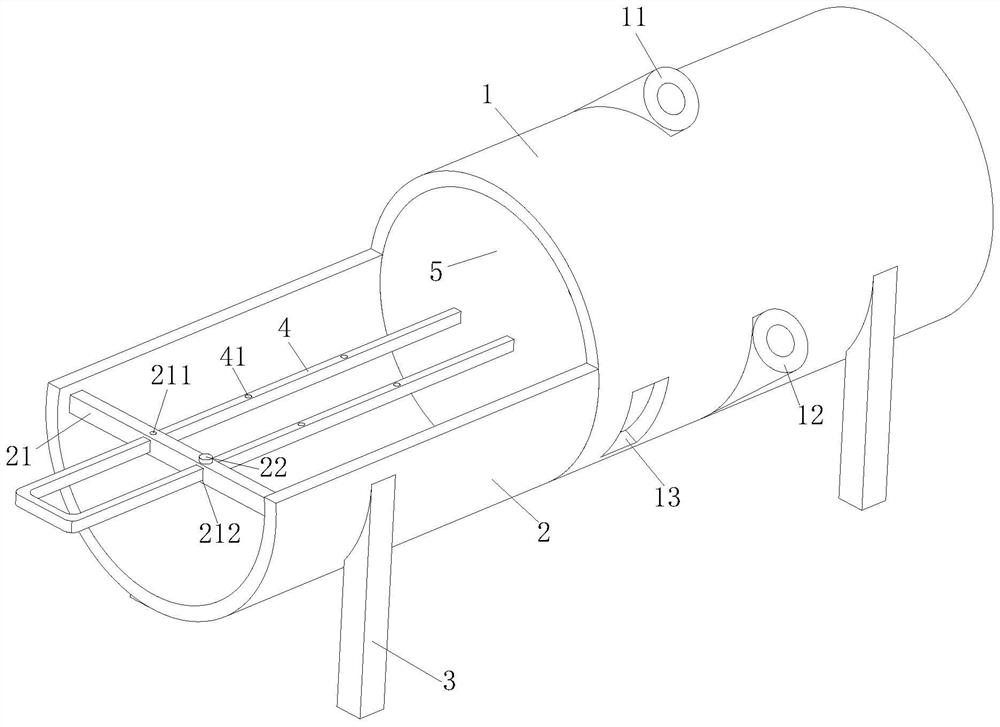

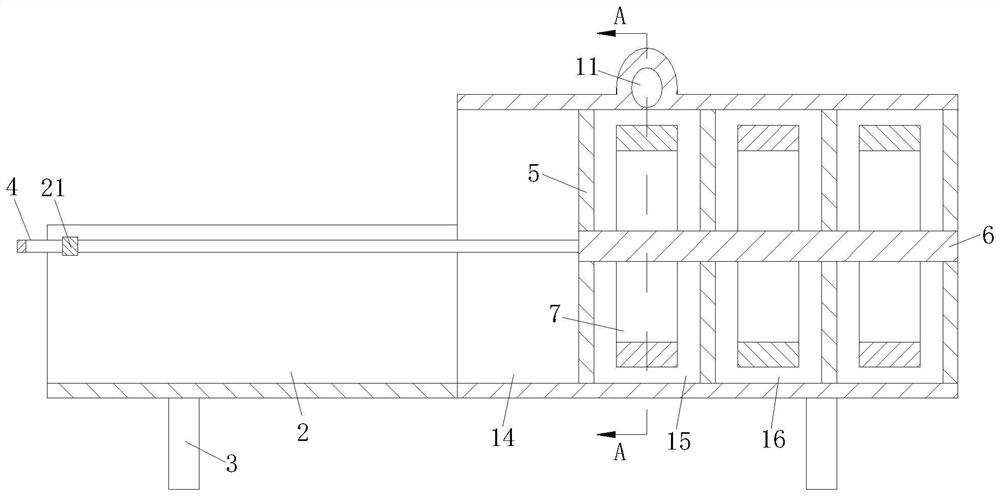

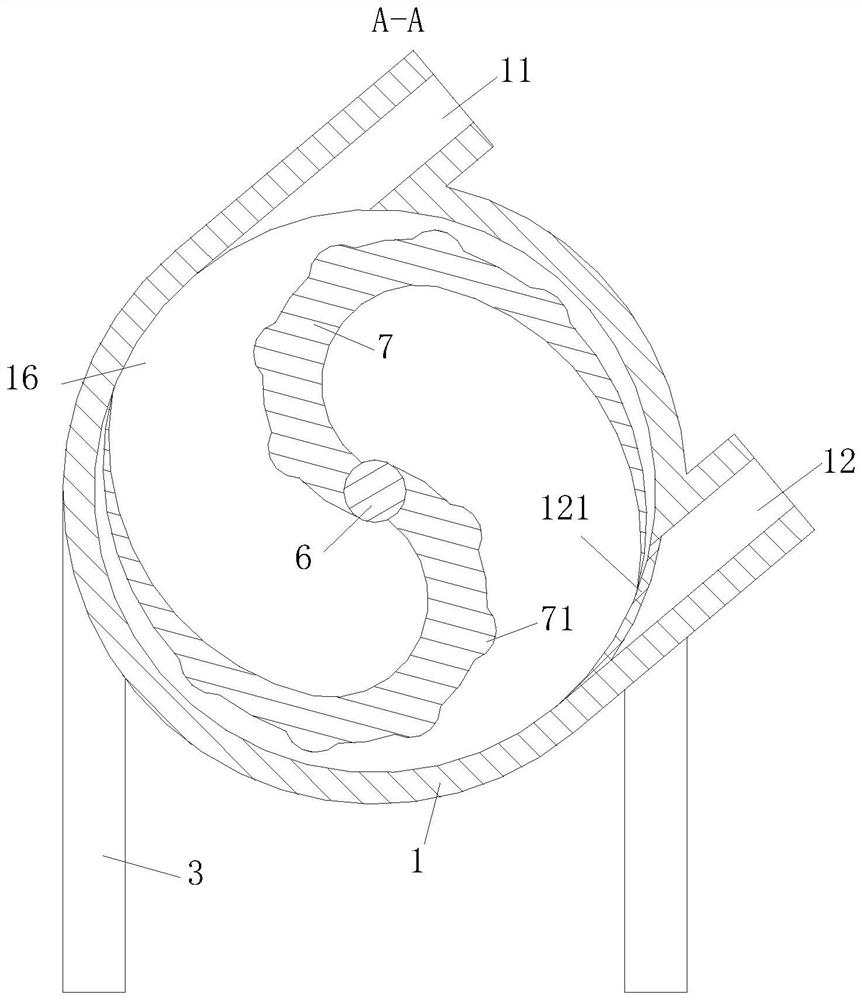

[0032] A plant essential oil supercritical extraction system, comprising an extraction cylinder 1 and a leg 3; the extraction cylinder 1 is provided with a liquid inlet 11, a liquid outlet 12 and a discharge port 13; the leg 3 is fixedly connected to the On the side wall of the extraction cylinder 1;

[0033] Extraction cylinder 1, said extraction cylinder 1 can carry out plant essential oil extraction to plant body through the impact of carbon dioxide fluid;

[0034] A partition 5, the partition 5 is in sliding and sealing connection with the extraction cylinder 1, and one end of the partition 5 is fixedly connected with a push-pull rod 4;

[0035] When working, but the plant itself will volatilize part of the essential oil during the crushing process of the crusher, and it is difficult to collect the volatilized plant essential oil, resulting in a part of the essential oil being wasted during the crushing process. Therefore, the more expensive plant essential oil If a large...

Embodiment 2

[0047] A plant essential oil supercritical extraction system, comprising an extraction cylinder 1 and a leg 3; the extraction cylinder 1 is provided with a liquid inlet 11, a liquid outlet 12 and a discharge port 13; the leg 3 is fixedly connected to the On the side wall of the extraction cylinder 1;

[0048] Extraction cylinder 1, said extraction cylinder 1 can carry out plant essential oil extraction to plant body through the impact of carbon dioxide fluid;

[0049] A partition 5, the partition 5 is in sliding and sealing connection with the extraction cylinder 1, and one end of the partition 5 is fixedly connected with a push-pull rod 4;

[0050] When working, but the plant itself will volatilize part of the essential oil during the crushing process of the crusher, and it is difficult to collect the volatilized plant essential oil, resulting in a part of the essential oil being wasted during the crushing process. Therefore, the more expensive plant essential oil If a large...

Embodiment 3

[0059] A plant essential oil supercritical extraction system, comprising an extraction cylinder 1 and a leg 3; the extraction cylinder 1 is provided with a liquid inlet 11, a liquid outlet 12 and a discharge port 13; the leg 3 is fixedly connected to the On the side wall of the extraction cylinder 1;

[0060] Extraction cylinder 1, said extraction cylinder 1 can carry out plant essential oil extraction to plant body through the impact of carbon dioxide fluid;

[0061] A partition 5, the partition 5 is in sliding and sealing connection with the extraction cylinder 1, and one end of the partition 5 is fixedly connected with a push-pull rod 4;

[0062] When working, but the plant itself will volatilize part of the essential oil during the crushing process of the crusher, and it is difficult to collect the volatilized plant essential oil, resulting in a part of the essential oil being wasted during the crushing process. Therefore, the more expensive plant essential oil If a large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com