Preparation method of lycopene particles based on subcritical extraction and supercritical granulation combined process

A technology of lycopene and combined process, applied in the direction of extraction and purification/separation, chemical instruments and methods, hydrocarbons, etc., can solve the problems of inability to be absorbed by the human body, poor solubility, etc., and achieve the goal of improving bioavailability and efficient extraction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

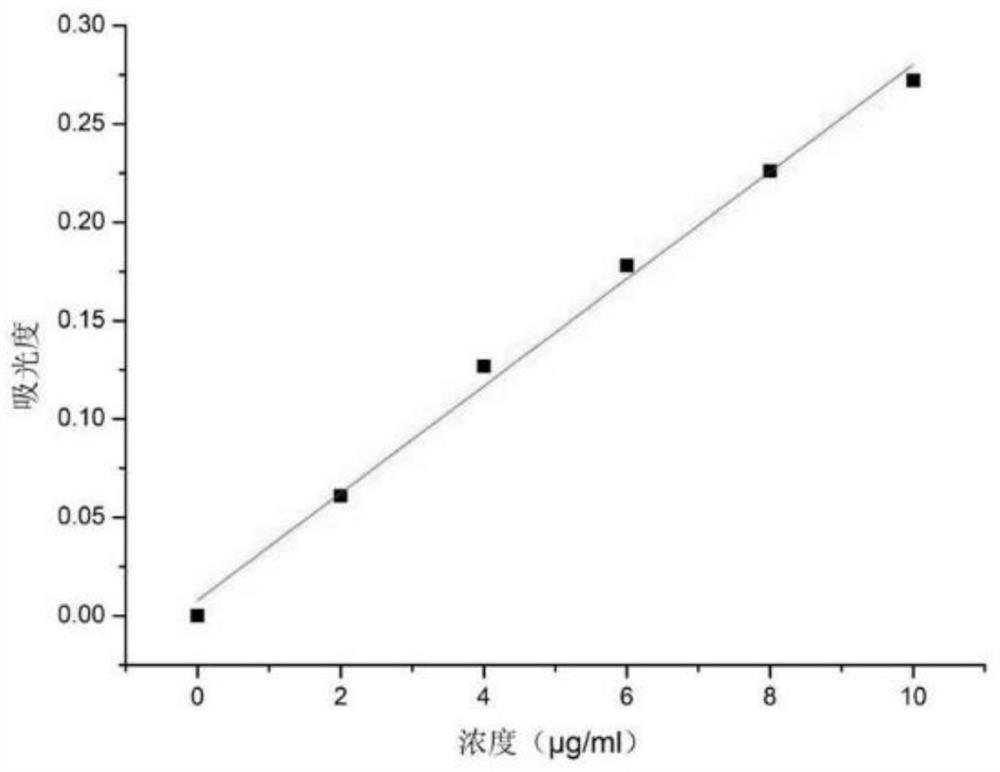

[0030] Accurately weigh 66g of the pretreated tomato, put it into the extraction tank, add 1600mL of pure water, seal the tank, turn on the agitator, adjust to 120r / min, turn on the heater, heat to 110°C and pressurize, when When the pressure gauge reaches 1 MPa, stop pressurizing, and continue heating and extracting at 110°C for 30 minutes. After the extraction, turn on the circulation pump, cool the steam released from the extraction tank with cooling water, and then further cool down after passing through the low-temperature cooling tank, and finally the extract enters the receiving tank, and the extraction rate is 342.4 μg / g measured by ultraviolet spectrophotometry.

Embodiment 2

[0032]Accurately weigh 66g of the pretreated tomato, put it into the extraction tank, add 1600mL of pure water, seal the tank, turn on the agitator, adjust to 120r / min, turn on the heater, heat to 120°C and pressurize, when When the pressure gauge reaches 1 MPa, stop pressurizing, and continue heating and extracting at 120°C for 30 minutes. After the extraction is finished, turn on the circulation pump, cool the steam released from the extraction tank with cooling water, and then further cool down after passing through the low-temperature cooling tank, and finally the extract enters the receiving tank, and the extraction rate is 848.0 μg / g measured by ultraviolet spectrophotometry.

Embodiment 3

[0034] Accurately weigh 66g of the pretreated tomato, put it into the extraction tank, add 1600mL of pure water, seal the tank, turn on the agitator, adjust to 120r / min, turn on the heater, heat to 130°C and pressurize, when After the pressure gauge reached 1 MPa, the pressurization was stopped, and the extraction was continued at 130°C for 30 minutes. After the extraction, turn on the circulation pump, cool the steam released from the extraction tank with cooling water, and then cool it further after passing through a low-temperature cooling tank. Finally, the extract enters the receiving tank. The extraction rate is 689.6 μg / g measured by ultraviolet spectrophotometry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com