Printing and dyeing singeing machine

A technology of singeing machine and pressing roller mechanism, which is applied to singeing, textile and paper making, fabric surface trimming, etc. The effect of saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

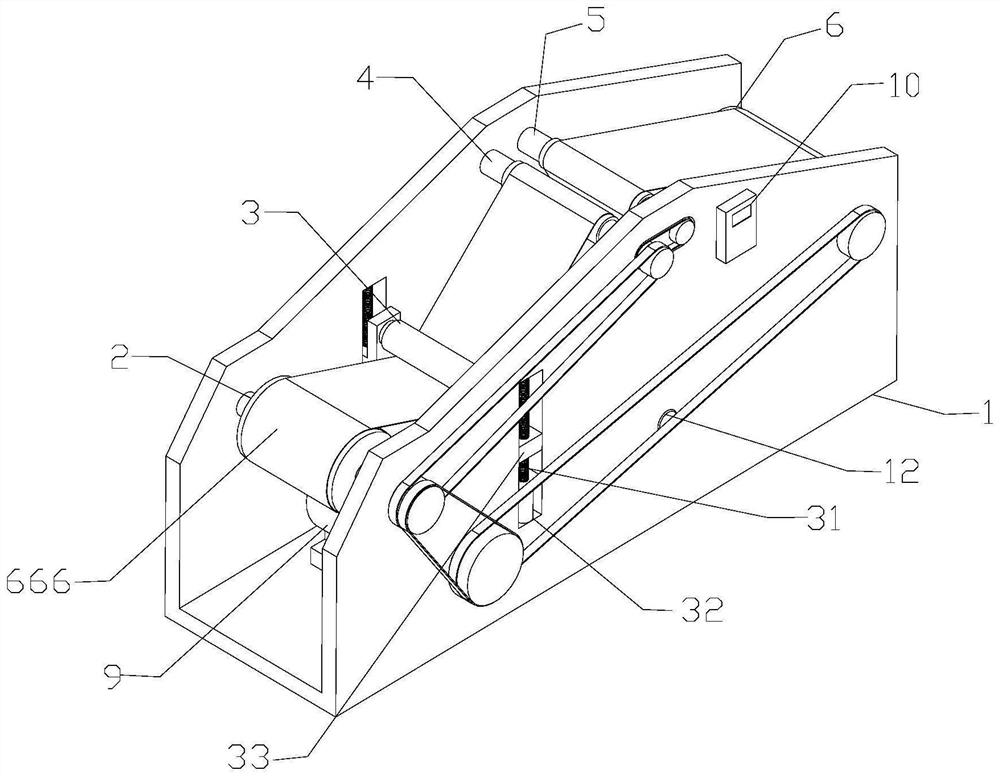

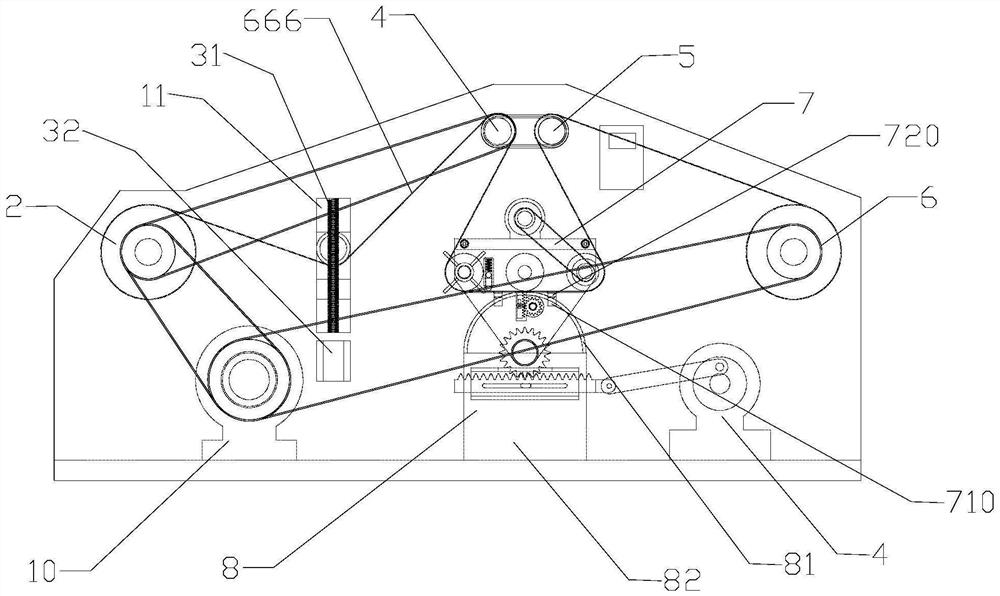

[0030] In order to understand the present invention better, below in conjunction with appendix figure 1 to attach Figure 13 To explain the embodiment of the present invention in detail.

[0031] It should be noted that the "front, back, left, right, up, down" directions mentioned in the article are all in the attached figure 1 The "front, back, left, right, up, down" direction in the

[0032] Printing and dyeing singeing machine, including frame 1, cloth feeding roller 2, regulating roller mechanism 3, fabric supporting roller Ⅰ4, fabric supporting roller Ⅱ5, cloth receiving roller 6, swinging pressure roller mechanism 7, singeing mechanism 8, drive motor 9 and control device 10.

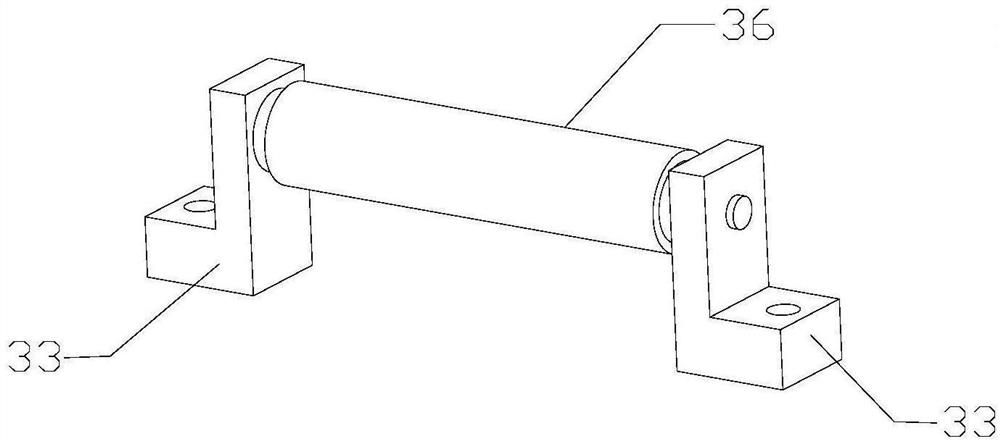

[0033] The inside of the frame 1 is rotatably provided with a feed roller 2, a cloth support roller I4, a cloth support roller II5 and a cloth receiving roller 6 from left to right. The front and rear ends of the frame 1 are provided with an adjustment roller mechanism placement groove 11 betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com