Rock carbonate oil reservoir flow channel adjustment construction process

A construction technology and carbonate rock technology, applied in the fields of production fluids, wellbore/well components, sealing/packing, etc., can solve problems such as inability to inject, and achieve the effect of safe and effective construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

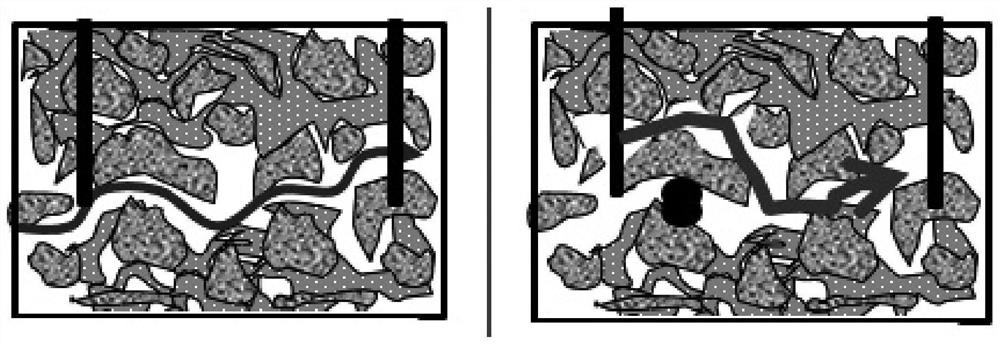

Method used

Image

Examples

experiment example 1

[0121] Experimental example 1. Construction of channel adjustment of a water injection well A in District 7 of Tahe River

[0122] ① Measure water absorption

[0123] Displacement 1.0m3 / min, maximum oil pressure 23.4MPa, in line with safety construction requirements

[0124] ②Pressure test

[0125] Install the flow channel to adjust the ground construction equipment, pressurize to 32MPa and keep for 30min to measure the pressure drop. If the pressure drop is less than 0.5MPa, the pressure drop is qualified.

[0126] ③ trial injection

[0127] The volume of the wellbore is 25 cubic meters, and the volume of the open hole section is 0.82 cubic meters. During the test injection, a total of 20 cubic meters of low-density particles with a concentration of 2% were pumped at the designed maximum displacement of 0.5 cubic meters per minute, and 75 cubic meters of oilfield water was pushed back. The whole process pressure did not exceed 3.9 MPa.

[0128] ④ Flow regulating slug inje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com