Range hood

A technology for range hoods and fume collecting hoods, which is applied in the direction of removing oil fumes, household stoves/stoves, and heating methods. It can solve the problems of low efficiency and high labor intensity of range hoods, and achieve improved assembly efficiency, safety and compact type effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

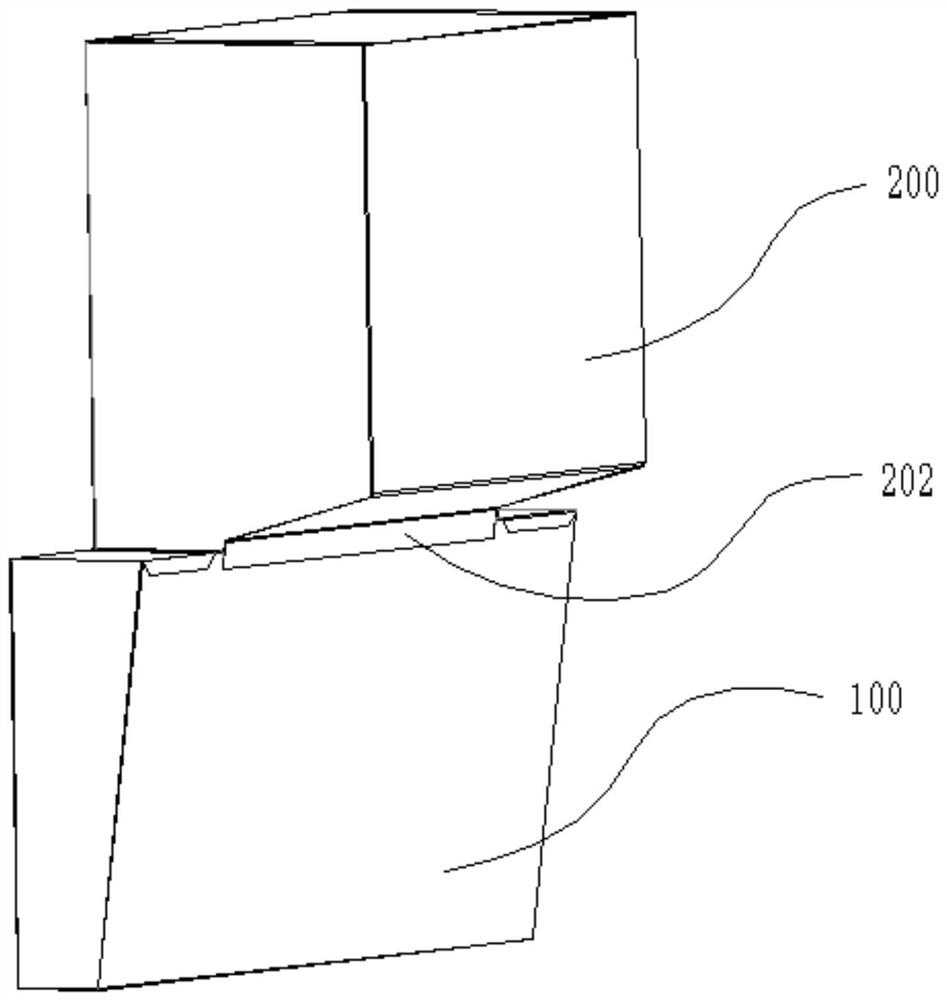

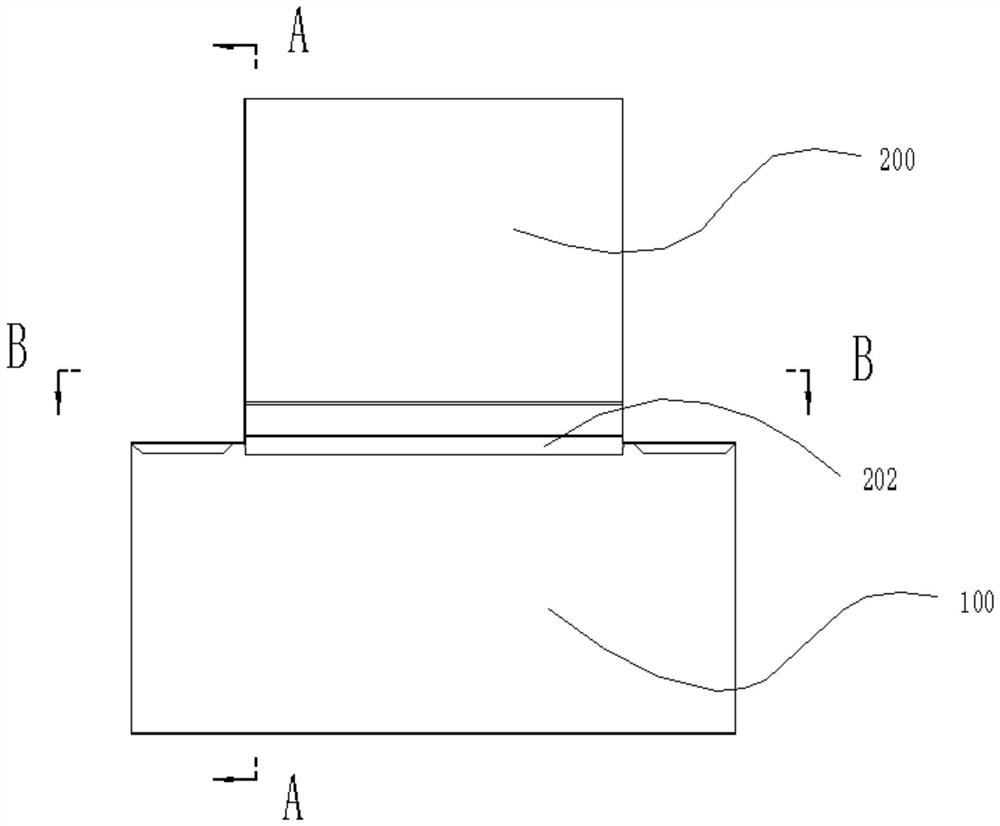

[0050] Such as Figure 1 to Figure 9 As shown, in the embodiment of the present invention, a range hood is introduced, which includes a fume collecting hood 100 and a main box 200 , and the main box 200 is installed above the fume collecting hood 100 .

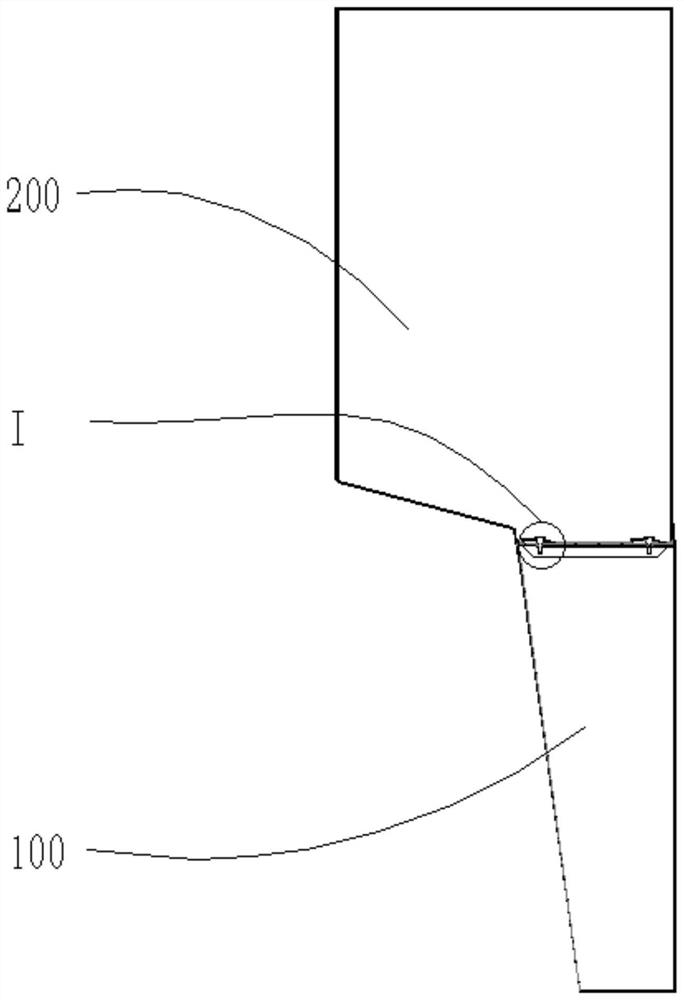

[0051] Such as image 3As shown, in this embodiment, a connecting structure is provided between the fume collecting hood 100 and the main box 200 . The connecting structure includes a clamping part 101 provided on the smoke collecting hood 100 and a boss 201 provided on the main box 200. between installations.

[0052] Such as Figure 8 and Figure 9 As shown, in this embodiment, the boss 201 is arranged at the bottom of the main box 200 , and the engaging portion 101 is arranged at the top of the smoke collecting hood 100 . Specifically, the boss 201 protrudes from the bottom of the main box 200 to the inside of the main box 200, and one side of the boss 201 is provided with a slope 2011, and the slope 2011 is provided w...

Embodiment 2

[0070] In this embodiment, the main box 200 has a double-layer structure, the outer wall of the side plate of the inner structure is spaced apart from the inner wall of the side plate of the outer structure, and the lower end of the side plate of the outer structure is provided with an inwardly bent fold. The folded edge is perpendicular to the side plate of the outer structure, and the end of the folded edge away from the side plate of the outer structure abuts against the outer wall of the side plate of the inner structure, and the boss 201 is arranged on the folded edge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com