Rotary drying device convenient for improving filling performance of casings

A drying device and casing technology, which is applied in drying, drying machines, sausage casings, etc., can solve the problems of lower drying efficiency and long drying time of casings, and achieve the effect of avoiding moisture deterioration and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

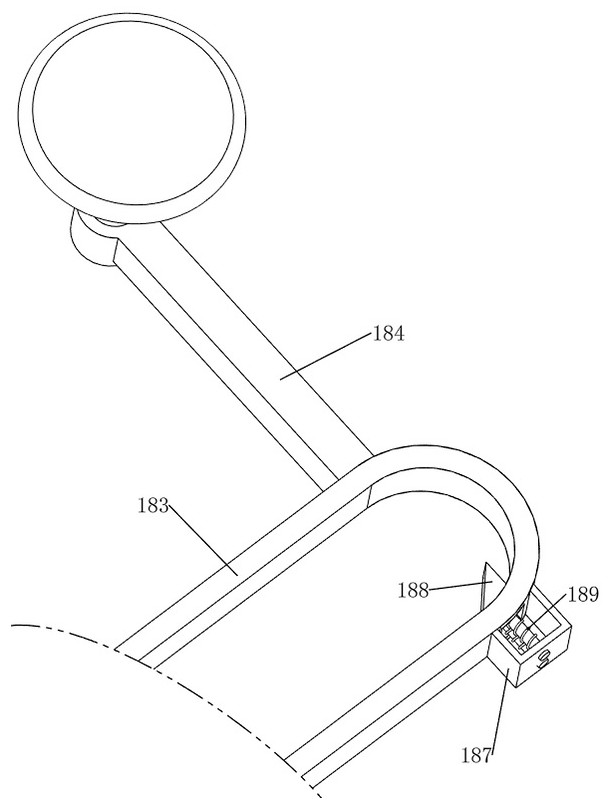

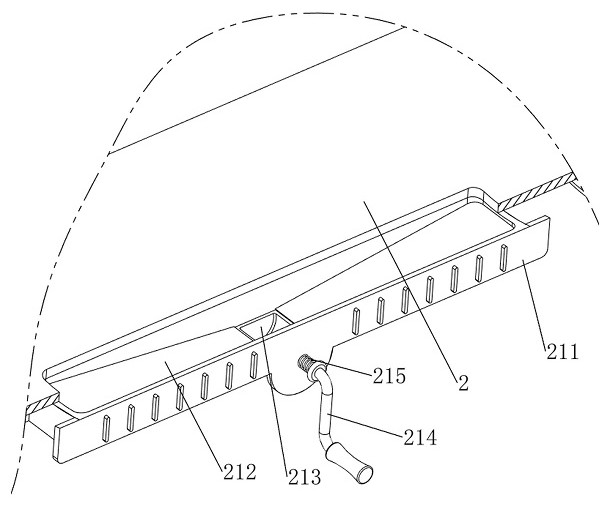

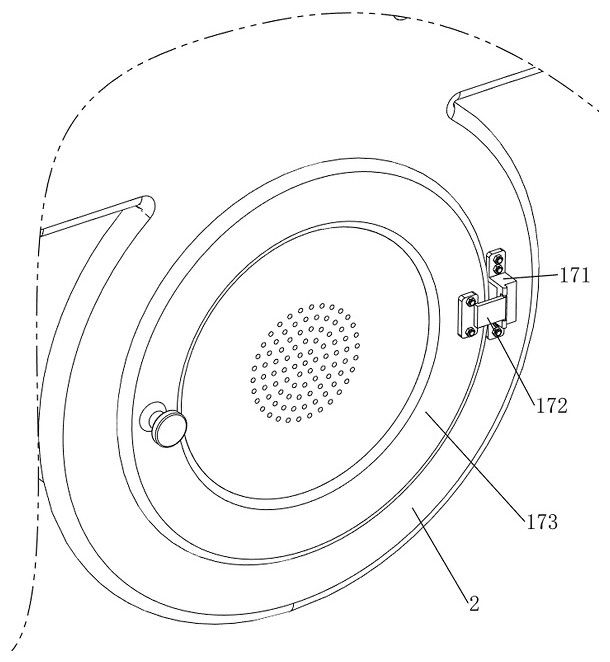

[0037] A rotary drying device that facilitates the improvement of casing filling performance, such as Figure 1-16As shown, it includes a support frame 1, a main frame body 2, a first sliding rod 3, a first sliding sleeve 4, a second sliding sleeve 5, a second sliding rod 6, a third sliding sleeve 7, a third sliding rod 8, Circular slide rail 9, turntable 10, connecting rope 11, first clamp 12, second clamp 13, elastic member 14, drier 15, conveying mechanism 16 and material retrieving mechanism 17, set between two support frame 1 tops There is a main frame body 2, a first sliding rod 3 is provided on the front side of the upper part of the main frame body 2, a first sliding sleeve 4 is provided slidingly on the first sliding rod 3, and a second sliding sleeve 4 is provided on the rear side of the first sliding sleeve 4. Cover 5, the second sliding sleeve 5 is provided with a second sliding rod 6 in the sliding type, the rear side of the second sliding rod 6 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com