Plate cooler

A plate cooler and plate heat exchange technology, applied in indirect heat exchangers, heat exchanger types, machines/engines, etc., can solve problems such as the inability to ensure stable operation of power generation devices, and achieve the effect of convenient temperature testing and easy viewing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] The inventor found in the design process that when a high-power motor (generally installed in environments such as seaside or sea) is working, due to the large current flowing through its windings, a large amount of heat will be generated, resulting in the heat inside the motor not being able to be effectively released in a timely manner. If it is lost, the internal temperature of the motor will rise sharply, and the internal parts of the motor (such as bearings) will be in a high-temperature environment, the efficiency will be greatly reduced, or even fail, and it will also affect the overall life of the motor.

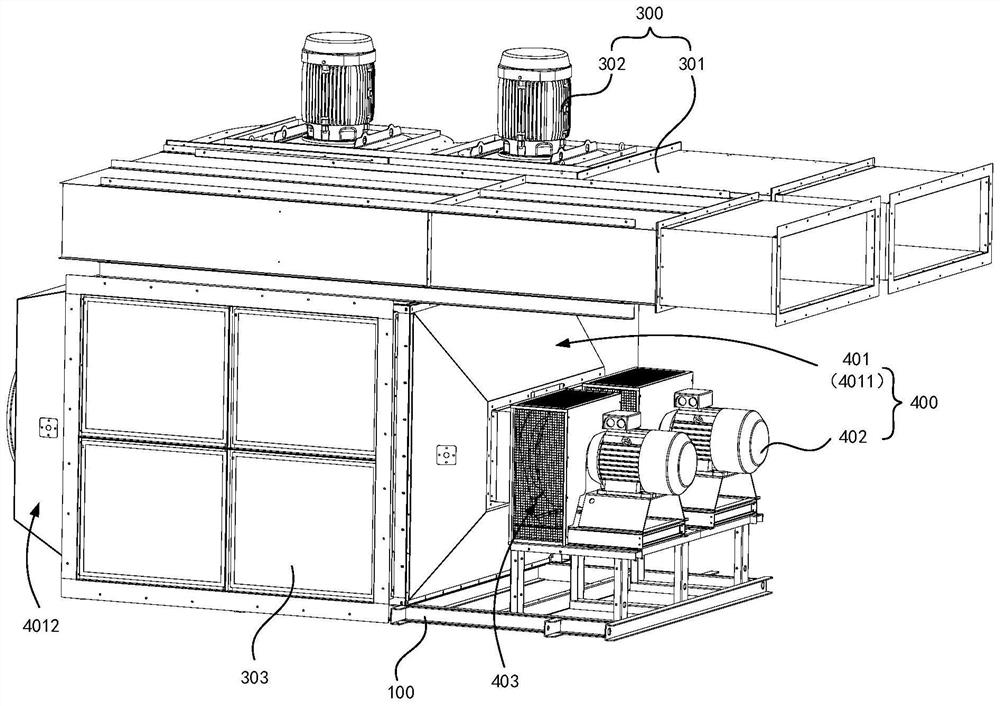

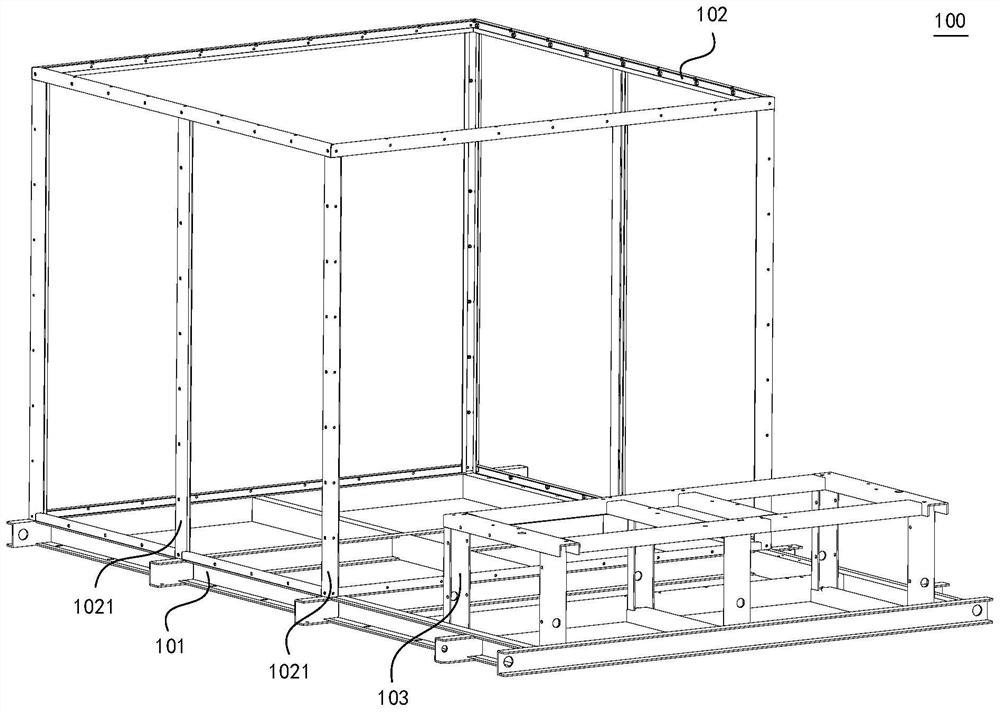

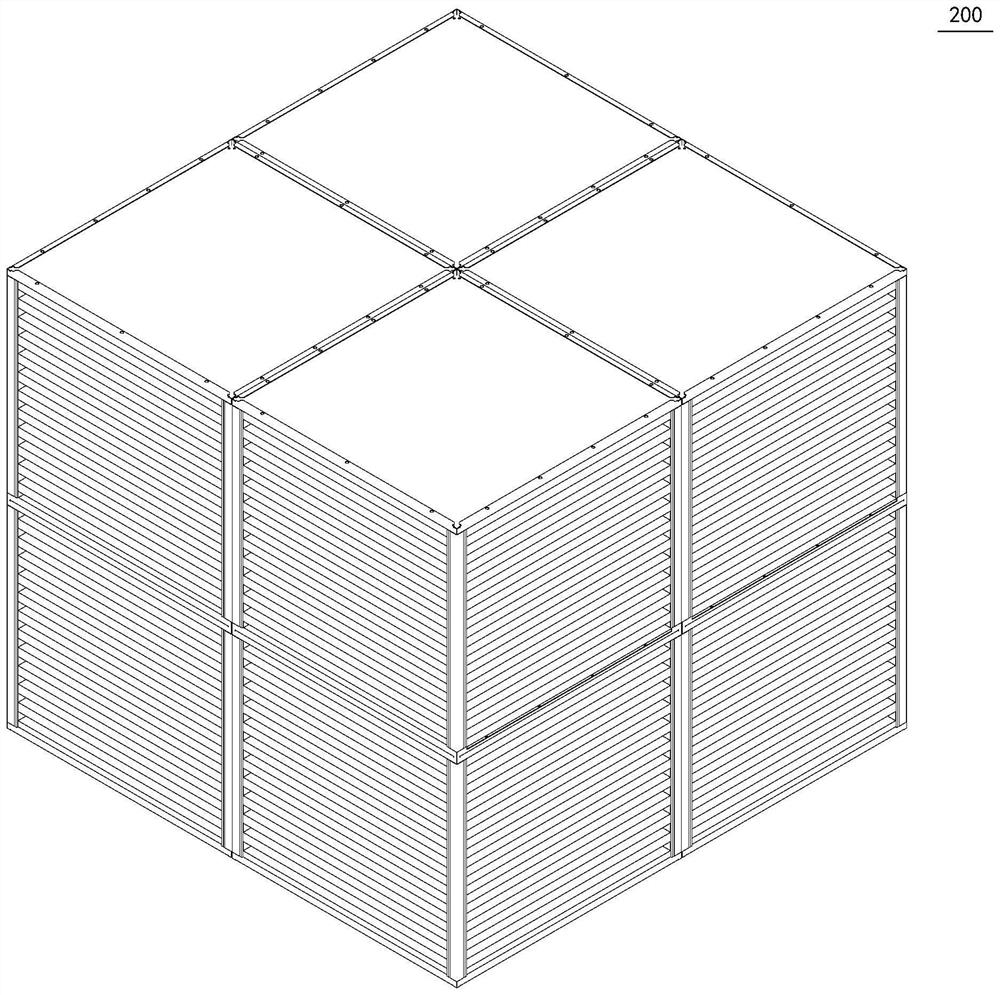

[0044] Such as figure 1 as shown, figure 1 It is a schematic diagram of the overall structure of a plate cooler disclosed in the embodiment of this application; this application provides a plate cooler, including: a frame body 100, a plate heat exchange core group 200, an external circulation fan module 300 and an internal circulation fan module Group 400, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com