Outdoor bamboo-made assembled type double-pieced beam-column structure and assembling method and application thereof

A beam-column structure and prefabricated technology, which is applied in the direction of building structure and construction to achieve the effect of simple construction, stable connection and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

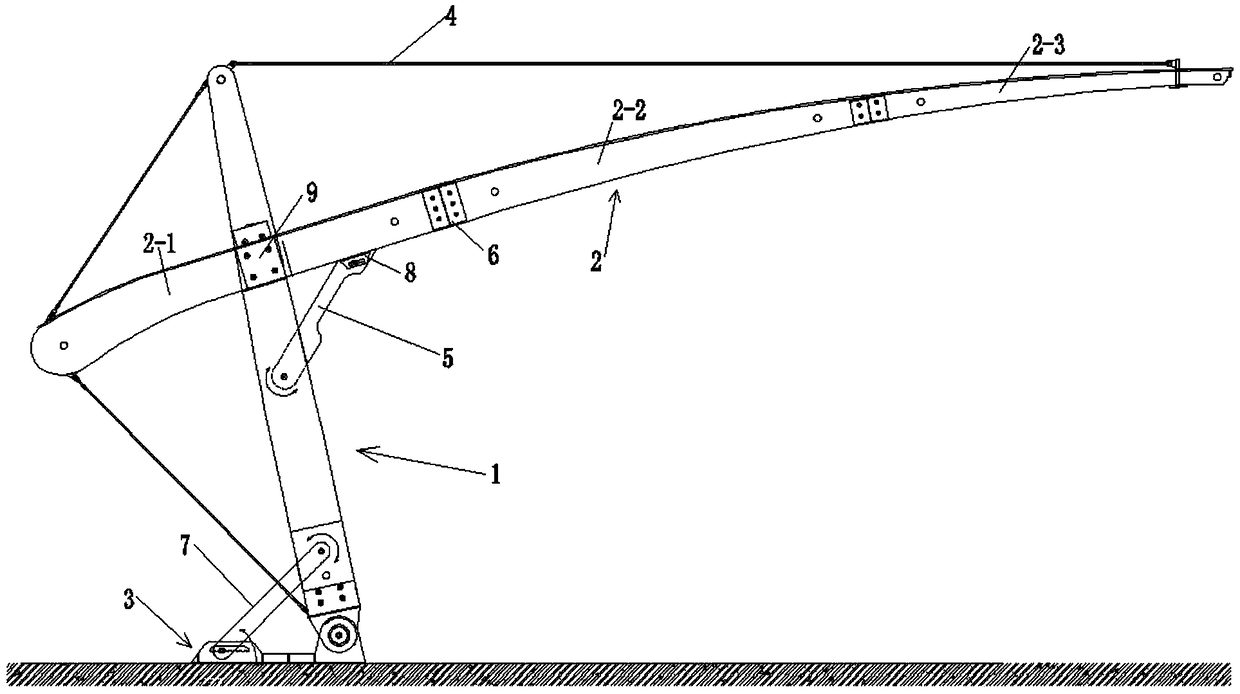

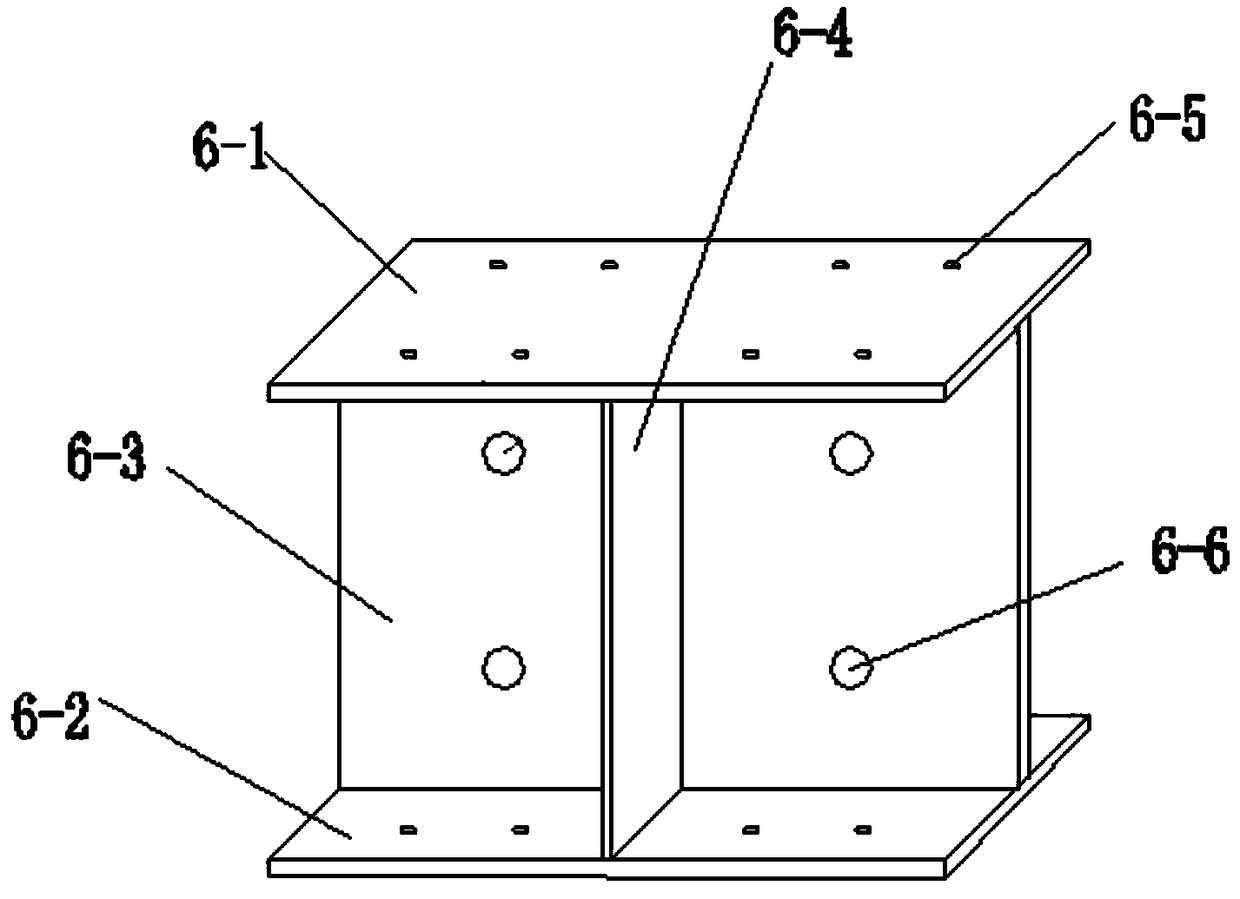

[0062] Such as Figure 1 to Figure 4 As shown, the outdoor bamboo assembled double beam-column structure of this embodiment includes a foot seat 3 fixed on the ground, a vertically inclined column 1 and a horizontally inclined main beam 2, and the column 1 and the main beam 2 are all made of bamboo, and the structural form of the column 1 and the main beam 2 is a double structure. The bottom of the column 1 is connected to one end of the foot seat 3 in a rotating and fixed manner, and the bottom of the column 1 is also The upper diagonal brace 5 is connected to the other end of the foot seat 3, one end of the main beam 2 is fixed to the top of the column 1, and is fixedly connected by the lower diagonal brace 7, and the two ends of the main beam 2 are connected to the column 1. The top ends of the columns are all connected by a steel cable 4 traction, and the bottom end of the column 1 is connected with the horizontal downwardly inclined end of the main beam 2 by a steel cable...

Embodiment 2

[0090] Utilizing the excellent mechanical properties and durability of bamboo engineering materials, combined with the good stability, light weight and high strength structural characteristics of main beams and columns, and through the ingenious design of standard metal connectors, it can fully demonstrate the characteristics of large-span and curved sections. The mechanical structure is suitable for the development and application of outdoor multi-scenario prefabricated bamboo structure buildings.

[0091] A plurality of outdoor bamboo assembled double beam-column structures in Example 1 are assembled side by side, and shoulder beams 11 are arranged between the columns 1 of two adjacent outdoor bamboo assembled double beam-column structures. The shoulder beam 11 and the column 1 are fixedly connected by a T-shaped connector 12, such as Figure 5 As shown, the T-shaped connector 12 includes a fixed plate 12-1 and an extension plate 12-2, and the extension plate 12-2 is plugged...

Embodiment 3

[0096] The assembly method of the outdoor bamboo assembled double beam-column structure of this embodiment at the construction site, the assembly method includes the following steps:

[0097] S1. Digging and filling cement concrete according to the predetermined position and pre-burying the anchor hook prefabricated part 10;

[0098] S2. Fix the anchor hook prefabricated part 10 on the foot base 3 with expansion bolts;

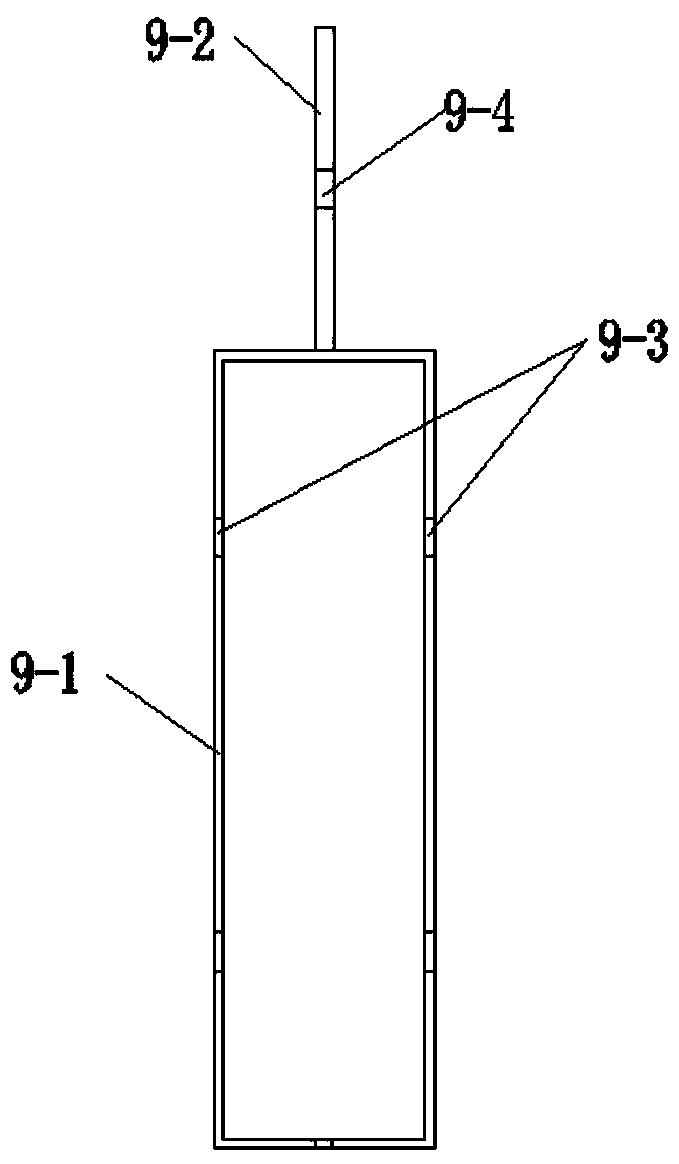

[0099] S3, the first joint column is fixed on the foot seat, then the first joint column 1-1 and the second joint column 1-2 are initially fixedly connected by the cross transfer steel sleeve connector 9;

[0100] S4. Preliminarily install the lower brace 7 between the first column 1-1 and the foot seat 3;

[0101] S5. Installation and connection of double-spanning beams:

[0102] S501, passing the first section of the main beam 2-1 through the steel sleeve 9-1 of the cross transfer steel sleeve connector 9, and locking the first section of the main beam 2-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com